US $7.99

Directions

Similar products from Tool & Machine Spare Parts

AMAT 0190-17464 P1191D Lamp Driver Dimmer SCR Control

NEW TEL Tokyo Electron 1D10-100938-12 RF Plate P1C/DRM2

AMAT 0010-15632 300mm Radiance Pyro/Pyrometer 2mm Probe

AMAT Applied Materials 0015-09091 MCVD Lamp Driver

NEW Applied Materials AMAT 0020-31016 Housing Quartz Tube BWCVD

KDF Vacuum 813-28-450-G MRC 643 Stainless Steel SMD Load Lock Bellows Locking

Sony Millman LH30-2 Digital Readout X Y Z Axis Milling Machine display only

Thornton 740-A01 Resistivity Module DOT TWO Controller w/ PROBE & CABLES 115V

PACIFIC SCIENTIFIC SC903-001-01 Servo Motor Amplifier Drive Driver *Guaranteed*

Refurb MECS/Cybeq/Asyst UTC800/UTC-800 Wafer Handling Robot Arm

Applied Materials/AMAT 8300 RF Micro-Match Network PN: 0010-00799

ATLAS COPCO 1619 2798 00 1619279800

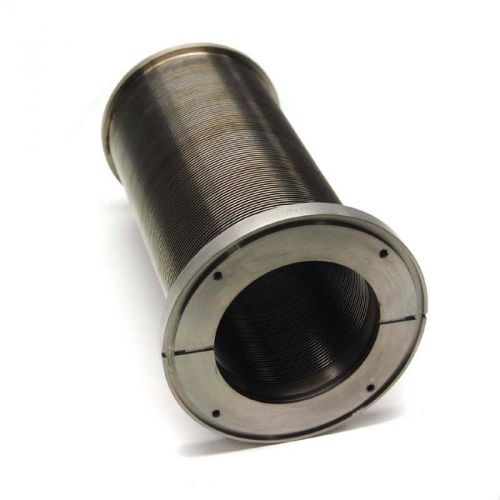

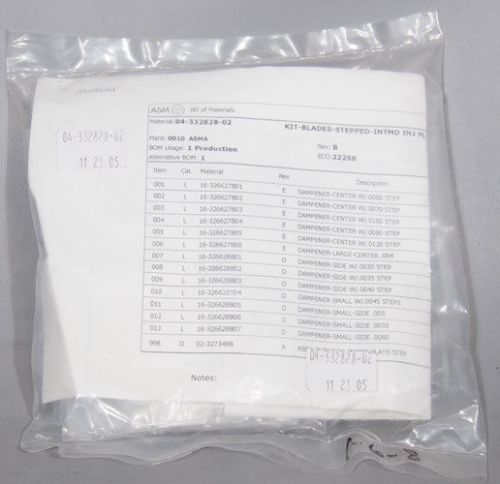

NEW ASM PN: 04-332828-02 Kit-Blades-Stepped-Intmd-Inj Plt, Injector Plate

Aquafine Corp. SL-10A Ultraviolet Water Treatment System: Low Hours

IDE 395.500 G Active Vibration Isolation Controller MAXCON-1000 Archer 10XT used

Used NOVA scan 420 incomplete (parts)

HNL Inc, ASSY, WAIVEGUIDE, p/n RA-21-04/C

SCP, Parker Motion 10G WBR AND RAIL, Wetbanch, Model 802-8287D, s/n 052609201A

People who viewed this item also vieved

3M STATIC DISSIPATIVE TABLE MAT WITH GROUND CABLE BROWN 2' X 4 ' NOS

SIMCO 1C7s STATIC NEUTRALIZING SYSTEM 110VAC INPUT 7KVA 2.5mA MAX OUTPUT

Contact Systems Inner Cutter for C/C (P/N 400-1400)

Contact Systems Outer Cutter for C/C (P/N 400-1206)

Vision Engineering Lynx Dynascope

Portable X-Ray Inspection System For PCB BGA Electronic Desktop Testing 10Kg

Glenbrook RTX-113HV X-Ray XRay Inspection

QRP 7CL Anti-Static Latex ESD Fingercots Large 5-Gross

Prudential 530 005 80 Cleanroom Frocks

1000 VWR Certi-Clean Room Gloves Medium 40101-160 12 Inch Cleanroom Class 100

ASYST Fan Filter Assembly C0094-0948-01

Santa Clara 2700 Recirculation unit | 24Amps Peak | 208 VAC

KLA Tencor 0105670001 PCB 0104924-000 INTERFACE BOARD V1

TEL TE2B023/ECU E2B023-11/ECUM

TOKYO ELECTRON TEL CONTROLLER F-CPCI-V1 / SC2720 free ship

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies