US $4800

Directions

Similar products from Large Scale Printers

HP Designjet Z5200ps 44"printers - Warranty until February 2017 **BONUS**

KONICA MINOLTA 1024 PRINT HEAD KM1024MHB 14 PL UV PRINT HEAD USA (WOW!!!)

KONICA MINOLTA 1024i PRINT HEAD KM1024iSHE 6 PICOLITER UV ***NEW*** USA WOW!!!

HP HEWLETT PACKARD 36" DESIGNJET MODEL 750C PLUS COLOR PLOTTER PRINTER

Kodak 1200i wide format printing system

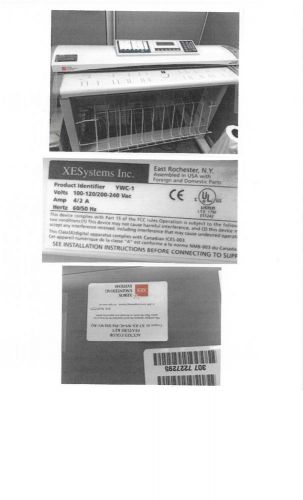

Xerox 510 Wide Scan & Print System

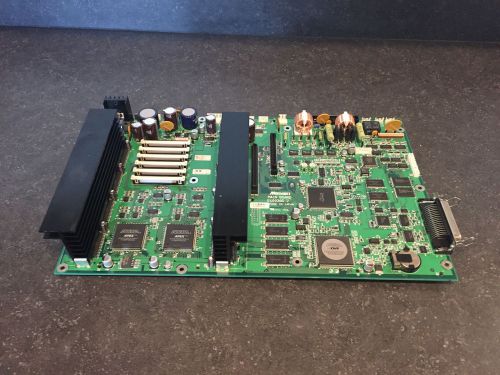

Mimaki JV3-160S Main Board - E400306-2

Mimaki JV3-160S Main Board - E400306-2 JV3

HP Designjet T1100 24" Large Format Printer / Model: Q6684A

Roland SP-300V 30" VersaCamm Large Format Printer & Cutter local pick up only.

Mimaki JV3s-75/160/250 “USED” Cutter Unit, Wide Format Solvent Printer

Mimaki JV3-160SP USED” IO2 Board, Wide Format Solvent Printer

Mimaki JV3sp 75/160/250 “USED” Ink Cartridge Unit, Wide Format Solvent Printer

Mimaki JV3-SP “USED” IO Board, Wide Format Solvent Printer

Mimaki JV3s-75/160/250 “USED” Display Control Panel, Wide Format Solvent Printer

Blu-Ray 50 Scavenger Plus Blue Print Printer Copier

Epson 4800 Stylus Pro Large Format Printer with Stand - Excellent condition!

HP DesignJet 1050c Plus C6074B Large Format Printer Plotter

People who viewed this item also vieved

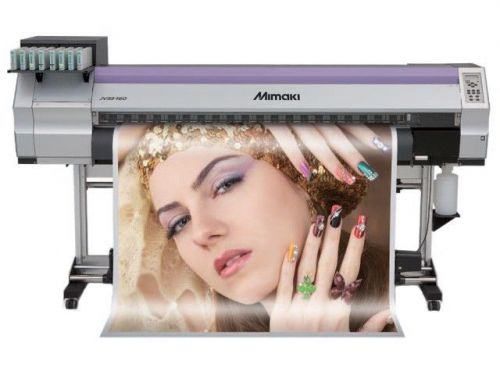

NEW MIMAKI JV33-160 WIDE FORMAT WITH 63" PLOTTING CUTTER AND LAMINATOR COMBO

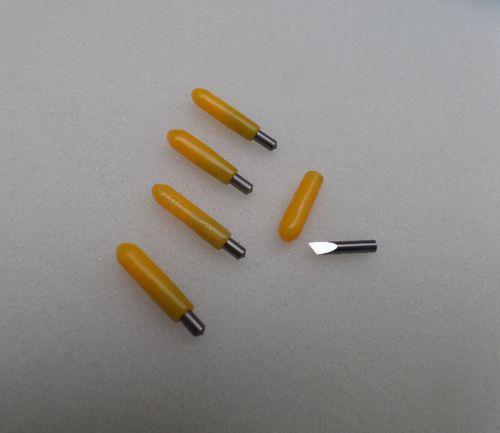

New 5 pcs 60? Ioline Blade Knife Cutting Plotter Blade Vinyl Cutter Knife Bits

New 5 pcs 30? Ioline Blade Knife Cutting Plotter Blade Vinyl Cutter Knife Bits

New 5 pcs 45? Ioline Blade Knife Cutting Plotter Blade Vinyl Cutter Knife Bits

5 PCS/SET 60 Degree Blades for Graphtec Blade Vinyl Cutter Plotter CB09 BIT020

SM7 10x 1/8" Tungsten Carbide Burr 3mm Rotary Cutter files CNC Engraving CED 6mm

SM7 1PC Al- Blade Holder For Roland Vinyl Cutter Cutting Plotter New BIT005

5 PCS/SET 60°Degrees Cemented Carbide Vinyl Cutting Plotter Blade For Roland

SM7 5pcs/set 45 Degrees Cemented Carbide Vinyl Cutting Plotter Blade For Roland

5PCS/SET 30Degrees Cemented Carbide Vinyl Cutting Plotter Blade Roland BIT002

4 Pack Pens, Archival DPP Rapidoplot Black 6810-01F .35mm Universal A Style/1P

4 Pack Pens, Archival DPP Rapidoplot Black 6810-01E .25mm Universal A Style/1P

NEW LOT OF 6 GRAPHIC CONTROLS SERIES 39 CHART RECORDER PEN 82-39-0201-06

1 USED CALCOMP 68436 COLOR ELECTROSTATIC PLOTTER *MAKE OFFER*

HP C7769-40112 FOR DESIGNJET PLOTTER 500,800

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies