US $48,860.49

| Condition | Used

:

An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “These units were professionally de-installed by Thermotron prior to removal. They are fully charged with refrigerant according to the service technician. The units are guaranteed to work.” |

Directions

Similar products from Environmental & Testing Chambers

Blue M POM-253C-1 Laboratory Oven

Lindberg / Blue M G01305A Gravity Oven

Thermodynamic Engineering TE Environmental Chamber Model 3132

CAMBION Bipolar Temperature Controller

HP 3488A Switch Control Unit Unloaded, Passes Self Tests

BLUE M AC-7602HAX ENVIRONMENTAL CHAMBER TEMP HUMIDITY lab oven

CINCINNATI SUB ZERO ENVIRONMENTAL TEST CHAMBER CTS-64-LN2 LIQUID NITROGEN COOLED

AES FD-202 Temperature Chamber (-65°C to +200°C) - 2 Cu.Ft.

AES SD-308 Temperature Chamber (-65°C to + 200°C) - 8 Cu.Ft.

G98306 Associated Environmental Systems SP 1101 Environmental Chamber

WEISS TECHNIK SB2/300/40 CLIMATIC ENVIROMENTAL TEST CHAMBER 4.8kVA 220V YR.1996

Marshall 2031 2000 Degree F High Temperature Test Furnace Instron Tensile Tester

Sigma Systems M100 Temperature Chamber w/ CC-3 Controller & Chart Recorder

846 1191-0407 Biotronette Mark III Environmental Chamber

LABCONCO MODEL 50350 CHEMICAL CARCINOGEN GLOVE BOX (OC86)

HumidityCabinet Healthcare,LifeScienceLabEquipment HeatingCoolingEnvironmental

Thermotron S-1.2V Minimax Enviornmental Chamber

Blue M 1004-3B-1 Dual Temperature System

Lunaire Chamber Oven Heating & Humidity - CE0932W-3 Photo - stability 27x33x60

United Environmental Chamber: UEC 3.5 – 600

People who viewed this item also vieved

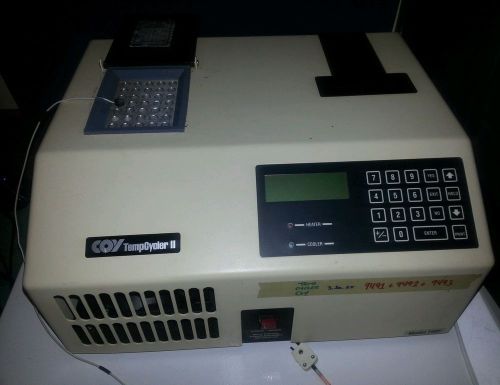

Coy Lab Products Temp Cycler Model #: 110P

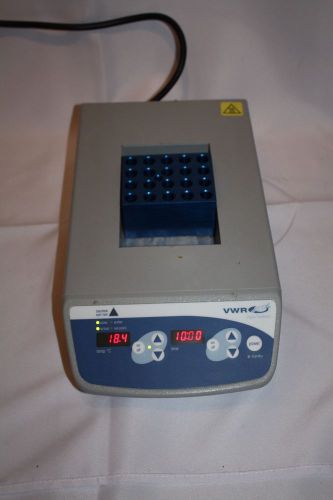

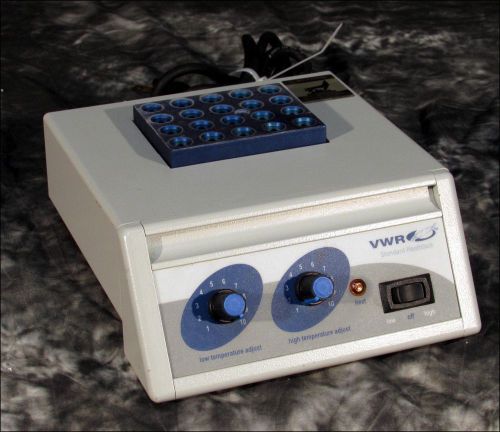

VWR Digital Heatblock w/ 1 Heat Block Heater Lab-Line

Shandon Lipshaw Laboratory Drier 218

Blue M Electric Model OV-8A Stabil-Therm Oven , 500W, 38C-200C, Stainless (B3)

tube furnace flange / Vacuum Sealing Assembly flange for Tube Furnace with Valve

1750 Grade MoSi2 Heating Element (30x250mm)

Williamson Viewtemp 2200 portable temperature monitor

Harvard Apparatus Temperature Controller

TAYLOR WHARTON 24K CROSCIENCE FREEZER

AUGAT 8136-PG132-60-2 WIRE BOARD GOLD PLATED NEVER USED

Bunsen Burner, Anderson & Forrester

Corning PC-220 4"x5" Ceramic 25°-550°C 1100RPM Magnetic Hotplate Stirrer PARTS

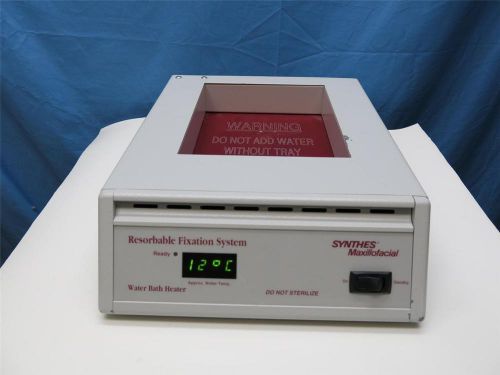

Synthes Maxillofacial Resorbable Fixation System Water Bath Heater

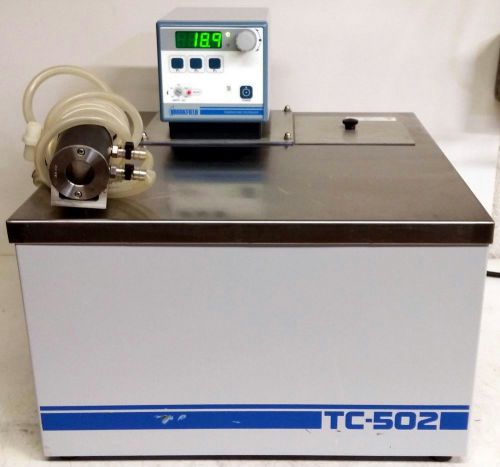

BROOKFIELD TC-502 REFRIGERATED HEATED CIRCULATING WATER BATH 115V TC-502D

Alsident System 75 Part Number 75-3590-3-7-5 Fume Extraction Arm &Ceiling Column

Forma Scientific 1106 Biological Safety Cabinet, Four Foot Fume Hood w/UV!

AL752LBLSSHV- 32" AccuCold by Summit Appliance Refrigerator- FREE SHIPPING

AL752LBLSSHH- 32" AccuCold by Summit Appliance Refrigerator- FREE SHIPPING

Have one to sell? Sell now Aspire Nautilus Tank - 1.8 ohm Subtank stainless ste

VWR 949030 STANDARD HEATBLOCK I (13259-030) WITH 20 HOLE ALUMINUM BLOCK

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies