US $1,499.00

| Condition | Used

:

An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “Exceptional Condition... Very Rare!!!” |

Directions

Similar products from Tools for Milling Machines

NEW OLD STOCK SANDVIK CORONMANT HYDRO GRIP CAT 50 TOOL HOLDER 392.45CG050 32 068

Sandvik Coromant 3" Carbide Insert Shell/Face Mill, R8 Arbor, hRK265.2-80M

Milling Machine Accessory - Right Angle Attachment R8 fits Bridgeport

NEW MORSE 1657-45 TOOLING JSO TAPER ADAPTER 1/4 IN STEEL TOOL HOLDER B448082

SANDVIK CAT 50 VARILOCK COOLANT INDUCER A394.45.0 50 63 130 0 (LOC1260B)

SCHAUBLIN CAT 40 ER 32 COLLET CHUCK 61 32 355 (LOC1261B)

SECO 1.25" COOLANT INDUCING END MILL SDH6 1.25R 2.48T W/ CAT 50 (LOC1260B)

VALENITE CAT 50 1.5" MILLING ARBOR 8.75" PROJECTION 711106553 (LOC1260B)

WALTER 3" FACE MILL 1" ARBOR F4042 UB 076 Z06 11 (LOC1258B)

WALTER CAT 50 ARBOR A100M U3 50 035 50 (LOC1260B)

HERTEL ENDMILL 1/2X1/2X1-1/2X6" 74453200

CINCINNATI #2 HORIZONTAL MILLING MACHINE ARBOR SUPPORT

Ingersoll 2" Hi-Pos Quad 0° Lead Extended Flute Shell Mill (25J3G-20022D1R01)

Niagra Roughing Milling Cutter 5 x 1 5/16 x 1 5/8 USED

Crest Cut Roughing End Mill 2 Flute .125 Radius 1" Shank 1 3/4" LOC

milling arbor,brown & sharp #9,sheldon milling,burke mill

3 5/8 x 1 1/2 x 2 1/2 Shell Mill Cutter

Crest Cut Roughing End Mill .250 Radius 4 Flute 1/2" Shank 1 1/2" LOC HSS

Staggered Tooth Milling Cutter 5 x 1 x 1/4 USED

Crest Cut Roughing End Mill 2 Flute 1" Shank 4" LOC HSS

People who viewed this item also vieved

Vintage~L.S. STARRETT~T HANDLE TAP WRENCH NO. 93C~LARGE CHUCK TOOL

Helicoil inserts 5/8-14 lot of 10 plus the tap and installation tool.

Rockwell Floor Drill Press Model 15-665

Adel Tool Co. Sheet Metal Nibbler for Soft Material Only, Not Over 18 GA .047 B1

Boyar Shultz 612 DeLuxe Hand Feed Surface Grinder with Walker Chuck

K.O. Lee S718-HA Hydraulic Surface Grinder with Coolant Pump & Tank

ASV HIGH SPEED HIGH FREQUENCY SPINDLE MOTOR FOR MILLING GRINDING ROUTER

ATLAS LATHE SOUTHBEND MACHINERYS HANDBOOK FOR THE ADVANCED MACHINST

ATLAS LATHE SOUTHBEND DOUBLE STEEL PULLEY

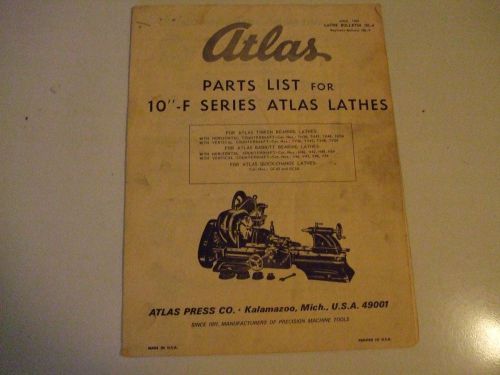

ATLAS LATHE PARTS AND ASSEMBLY INSTRUCTIONS 10 INCH LATHES

#ARJ ALPHIL 75 kVA Press-Type Spot Welder (New Approx. 1990's)

TAPCO 11151 BRAKE BUDDY SIDING ROLLER WITH HARD CASE

Sunnen LBA666 Precision Honing Machine AG-300 Gage Excellent Working Condition

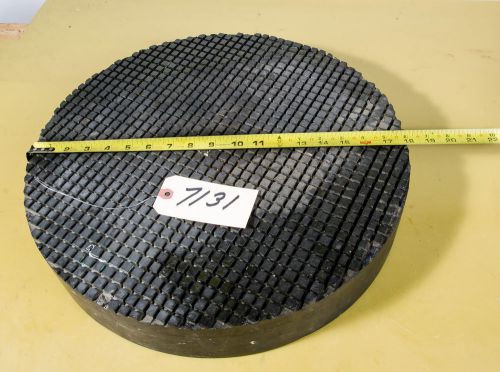

Lapping Plate; 18" Diameter (CTAM# 7131)

DAVENPORT / WINTERS THREAD ROLLS M4 X .07

National Acme chasers for Vers-O-Tools 1,650 x 10 NS LH 1 5/8 Dia 16792

DV43D: stainless wire EDM cut jig holder 95x23x12mm for Mitsubishi, Sodick

2 Germany Mann H34 1790/3 EDM Filter - Sodick

2 Mann H34 1290/1 Wire EDM Filter Makino, Mitsubishi, Fanuc 340mm x 300mm

13” x 18” Hyd-Mech Swiveling Head Horizontal Band Saw, Model S 20

DAITO (BETTER THAN AMADA!) MODEL GA 330 FULLY AUTOMATIC 14" HORIZONTAL BANDSAW

Vintage Atlas Clausing horizontal band saw Made in U.S.A model 4358

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies