US $3,410.00

Directions

Similar products from Testing & Assembly Equipment

Chatillon DPP 160 10 lb x 2 oz Force Gage stand pull strength spring tester

LTX Trillium Printed Circuit Board PCB ABIF2 865-7202-06

LTX Trillium Printed Circuit Board PCB DUTP1 865-7070-09

LTX Trillium Printed Circuit Board PCB DWBFSET 865-7425-00

LTX Trillium Printed Circuit Board PCB APSB2 865-7163-05

LTX Trillium Printed Circuit Board PCB CBIF 865-7187-03

LTX Trillium Printed Circuit Board PCB EPIF 865-7196-07

CASCADE MICROTECH DCM 200 XYZ PROBE POSITIONER MICROMANIPULATOR #4

Fisons Kevex Quantum EDS Detector Noran 2003 3600-0043-0146 Delta 10078

CASCADE MICROTECH MPH XYZ PROBE POSITIONER MICROMANIPULATOR #2

3282 CCI/CIMTEK P/N: 3252051 Circuit Check Test Station, CCI#: 41748,

TEMESCAL BJD-1800 WITH (REBUILT 4 POCKET ELECTRON BEAM GUN ) Warranty

CASCADE MICROTECH DCM 210 XYZ PROBE POSITIONER MICROMANIPULATOR #2

Perkin Elmer 6779500 PCB Assembly, Used

Perkin Elmer 6770293006 PCB Assembly, Used

Nozzel Full Cone SS 1/8 MPT (3pk)

Quick Connect SS Parker 3/4 Series 60

Twezzer Non Conductive Bernstein 5-193ESD (12 pk)

People who viewed this item also vieved

S-Vision ASXGA burn-in adapter ISE & IQL B433 A board

LH Leybold BE05 automation switch board mount card pcb

AMAT Applied Materials RF Micro-Match network 8300 0010-00299W , 0010-00799W

Datametrics modular encoder turntable motor K3S0-360-5-7404-6B

KOLLMORGEN EC2-T31T-15-05B-150-FS2-EM-BS24 ELECTRIC CYLINDER , USED

Bridgestone DW200-CMP 8" DUMMY WAFER FOR CMP APPLICATION LOT OF 4 , NEW

2 MDC MFG VACUUM PIPE VALVE, (Long 4" inch, face 1" 1/2 inch)

2 VACUUM PIPE VALVE 3 Way w/ 2 Clamp + 2 Ring

3 CABLE RG213/U COAX (Male to Male)

Lot of 3 PFA Teflon 13 wafer carrier cassette 6" ( 150mm ) Fluoroware / Entegris

NIKON NWL-641 WAFER LOADER plus

Edwards seiko turbopump stp-h803c turbo pump

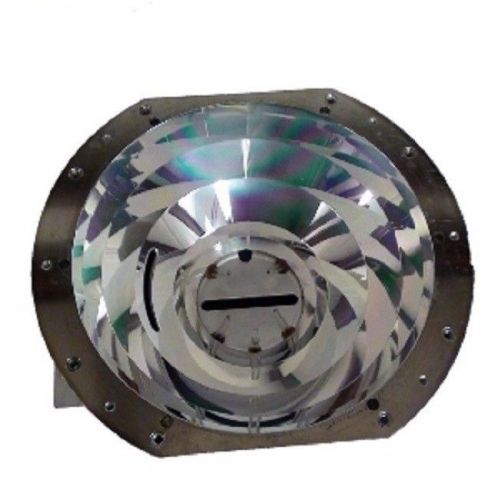

FUSION AXCELIS M150 REFLECTOR MIRROR 086771

CPV-009 Teflon Cassette Handle, 100mm

Lam Research 716-011036-001 Ring Filler Lower Rev. F Used Working

Lam Research 716-011036-001 Ring Filler Lower Rev. F New

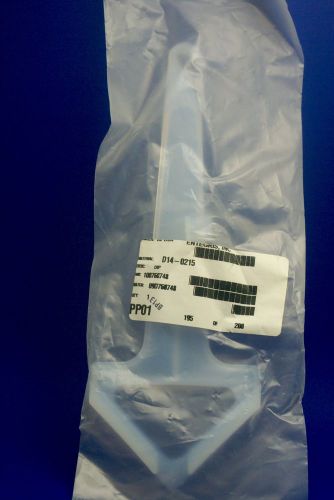

Entegris D14-0215 Wafer Dipper

Leybold D65B Vacuum Pump << Rebuilt with Warranty >>

Applied Materials AMAT Quantum X Implanter Chassis'

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies