US $11000

Directions

Similar products from Other Plastic Processing Tools

Used- Krauss Maffei Horizontal Injection Molder, 250 Tons, Model 250-1650 B2. Ap

Used- Wayne Machine & Die Blown Film Die. Approximate 2-5/8" diameter. 3/4" Feed

Used- 6" Vertical Push Through Style Hydraulic Screen Changer. Includes a 2hp, 3

Used- NRM three roll vertical sheet stack, 16" diameter x 53" wide roll face rol

Used- NRM Pacemaker III 2-1/2" Single Screw Extruder, Model 2.5-PMIIII-24.1. App

Used- Battenfeld Profile Puller, Type P100BV. Pipe diameter capacity 10-63mm, (

Used- Welex 2-1/2" Single Screw Extruder, Model 250 24:1 RH. Approximately 24 to

Used- Davis Standard (2) Roll Casting Stand. (2) Approximate 18" Diameter x 30"

SIBE AUTOMATION VACUUM FORMING MACHINE 24"X24" DOUBLE ENDER INFRARED HEATERS

Used- APV Baker Perkins 30mm Twin Screw Compounder Extruder, Model MP30. Approxi

Used- Prodeva Single Rotor Plastics Shredder, Model 315-S, Carbon Steel. Cutting

Used- Drying Hopper, Approximately 8,000 Lbs. Capacity. Approximate 72" diameter

Micro Center Maker Bot Filament 3-D Printer

Glas-craft 0-132 chopper gun gelcoat gun trigger.

Glas-craft 6-318. New in bag. Glascraft fiberglass gelcoat chopper gun.

Stratasys Dimension Compatible Head Unit Thermocouple.

Stratasys Dimension - Door Sensor.

People who viewed this item also vieved

Reed 400 Ton Plastic injection machine

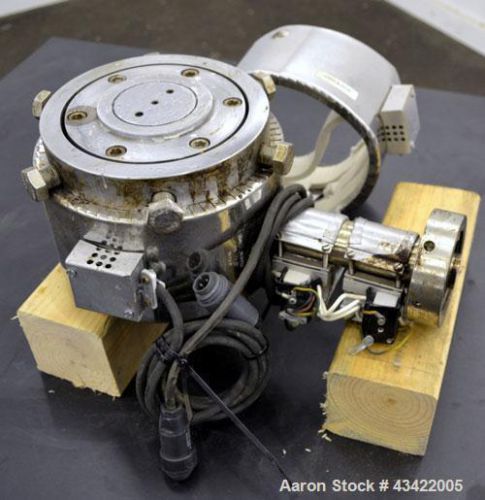

Aggregate card cavity pressure, SN. 83116, Ident-No. 25216C, Arburg Hydronica-D

Input/output card, SN. 79871, Ident-No. 25209C for Arburg Hydronica-D control

310 Ton 2008 Woojin Injection molding machine only 728 hours.

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies