US $14,995.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Equipment Type | Heat Transfer Presses |

Directions

Similar products from Stencil Printing Tools & Accessories

Promotion 1 Color 1 Station Screen Printing Press Signboard Printer Machine DIY

Screen Printing Starter Kit / Printing Press with Mesh Screens

Ink Jet Direct to Garment Printer

M&R Patriot 4668 American UV 2 bulb UV conveyor dryer

Brother GT-381 DTG tshirt printer

NuArc 26 1-K TABLE-TOP EXPOSURE UNIT/PLATE BURNER, 22.5 x 26.5 In. Inside Bead

Newman Tension Meter by newman stretch devices inc

Anatol Screen Printing Press -Industrial Grade - 6 Color / 6 Stations

M3 Newman Roller Frames 28X36 OD - USED Screen Printing Frame

Bending arts Avatar Mouse Pad Mat Mousepad Hot Gift

N7 Mass Logo Mouse Pad Mat Mousepad Hot Gift

Guinnesbeer Logo Mouse Pad Mat Mousepad Hot Gift

Super Car Wallpaper Mouse Pad Mat Mousepad Hot Gift

Metal Gear Solid 2 Sons of Liberty New Mouse Pad Mat Mousepad Hot Gift

Azuz Motherboad Extreme Mouse Pad Mat Mousepad Hot Gift

Zelda Game Logo Yellow Mouse Pad Mat Mousepad Hot Gift

Muse Band Siluet Mouse Pad Mat Mousepad Hot Gift

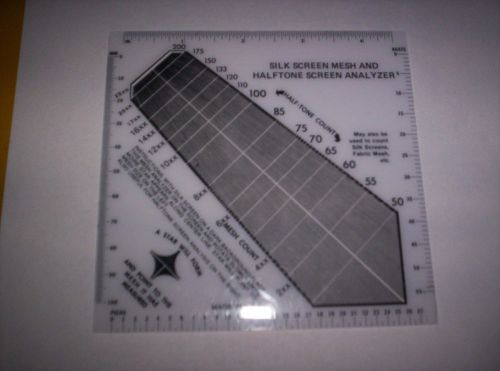

Silk Screen Mesh & Halftone Screen Analyzer Template.

Citra Paste Biodegradable Plastisol Screen Wash - Gallon BRAND NEW Screen print

People who viewed this item also vieved

Kingsley Hot Stamping Machine 23K Gold Foil Sheets Book Of 12 Sheets

Kingsley Hot Stamping Machine 18pt. Spacer Set

Kingsley Machine - ( 12 ) New 1" rolls - hot foil stamping Machine

Kingsley Machine Type Set Unknown Font Numbers

ENGRAVOGRAPH BRASS"SUPER STARS"PLATE 23/4" TALL

2- ENGRAVOGRAPH ENGRAVING MACHINE BRASS DESIGN PLATES 23/4" TALL

VYTEK STONE & TILE LASER ENGRAVING SYSTEM ETCHING MACHINE

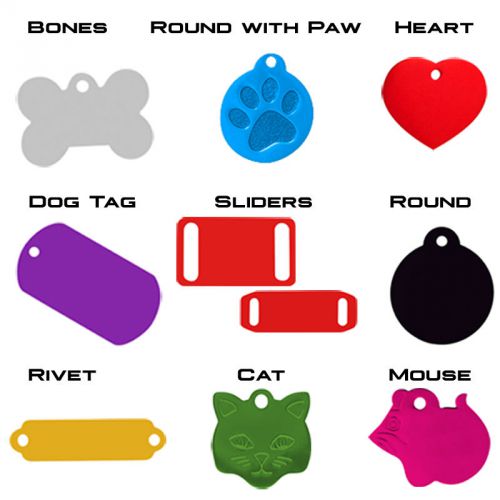

500 Assorted Pet Tags. Anodized aluminum. Ready to personalize.

Bakers Hat Custom Name Tag Badge ID Pin Magnet for Baker Bakery Pastry Chef

Art Palette Custom Name Tag Badge ID Pin Magnet for Artist Teacher Painter

Accounting Custom Name Tag Badge ID Pin Magnet for Bookkeeper Accountant Tax CPA

Design Your Own Custom Name Tag Badge ID Pin Magnet for Send Us Your Design

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies