US $3600

Directions

Similar products from Measuring Devices

Advance Liquid Limit Apparatus With Tools & Counter Helpful For Soil Purpose

Liquid Limit Apparatus With Tools & Counter with best quality

Excellent Blood Cell Counter 5 KEYS Lab Equipment Free Shipping

Blood Cell Counter 5 KEYS Free Shipping Lab Equipment (Advance)

Liquid Limit Apparatus With Tools & Counter Helpful For Soil Purpose medi-lab

Best Quality Blood Cell Counter 5 KEYS Free Shipping Lab Equipment(Advance) ml01

Liquid Limit Apparatus With Tools & Counter Helpful For Soil

Turner Biosystems Glomax Microplate Luminometer W power supply 9100-100

QBC Auto Reader Analyzer 424567

Amersham Pharmacia Biotech AKTA Explorer Mounting Bracket Part

Brookhaven Instruments BI-DS1 1700 Volt Photomultiplier Detector Sold AS-IS

HACH Model 16800 Portable Turbidimeter

J&W Scientific 115-3432 GC Chromatography Capillary Column

Agilent 1100 Series G1330B ALSTherm Autosampler Thermostat

Agilent 1100 Series G1311A QuatPump Quaternary Pump

Agilent 1100 Series G1316A COLCOM Column Compartment

Agilent 1100 Series G1315A DAD Diode Array Detector

Agilent 1100 Series G1367A WPALS Well Plate Autosampler

Agilent / HP 1100 Series G1330A ALSTherm Sample Chiller

People who viewed this item also vieved

L & R TRANSISTOR / ULTRASONIC T-7 CLEANER JEWELRY DENTAL LAB EQUIPMENT EXCELLENT

BUCHI INTER LOOP B-295 FOR SPRAY DRYER B-290 AND B-90 FOR SPRAY DRYING ORGANICS

VWR Incubator or Aquarium Rio 90 Submersible Water Pump 323 L/hr 85 G/hr NOS

Uniphase Helium-Neon Laser Model 1101P 4mW

2MP USB Digital Microscope 500X Endoscope Loupe Video Otoscope Camera gadgets US

![OPTICAL MICROSCOPE POLARIZER [delaminated] OPTICS AS IS BIN#G7-22](/_content/items/images/29/2769329/001.jpg)

OPTICAL MICROSCOPE POLARIZER [delaminated] OPTICS AS IS BIN#G7-22

Hacker Instruments H/I Microtome Knife Blade 180mm

New Lab Equipment Compact Rotary mixer training Rotational Mixer 228 svbhm1

ORIEL 16021 X TRANSLATION STAGE ~ NEWPORT NRC

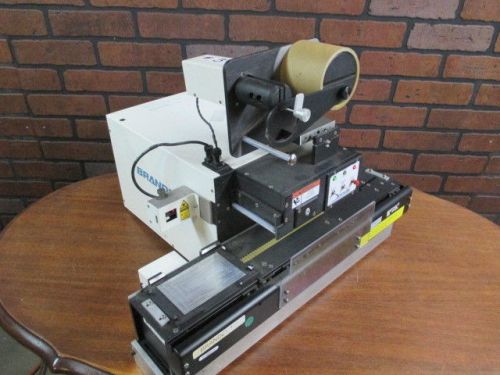

Brandel RS-3000 Microplate Plate Sealer - 30 Day Warranty

Edwards Active Pirani Gauge APG-L-NW16 D02173000

DICKSON TH802 CHART RECODER WITH AC ADAPTER

Nice Test Tube Mixer Shaker Vortex Genie Variable Speed, Warranty, Best Deal

Bellco LC083505 H.D. Overhead Stirrer Drive Works great $149

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies