US $250

Directions

Similar products from Other

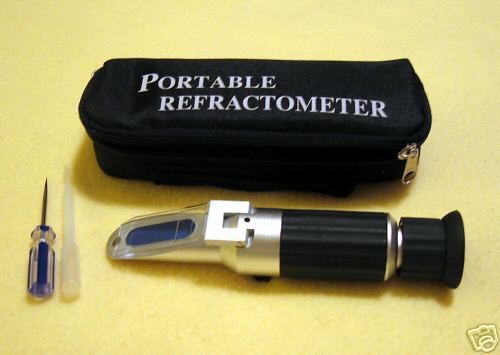

Westover RHB-32ATC Brix Refractometer CNC or sugars NEW

Klein Tie Wire Reel Lather Rebar Steel All Metal Construction

Aero-Motive 2-B Balancer - Lot of 2

Allen Manufacturing 1" Hex Key

Lot of 3 Spirit Boeing ID plates. Surplus find Aviation Aircraft Tool

Malco FBSN foamboard stapler with 300 staples

SNAP-ON TEC1FUA TorqoMeter Torque Wrench

Spiralcool Backing Pad SC F700-R 6.5" 6 1/2Diameter

Wood Handle Heavy Duty Roofing Shingle Ripping/Removing Shovel

Aircraft Hand Tools Tatco Rivet Squeezer Cleco Kwik Lok Wing Nut Fastners Burr o

Mountz TL0135 Torque Limiting Screwdriver 2-135cN.m

CORNWELL CCR-130 HEAVY DUTY AIR CHISEL HAMMER Blue Power

DEWALT #3 X 5-in Square Tip Screwdriver DWHT66423

Symmons Temptrol Seat Wrench Symmons Industries Misc. Plumbing Tools T-35A/B

DEWALT #1 X 4-in Square Tip Screwdriver DWHT66419

DEWALT 3/06-in X 3-in Standard Screwdriver DWHT66382

GREENLEE 30758 JUNIOR GRIP KIT

People who viewed this item also vieved

Strait-Line 65103 5lb Yellow Chalk

New Irwin Strait-Line Permanent Marking Chalk RED 8 Oz Bottle #64902

CH Hanson 70620 6" Locking C-Clamp w/pads

CH Hanson 72000 20" Locking Chain Clamp

Magnesiun Channel Bull Float 60" x 6" Broken-In #18418

Concrete Tamper 36" x 8" 17915

Klein Tools 1005 9-3/4" Wire Crimping/Cutting Tool

GW Elco Crimping Tool 06-7852-01 BR

PROOPS SWISS STYLE FINE MINI HAMMER WATCHMAKERS JEWELLERY MAKING REPAIRING

Prazi PR5000 Quickdraw Hammer Holster

2 Pc. Original Clamping Set 45619 Irwin Misc Pliers and Cutters 45619

Sg Top Trigger Utility Knife 10316 Warner Specialty Knives and Blades 10316

Komelon 81425 PowerBlade II 25-Foot Double-Sided Wide Hi-Vis Tape Measure, New

Komelon 81416 PowerBlade II 16-Foot Double-Sided Wide Hi-Vis Tape Measure, New

Ridgid 2A Heavy Duty Pipe Cutter Tool 1/8” to 2"

WACHS TC 4.5 ORBITAL TUBE / PIPE CUTTING MACHINE CUT OFF #1<-- GREAT SHAPE

K Tool New 2 1/4" Capacity 12" Long Aluminum Pipe Wrench with Steel Jaws

K Tool New 1 1/2" Capacity 24" Long Cast Iron Pipe Wrench with Red Enamel Finish

Vintage Benzomatic Torch Kit TX 2312 With Metal case Box

Lasertip Combo Screwdriver Set, Hex, 6 Pc 05007680003

Slotted Screwdriver, Cushion, 9.0mm, 6 In 05031436002

Pittsburgh cr-v 4 pc 3/8 drive impact extension set

NEW TAT 1/2" Drive Double End Impact Socket Sizes 3/4" & 13/16" LOT OF 12

Circle-Sizer Adjustment PEX Crimper

pittsburgh tools,9-1/2 in. Wire Crimping Tool 36411

2 THINLINE WRENCHES EASCO 7/8" x 3/4" PLUS CRAFTSMAN 9/16" x 1/2" FREE SHIP

ANTIQUE 1897 FORSYTH SPANNER WRENCH – Luthier / Machinist / Mechanist Tool

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies