US $2,000.00

| Condition: |

Used: An item that has been used previously. The item may have some signs of cosmetic wear, but is fully

operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

...

|

Brand | Best-007 Infrared BGA |

| Model | 007 |

Directions

Similar products from Soldering Irons & Stations

APEX TOOLS GROUP / COOPER TOOLS INC. PH60 WELLER SOLDERING IRON HOLDER W60 IRON

Metcal MX-500P-11 Solder / Rework System - NEW IN BOX

Metcal MX-500S-11 Solder / Rework System - NEW IN BOX MX-500P-11

Metcal STSS-002 RFG-30 Rework Solder Desolder Station Power Supply - TESTED

Metcal RM3E Soldering Iron Handpiece for STSS MX500 Rework Systems - TESTED

Weller Soldering Iron Station WLC100 - 40 Watt

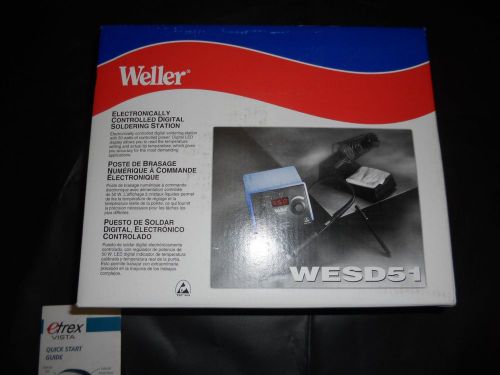

WELLER WESD51 Electronically Controlled Digital Soldering Station "NEW"

10x 5ft/1.5m Bobbins 60-3-5 SW16035 Desoldering Braid Soder-Wick Chemtronics 50'

Smd hot air rework pencil (smt max/hakko 851)

Edsyn Loner 952 150W Dual Soldering Station

Pace TD100 Soldering tip suface mount New in tube 1124-0506-P1 SOP tip New

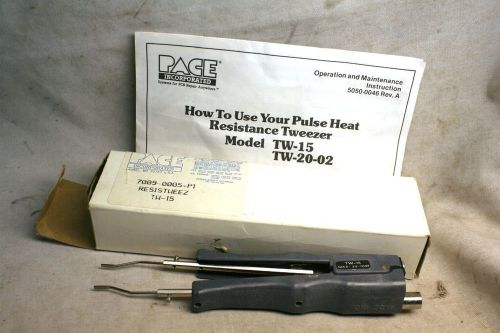

PACE Tweezers TW-15 7009-0005-P1 new in box

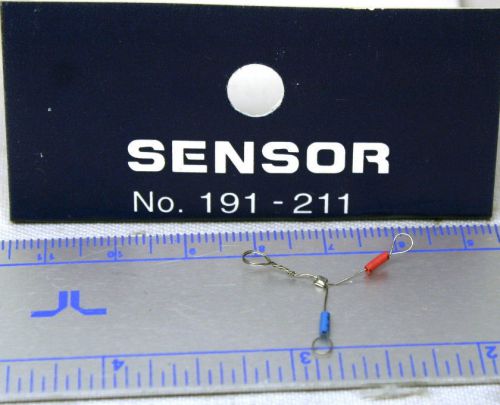

PACE Thermometer sensor for Pace Tip temperature checker New No reserve

Pace Sealed Bag of 25 SX20 SX25 Desoldering Tips 1121-0213 Sodr-X-Tractors

Pace TD100 Soldering tip suface mount New in tube 1124-0504-P1 SOIC Removal

Electric Pen Type Butane Gas Solder Soldering Iron Tool Welding Kit 12ML Filling

New 7in1 Electric Solder Tools Kit Set w/ Soldering Iron Stand Desolder Tweezer

Weller WES51 Soldering Station (WES51 + PES51 + PH50) + PanaVise 201 + Tools

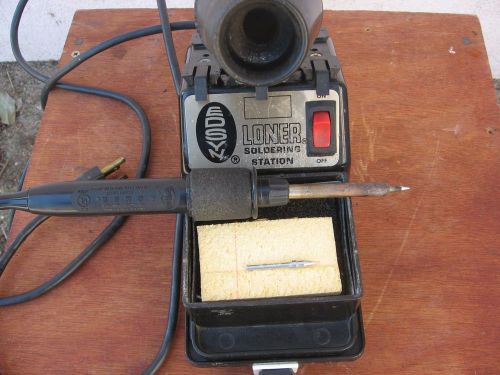

Edsyn Loner PS536 solder station w/ PD528 Idle Rest Tool Pod

People who viewed this item also vieved

Kester Solder 1 pound spool Plastic Rosin Core 40/60

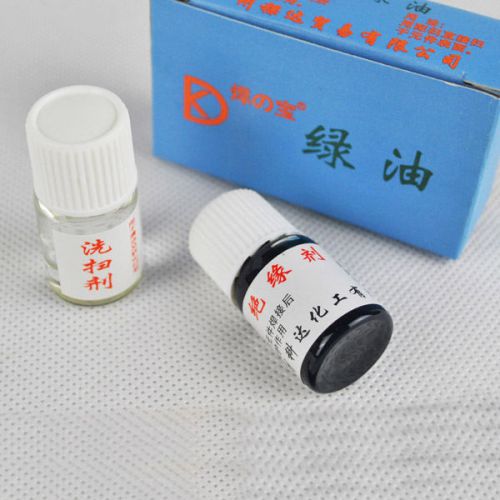

KD 2-In-1 Green Oil Circuit Board Repairing Protecting Paint + Cleaning Oil

Alpha 60/40 Alloy-Cen-Tri-Core Energized Rosin Core Solder Spyraline Dispenser

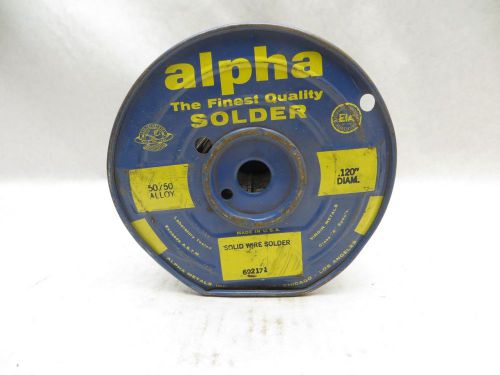

10 Pounds Alpha 50/50 Alloy (.120) Diameter Solid Wire Solder

HARRIS SAFETY SILV 45% SILVER BRAZING ALLOY 1/16" .75 TROY OUNCE

HARRIS SAFETY SILV 40% SILVER BRAZING ALLOY 1/16" TWO ROLLS 2.75 TROY OUNCES

Kester Lot of Solder 24-6337-8800 .031 AWG 456

New Weller EP108 1/8" 3mm Chisel Tip for EC1301 Series Irons

Weller EP 107 Replacement Soldering Tip for EP107 EC3000 EC1301

24pcs 1.5" 18Ga Blunt stainless steel dispensing Syringe Needle Tips

Weller Tip Activator 0051303199

Pace Replacement Tip 1121-0342-P5 and 1121-0367-P5 12 Tips total

OKI Metcal Replace STDC-104, 106, 107 SMTC-005, 006, 1107 TATC-602 12 Tips total

WELLER HEAT GUN REFLECTOR 6964 (2469)

AOYUE B003 Replacement Soldering Iron

American Beauty # 600 Solder Pot USED

AMERICAN BEAUTY MODEL 300 SOLDER POT, USED BUT HEATS UP FINE

Hakko FM2024-21 Desoldering Module Conversion Kit

Ideal Thermo-Shrink Power Unit- Cat. No. 46-001

HAKKO 936 soldering station Electric iron+A1321 ceramic heater core 220V

NOS WASSCO WIRE STRIPPER GLO-MELT MODEL 10517 RESISTANCE SOLDERING IRON GLO MELT

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies