US $13,850.00

Directions

Similar products from Laser Level Kits

New Topcon RL-H4C DB Package PLUS 2.5 Meter Rod & Tripod with Global Shipping

LASERMARK ROTARY LASER LEVEL SYSTEM, LM-30 WIZARD AND LD-100N DETECTOR, LM30 LD

New Topcon RL-VH4DR GC Red Beam Self-Leveling Laser System with Detector

New Topcon RL-VH4DR INT Red Beam Self-Leveling Laser System with Grid Mount

Bosch/Robotoolz Red Laser Enhancement Glasses

New 8 Foot Fiberglass Grade Rod with Inches Scale & Carrying Case

HILTI PRI 2 ROTATING LASER, PREOWNED, IN GREAT CONDITION, FREE HAT,FAST SHIPPING

Trimble Spectra Precision 0367-2000 3D GPS Control Box for Motorgrader Dozer

HILTI PRI 2 ROTATING LASER CASE, BRAND NEW, HEAVY DUTY,>CASE ONLY<,FAST SHIPPING

Lasermark Automatic Self-Leveling Rotary Laser (LM700)

Topcon RT-5Sa Dual Slope Grade Laser Machine Control - Sold As Is

UPDATED 1.65M Aluminum Tripod+5M Staff For Rotary Laser Level A

NEW DeWalt DW074KD Self Leveling Rotary Laser Level 3 year WARRANTY Construction

NRL802 NORTHWEST ROTARY LASER PKG.

NRL800 NORTHWEST ROTARY LASER LEVEL

HILTI PR 16 LEVEL, IN EXCELLENT CONDITION, FREE HILTI T-SHIRT & HAT, FAST SHIP

Johnson Level 40-6516 Professional Self-Leveling Horizontal Rotary Laser Level

Builders Rotary Portable Laser Leveling System & Carrying Case VGC

CR5 Laser Machine / Control Receiver Detector Combination Laser Receiver

People who viewed this item also vieved

Hilti Multi Line Laser Level PM4-M

98-12 Machinists’ Level with Ground and Graduated Vial

New Black & Decker BDL310S Projected Crossfire Auto Level Laser

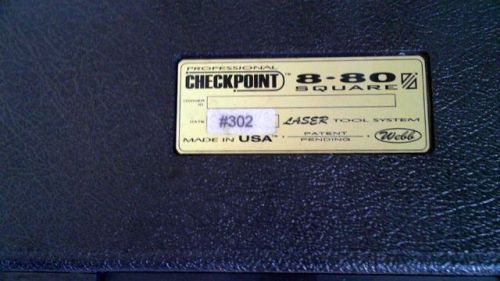

Checkpoint 8-80 Square laser level

RYOBI AIRGRIP COMPACT LASER LEVEL ELL1001 EXCELLENT CONDITION FREE SHIPPING

Bosch GLL1P Combination Point and Line Laser Level New GLL 1P W/Warranty

H-3 Soviet Surveying Level IOMZ

Trimble Model 5.2XL Cross Hair and 5 Point Laser Level

Sokkia Sokkisha TTL6 Precision Tilting Level - Very Good Condition with Case

Stabila 81S 250mm level Good Condition-normal wear- construction tools

Leica Rugby 100 LR Laser Level and Spectra HL700 Laserometer

Laser Alignment w/ Speed Control Model 1779 (Blue Box) ..US-002

Laser Alignment w/ Speed Control Model 2157 (White Box) ..US-001

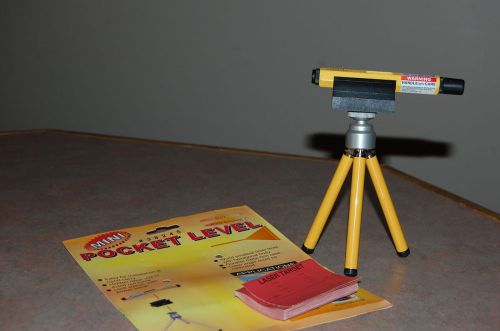

D.I.Y World Smallest Mini Pocket Level #38245 For Sale!!!!

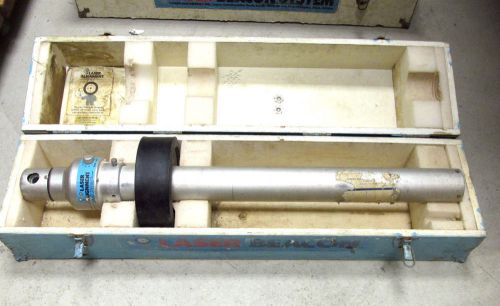

Spectra Trimble DG711 Precision Pipe Laser Kit

Bosch 2 point laser level GPL2 W/Case

Bosch 2 point laser level GPL2

Porter-Cable RoboToolz RT-2710-26 RT-2710-22 Automatic Optical Level

Black and Decker Bullseye Auto-leveling Laser With Stud Sensor

AUTO-LEVEL CONTRACTORS NCL22M NORTHWEST EQUIPMENT

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies