US $520

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | ECO-WORTHY |

| Country/Region of Manufacture | China |

Directions

Similar products from Soldering Irons & Stations

Soldering Iron w/ Fine Electrical Rosin Core Solder - Circuitry Industrial Tool

Proskit 1PK-3616 Tool Kit for soldering

PLATO 30-300 DE-SOLDERING TIPS 10 PACK, SAME AS PACE 1121-0367

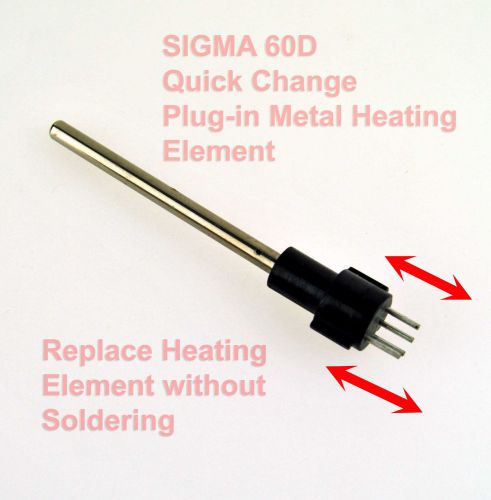

Two (2) Heating Elements Heaters for Sigma 60D Digital Soldering Station

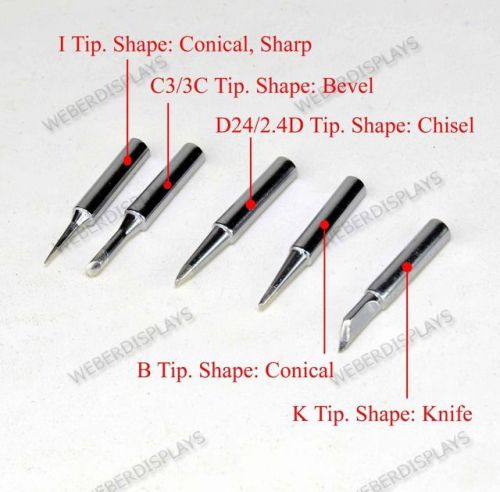

Five (5) Iron Tips for Soldering Station, 900M-T Type

WELLER 7881 ESD Safe Manual Desoldering Pump, US Authorized Distributor/ NEW

IDEAL 45-09 Stripmaster Wire Stripper 10 To 18 AWG, US Authorized Dealer NEW

Hakko 503-H-V22 220V/60W Heating Element (Total 10 pcs)

Weller D650 300/200 Watts, 120v Industrial Soldering Gun

American Beauty SS-8 3oz Solder Sucker Bulb, Free Shipping, New

Weller Cordless soldering iron kit WC100

New 10in1 Professional Butane Gas Torch Soldering Iron Tools Kit Welding Set

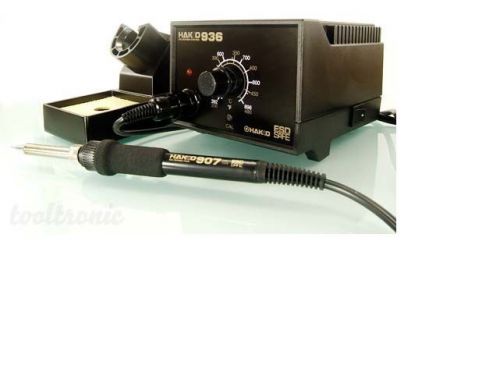

220V HAKKO 936 Soldering Station+907 soldering handle+A1321 heating element

Master Appliance 11799 Ultratane Butane 3-3/4-Ounce 106-Grams - Pack of 4

FA400 Portable Solder Smoke Absorber Air Filter Fume Extractor 110 / 220Volt

Circular Soldering Solder Iron Metal Stand Holder Bracket Base Welding Hand Tool

Weller WESD51 Digital Soldering Station w/Iron 50 Watt 350-850 Degree Adjustment

Heaterizer XL 3000 Heat Gun,110V, ORIGINAL FROM SPARKFUN

10pcs New Original Goot Weak BS-10 Acid Soldering Paste Flux Grease Paste 10g

People who viewed this item also vieved

40W Professional Soldering Iron Kit (Iron 40W+7' Wire+ 5' wick + pump)

40W Professional Soldering Iron Kit (Iron 40W + 7' Wire + 5' Wick)

40W Professional Soldering Iron Kit(Iron 40W+ Desoldering pump+15" wire+4" wick)

40W Professional Soldering Iron Kit (Solder Iron 40W+15" solder wire+ 4" wick)

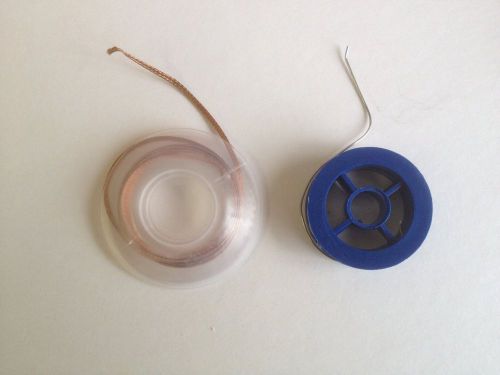

2' Soldering Wire 60/40 rosin core + 5' Solder wick 0.1"thick + Desoldering Pump

2' (2 Feet) Soldering Wire Rosin core (0.88mm) + (5 Feet) Solder wick 0.1" thick

2' (2 Feet) Soldering Wire Rosin core (0.88mm diameter)

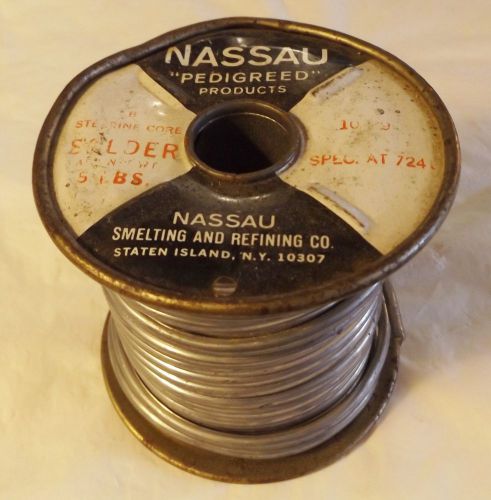

5 Pound Spool Stearine Solder Nassau Smelting Refinind Pedigree .165 dia

5 Pound Spool Stearine Solder 7241 B .167 dia

New Philmore HSW15 Solder Wick 0.08" (2mm) wide X 5 ft long

Oatey 95/5 95% Sn Tin 5% Sb Lead Free Solder 6.6 oz

Multicore Solder Wire MM01877- 1 roll

16 Ounces of SOLID WIRE LEAD FREE SOLDER - Litton / Kester Solder, .125 Dia.

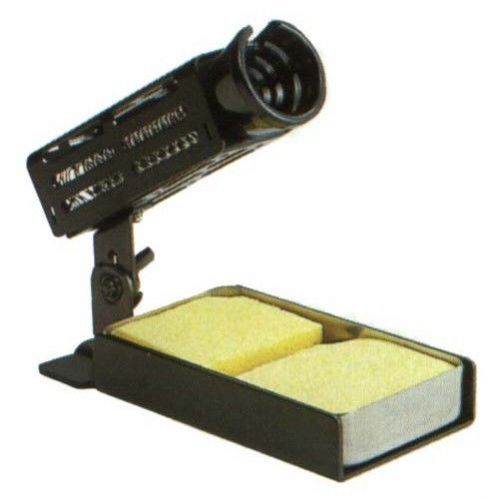

Goot ST-77 Soldering Iron Stand

Metcal Sta-Temp Desoldering System Replaceable Tip Cartridge STDC-703L

Blunt dispensing needles syringe needle tips 1" 200 pcs 14 Gauge luer lock

NEW! Weller Soldering Gun Iron SMOOTHING TIP #6140 w/ Fasten Nuts - D550 & 8250A

Weller LR-21 Soldering Iron 50W, 24V with Soldering Tip ET B

UNGAR (12) 1/8 THREAD-IN SOLDERING TIPS - PL332, PL340, 6951, 7154 - NOS.

Radio Shack Soldering Gun Copper Tips for Weller & Radio Shack Guns 64-237

PACE 1121-0625-P5 Pack of 4 Endura Thermo-Drive Conical Desolder Tip, 0.03mm

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies