US $1,250.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | XIANGHE |

| Country/Region of Manufacture | China | ||

| Model | TDP-5 | ||

| Aliases | Tablet Press/Pills Making/Particle Forming Machine |

Directions

Similar products from Other Medical Devices & Machines

Zeiss Portable ENT Microscope 200 mm Objective Lens Portable

Hewlett Packard M1351A Fetal Monitor Biomedically Checked

Midmark Upholstery Set For Midmark 641 New Pebble Gray

Hologic Sahara Clinical Bone Sonometer 04940 & Carrying case see photo's

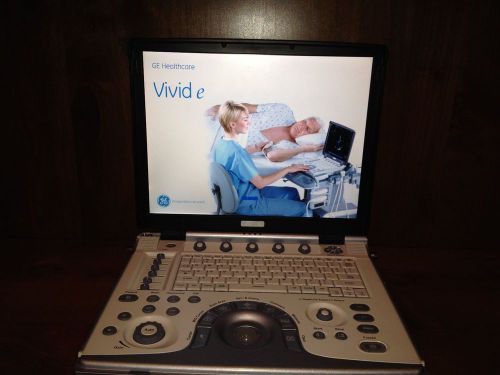

GE Vivid-e Echocardiogram Machine

OLYMPUS MA-995 Water Container Autoclave NEW IN BOX

Cincinnati Sub-Zero Connecting Hose Maxi-Therm Hyper-Hypothermia Blanket 286 NEW

Lot of 2x * GE MARQUETTE SOLAR 8000M REMOTE CONTROL NEW

Pulmonetic Systems LTV Ventilator AC Power Adapter and Cord (#11448)

Oxyhealth Solace 210 Hyperbaric Oxygen Chamber

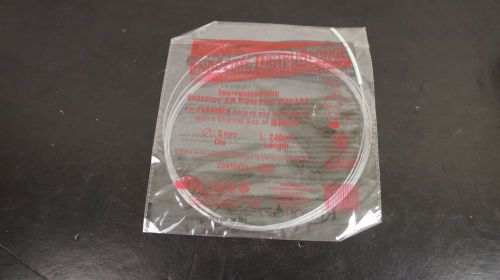

Ruhof 345ESS3F Enzymatic Channel Cleaning Sponge 3mm x 240cm ~ Lot of 10

Nellcor D25 Oxisensor II Adult Oxygen Sensor ~ Box of 23

6IN1 ULTRASONIC CAVITATION RADIO FREQUENCY SLIMMING RF CELLULITE LIPO LASER SPA

IPL Wrinkle Removal Skin Rejuvenation Permanent Intense Pulse Light Laser Device

Stryker Endoscopy AHTO Irrigation Pump 250-070-601 Power Cord WARRANTY

Philips Sonos 5500 M2424A Ultrasound System S3 Probe UP-890MD MD-835 #1

2005 GE 1.5T Open Breast Array Coil MRI 2246360 with WARRANTY

2005 GE Phased Array Torso Coil 1.5T MRI 2215261 with WARRANTY

Laerdal AED Trainer 2 with Battery Model 94005001 with WARRANTY

Stryker Endoscopy AHTO Irrigation Pump 250-070-601 with WARRANTY

People who viewed this item also vieved

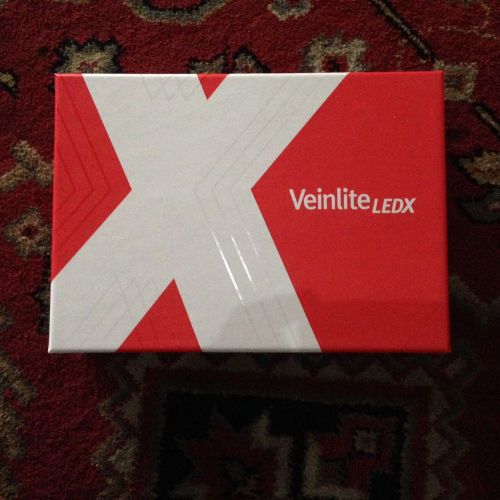

Veinlite LEDX Rechargeable Transilluminator Vein Finder

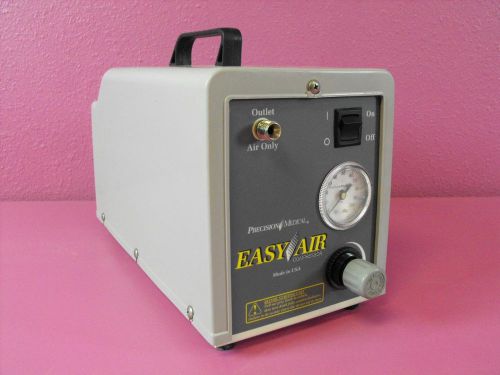

Precision Medical Easy Air PM15 Respiratory Compressor 15 lpm 80 psi ***NEW***

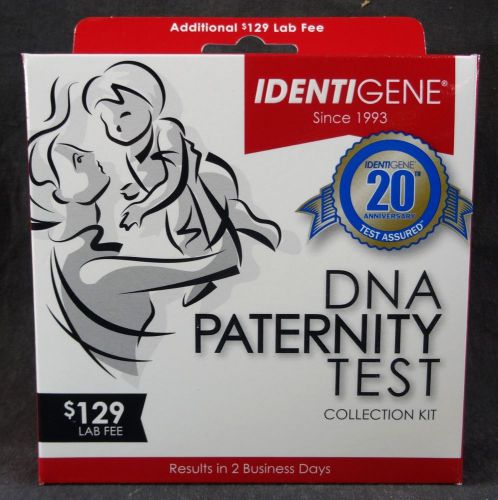

IdentiGene DNA Paternity Test Collection Kit (BOX OF 6)

Abbott Hospira Plum XL Micro Macro IV Infusion Pump Feeding Dosing

* CADD Prizm VIP Ambulatory Infusion Pump Model 6100

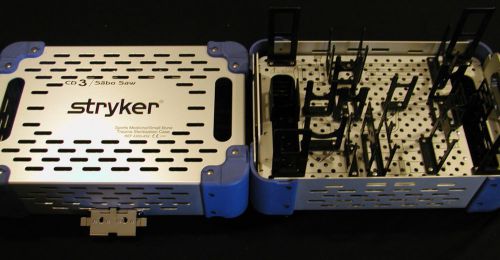

Stryker 4300-452 Trauma Sterilization Case

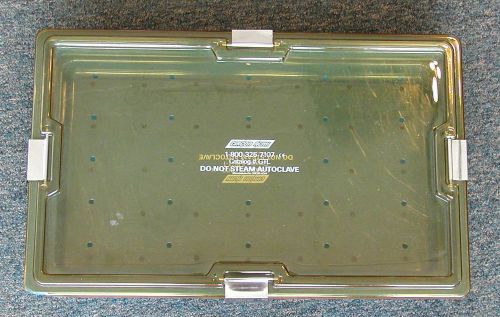

CIRCON ACMI Sterilization Tray

Sultan Chemists 2000 Pro-Sonic Ultrasonic Cleaner

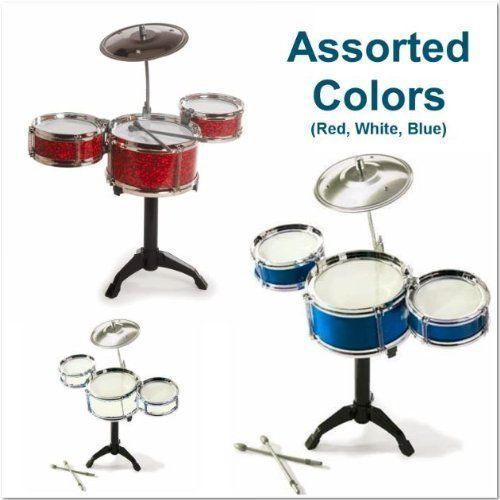

Desktop Drum Set - Random Color

ATOS PROVOX HME SYSTEM CASETTE XTRAFLOW 31 PCS New 2017

TWINBIRD 2-powered portable electronic proper temperature box

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies