US $49.62

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

UPC | 2014-11-18T21:04:07Z |

| EAN | 2014-11-19T00:32:31Z |

Directions

Similar products from Other Gas & Fluid Monitoring Tools

EPDM Sanitary 316L Stainless Perforated Plate Gasket - 1.5" TC, .0625" Holes

EPDM Sanitary 316L Stainless Perforated Plate Gasket - 1.5" TC, .033" Holes

EPDM Sanitary 316L Stainless Perforated Plate Gasket - 1.5" TC, .125" Holes

1/2" Tri-Clamp Spirax Sarco SSC20 Sanitary Sample Cooler, 316L (4037290)

EPDM Sanitary 316L Stainless Perforated Plate Gasket - 1.5" TC, .25" Holes

3/4" Tri-Clamp Spirax Sarco BT6-BL Balanced Pressure Thermostatic Steam Trap

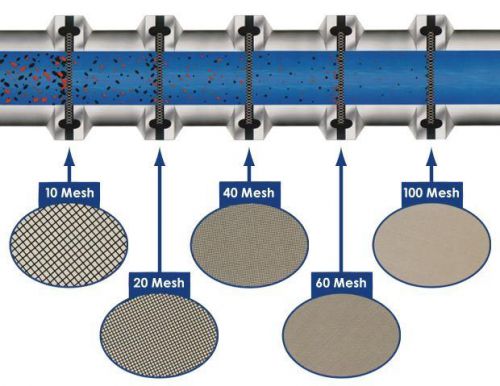

PTFE Sanitary Tri-Clamp Screen Gasket, White - 2" w/ 200 Mesh & 10 Mesh Backer

EPDM Sanitary 316L Stainless Perforated Plate Gasket - 1.5" TC, .045" Holes

Buna Sanitary 316L Stainless Perforated Plate Gasket - 1.5" TC, .094" Holes

Buna Sanitary 316L Stainless Perforated Plate Gasket - 4" TC, .187" Holes

MILLIPORE WAFERGARD 2 F-6 IN-LINE GAS FILTER

(2) New Stainless steel 3" sanitary clamps

SV3X Vibration Data Collector by Vibration Specialty Corp.

NEW COMPLETE STEAMER WAND W/ HOSE ASSEMBLY FOOD PROCESSING, VAPOR SYSTEMS TECH.

Fisher (Emerson) Parts, Bellows Bonnet, 24000-330

Stainless Steel Mounting Base made of Stainless Steel Brand New

VALVE PACKING SEAL TOOLS ASSORTMENT

VAREC PRESSURE VACUUM RELIEF VALVE 12'' , P/N SPL2010B13TFR0P0292 NEW

Lakewood Instruments 350 / Osmonics Process Cooling Tower Controller / Warranty

Tetra Pak plate & frame heat exchanger clip 8 -rm 980 sq ft 316ss alfa laval

People who viewed this item also vieved

3/8" ID HOSE X 1/4" MALE NPT BRASS FUEL FITTING Qty 3 & Qty 1 3/8NPT to 3/8 Hose

HOSE BARB for 1/2" ID HOSE X 3/8" MALE NPT HEX BODY BRASS FUEL FITTING <Q-HB016

Aquasyn Valve Patent # 6155535

LEMO HGG2B306CLLPV CONNECTOR CIRCULAR PUSH PULL FIXED RECEPTACLE NUT

6-" FLOWLINE 6061-ALUMINUM-RAISED-FACE-SLIP-ON-FLANGE-150- 8 BOLT-PATTERN

NITROGEN/ARGON REGULATOR 3000PSI INLET 0-25PSI OUTLET CGA580 NEW DEMO UNIT

ARGON/NITROGEN REGULATOR 3000PSI INLET 0-25PSI OUTLET CGA580 NEW DEMO UNIT

ARO Tool Products. Hydraulic Pressure Check Up to 1200 lbs. Model No. 38922-1

Lot of PHP 30006 3" 30007 4" Rubber Gasket Backup Float Valve NEW sealed FreeS&H

Middlesex Gases Usg Gas Regulator NEW!!!

NEW FLOWSERVE 1" ACTUATED STAINLESS STEEL BALL VALVE SOCKET TYPE SID063S10

2 NEW Fisher Parts 39B3849X012 Diaphragm 19B8486X012 Valve Packing NEW

9 NEW Fisher / Emerson Piston Ring 1U2300X0012 NEW NEW

PARKER 0R50B QUICK EXHAUST VALVE 1/2'' - NEW - FREE SHIPPING

PARKER 0R37B QUICK EXHAUST VALVE 3/8'' - NEW - FREE SHIPPING

GPI TM200-N PVC Turbine Flowmeter, 20 to 200 gpm Flow Range, 2" FNPT

GPI FM-300U Polyester Electronic Flowmeter, 2 to 20 gpm Flow Range, 1" NPT

GPI TM150-N PVC Turbine Flowmeter, 10 to 100 gpm Flow Range, 1-1/2" FNPT

RealPro 1" Poly Dispensing Nozzle 75 1" N/A 1" 1

GPI TM075-N PVC Turbine Flowmeter, 2 to 20 gpm Flow Range, 3/4" FNPT

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies