US $34.99

Directions

Similar products from Soldering Irons & Stations

2 in1 Soldering Desoldering ReWork Station Iron Hot Air Gun Dessoudage air chaud

40w Soldering Iron Crescent General Purpose. 40watt

Soldering Iron WELLER Marksman 25Watt SP25DAU

1X 100g 0.3mm 63/37 tin/lead Welder Iron Rosin Core Welding Solder Wire Roll

100pcs Open-Top ESD Anti Static Shielding Bags Antistatic Protect Bag Gold 6x9cm

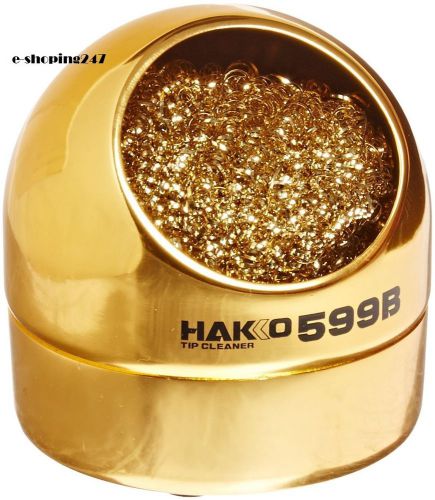

Soldering bit tip cleaner lead free electronics repair

10x universal soldering iron replacement sponges solder iron tip cleaning pads

soldering iron solder tip welding cleaning sponge round diameter 5cm 10pcs

Pace ST-115 SensaTemp Digital Soldering/Desoldering Station w/ Iron+Workstand

Master Appliance Ultratorch UT-300Si Pistol Grip Flamelesss Heat Tool Soldering

AC 220V-240V 40W Electric Soldering Iron Welding Tool EU Plug Yellow Functional

10pcs 0.1mm Copper Soldering Solder PPA Repair Enamelled Reel Weld Wire Roll GL

20pcs 0.1mm Copper Soldering Solder PPA Repair Enamelled Reel Weld Wire Roll GL

2pcs 0.1mm Copper Soldering Solder PPA Repair Enamelled Reel Weld Wire Roll GL

3pcs 0.1mm Copper Soldering Solder PPA Repair Enamelled Reel Weld Wire Roll GL

2pcs 0.1mm Copper Soldering Solder PPA Repair Enamelled Reel Weld Wire Roll FB

3pcs 0.1mm Copper Soldering Solder PPA Repair Enamelled Reel Weld Wire Roll FB

5pcs 0.1mm Copper Soldering Solder PPA Repair Enamelled Reel Weld Wire Roll FB

10pcs 0.1mm Copper Soldering Solder PPA Repair Enamelled Reel Weld Wire Roll FB

20pcs 0.1mm Copper Soldering Solder PPA Repair Enamelled Reel Weld Wire Roll FB

People who viewed this item also vieved

1pcs 500W Copper Electric Welding Solder Station Soldering Iron Tips Head

MG Chemicals 63/37 .032 DIA Solder (0.6 OZ) - No Clean

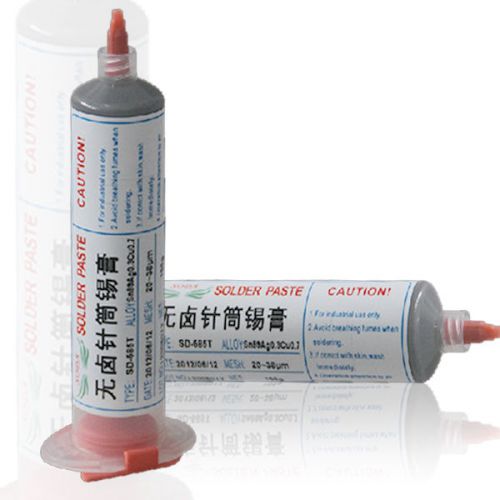

100g Sn42Bi58 SD-528T SMT Solder Paste Low temperature melting point 138 Degree

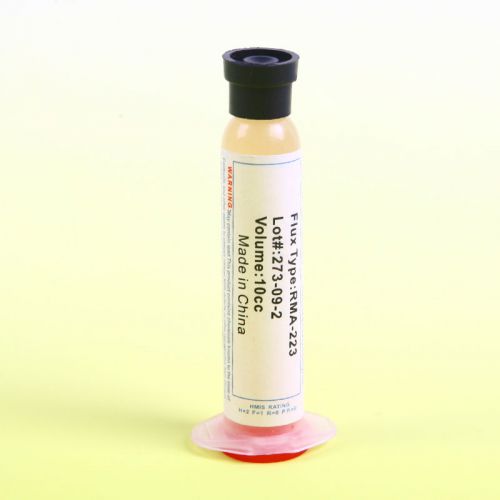

Industrial Solder Soldering Paste Flux Grease RMA223 10cc Welding Oil Pen

Pure Tin 100Sn Lead-Free Solder Bar Alpha Vaculoy 2.2 lbs

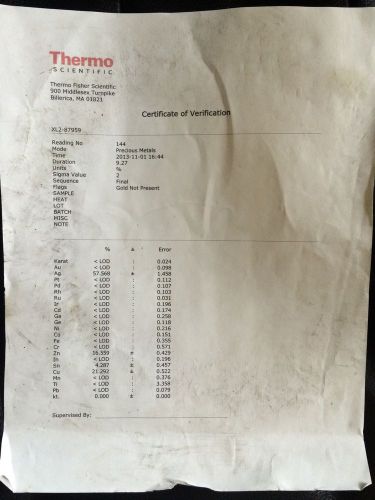

Silver brazing wire 36 troy ounces 57% silver .030 dia.

Metcal PTTC-608B 600°F Soldering Tweezer Tips - One pair

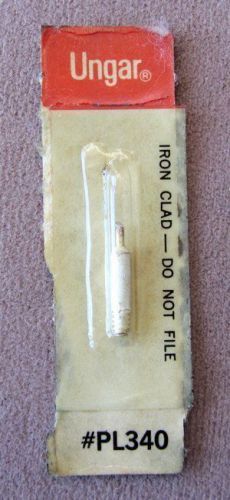

UNGAR PL340 Threaded Iron Clad Soldering Tip * New in Package

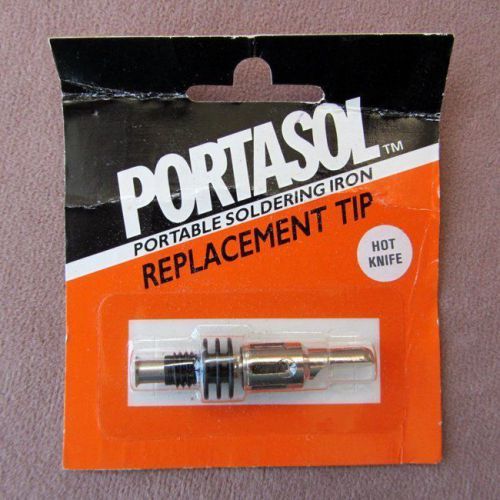

Portasol Replacement Tip HOT KNIFE for Portasol Weller Soldering Iron NEW

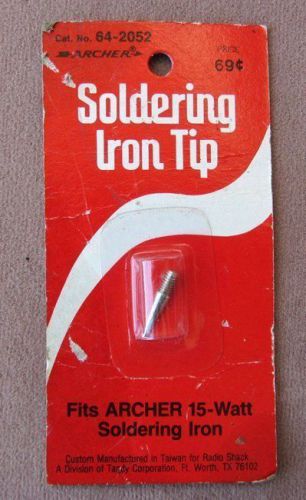

Archer Soldering Iron Tip 64-2052 *for 15 Watt Irons New in Package

PACE SOLDER TIPS 5 EA 1124-0035-P1 NEW

Hakko Solder Soldering T20-D16 Series Tip 1.6D for FX-8301 FX-8301

50pcs 22G Blue TT Liquid Dispenser Needles Plastic tapered tips

New Solder Tip Cleaning Wire and Holder

Radio Shack Digital Soldering Station (64-053)

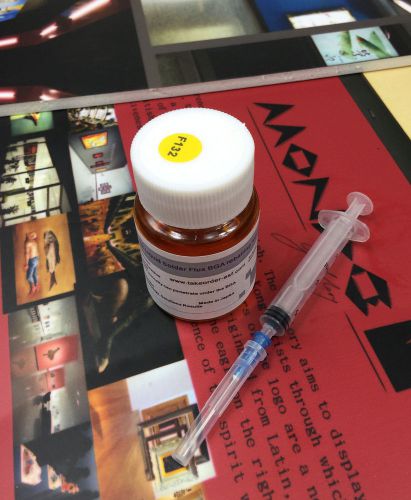

F132 Liquid soldering Rosin flux 50ml (Free Syringe) for reflow xbox gpu cpu

American Beauty Solder Pot (300)

Velleman VTSA Set of 6 Soldering Aid Tools

HEXACON SOLDERING IRON REPLACEMENT TIPS PTB-7, PTB-8

Hakko FR860 ESD Safe, Small Preheat Plate, Hot plate 120VAC, 60Hz SMT, BGA Rewrk

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies