US $250

Directions

Similar products from Hangers & Connectors

(2 PACK)Vibration-Resistant Stud Anchor for Concrete 94475A250

Hilti Pins For GX-120 Gun 3/4" And Fuel Cell

LOT of 4 NEW SIMPSON STRONG-TIE ADJUSTABLE 4 X 4 POST BASE AB44Z

ITW RED HEAD 1/2"x4.5" Trubolt+ Wedge Anchors CWS-1244 *Box of 36* Wedge Anchors

Small Parts Brass Thumb Nut, Nickel Plated Finish, Right Hand Threads, #8-32

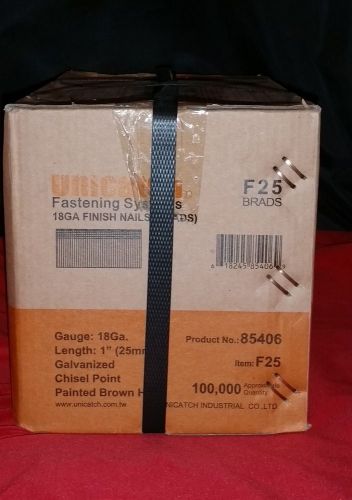

1 Case of 1"Galvanized 18 Gauge Brads 20/Case for Senco,Grex,Bostitch & DeWalt

(5 PACK) 316 Stainless Steel Flat Washer 91525A143

LOT OF 20 - Erico Caddy SLD15L2 Speed Link Locking Device Cable 1.5mm x 2m Wire

Anchor Kits bulk packed 500 Plastic Anchors 500 Screws & 5 1/4 Inch Drill Bits

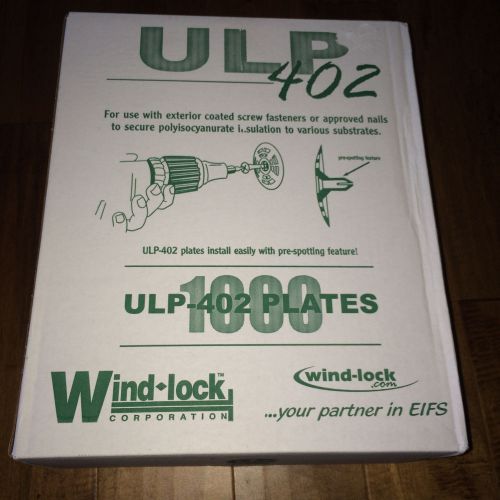

Wind Lock ULP-402 Plates Insulation Fasteners (1000 Count) NEW! W/O Screws

WOODWORKER STANLEY WINDOW SPRING BOLT 1687 ( EDP 67-6090 ) 2C ZINC FINISH

(Lot of 5) New Hillman Fastener Strike Anchors 1/2 x 4 3/4" Cement

Hilti Anchor Rod HAS 5.8 1/2" x 4-1/2". Part # 385423

13 SIMPSON STRONG TIE LSSU410 4 x 10" Slopeable/Skewable U HANGERS joist rafter

Mixing Nozzle Kit,High Quality,Convenient to Use,Easy Attachment,22oz Bag3

Parts Express #8 x 1/2" Phillips Truss Head Screws 100 Pcs.

Parts Express #8 x 3/4" Phillips Truss Head Screws 100 Pcs.

Box of 91 Hilti Threaded Rod Hanger 1-1/4" Nails X-HS W6-DNI 32P8 S15

Ramset FPP034B TrakFast Standard 124 10 Pin Strips (3/4 in)

LOT OF 50 STAINLESS STEEL 10 X 1'' WOOD SCREWS FLAT PHILLIPS HEAD

People who viewed this item also vieved

NEW Small Corner Duct Cable Raceway - 5 Feet - White

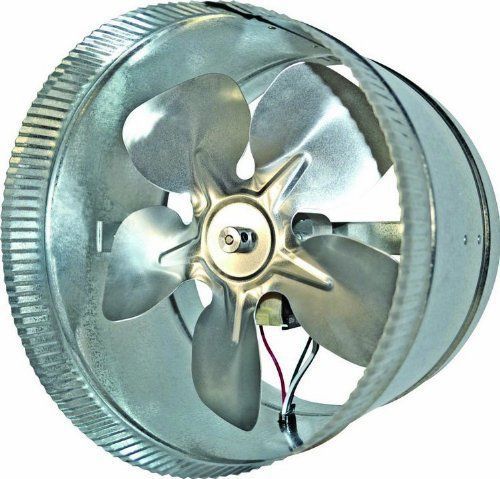

NEW Suncourt -- Inductor 10" In-Line 2-Speed Duct Fan (DB310P)

Lot Box of 3 Ferraz-Shawmut FSPDB2A 175 Amp 600 Volt Power Distribution Blocks

Quantity 1 Ferraz-Shawmut FSPDB2A 175 Amp 600 Volt Power Distribution Blocks

246349 18A "A" Side Seal Cartridge Body for Graco Fusion AP Air Purge

CON-SERVE WATER HEATER INSULATION JACKET 40 GALLON R4.3

NEW 2Pc Hubbell HBL20GBA618IV 6ft. 2-Circuit 15A 6Rec Metal PlugTrak Ivory

PHILLIPS ADVANCE CENTIUM ICN-2P32-N BALLAST 120-277 VOLT (LOT OF 2) NEW

L&G's Victorian Gingerbread Fretwork Porch Corner Trim Brackets 10"

L&G's Victorian Gingerbread Fretwork Porch Corner Trim Brackets 12"

5best Quality High Speed Wrench Exposed Cartidge Pana MAX style Handpiece

1High Speed Wrench Type Exposed Cartidge Color large 4Hole best price

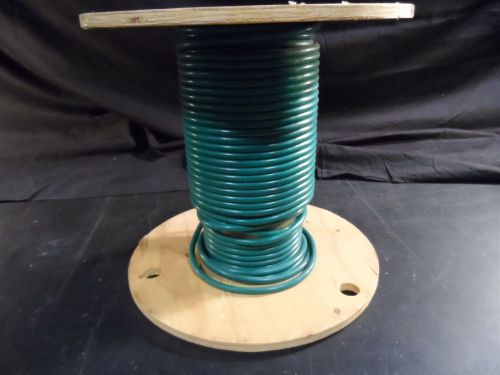

(1x) Cableco HV8-55-5 PowerFlex 1000 8 AWG 1000V FT1 105°C Cable 198ft.

(1x) Cableco HV6-85-5 PowerFlex 1000 6AWG Red 1000V FT1 105°C Cable 134ft.

Ecological building sealant ECO48 for finishing work ( 1 kg )

RTV Silicone, 744, White,Dow Corning - 1922181 - RTV Silicone, 744, White, 310ML

Cerium Oxide High Grade Polishing Powder - 4 oz.

Basement Egress Window Well Cover Size 52x36

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies