US $1,799.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Tippmann |

| MPN | CL | ||

| Model | Clicker 1500 | ||

| Country/Region of Manufacture | United States |

Directions

Similar products from Other Processing Tools & Machinery

KleenTec Anti-Freeze Recycle Unit

Stainless Steel Mixing Skid Pharmaceutical

Komax 33 Wire Cut Strip Equipment

PASTERNACK PE6012 BNC MALE SHORTING DUST CAP (LOT OF 7)

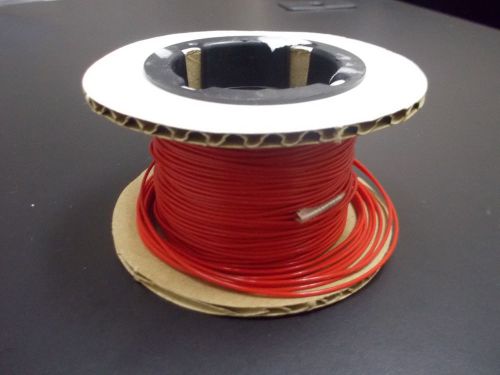

ICO RALLY SST-26 RED PTFE TEFLON TUBBING 26AWG,RED ROLL OF APPROX 100FT

PHI Heated Platen Press 10 x 12 Electric Platens

Spirol Mark V dual axis controller

MIKRO 1SH PULVERIZER 5 HP STAINLESS SS

Cherry Burrell Colton Rotary Tablet Press Model 216 389 W/CH Control 3 Ton Cap

Model ZM 1/44 Single Shaft Shredder Surplus slightly Used

REBUILT Sprout Waldron Andritz 501H Pellet Mill 100-150hp,NO feeder/conditioner

PATTON ELECTRONICS 2158/R COPPERLINK ETHERNET EXTENDER REMOTE UNIT FIRM rev D

# Honeywell Microswitch LSA3K New NOS Heavy Duty Limit Switch 600 vac 10 amps

* Honeywell Microswitch LSA3K New NOS Heavy Duty Limit Switch 600 vac 10 amps

Vacuum Furnace Vac Aero VAH 1220 HV2

1995 CATERPILLAR OLYMPIAN CD030 GENERATOR

Stainless Steel Tanker Trailer

Stokes model 43A Stainless Steel Oscillating Granulator

NEW GF SIGNET 161 546 346 BALL VALVE 1 1/2" DN40

People who viewed this item also vieved

Used MEC 48" X 138" with 20hp drive

Arrow Model 350, 1/15 HP Mixer Motor, 7 to 1 Ratio, 350 RPM Max, No Impeller

Eastern Process Mixer .25HP Clamp 115v Lightnin Style 72" L X 7" Propeller 316SS

LOT 2 NEW LIGHTNIN 130002316 CHUCK BODY D339109

Northfield 10" Air Chuck Serial No.10-1343

Dolan-Jenner Fiberoptic backlight QVMABLM

Dolan-Jenner Fiber-Lite DC 950H A Iris w/ filter

PECO Facet CC21 Series Coalescer Cartridge Part #CC-21CV For Model 21 Housings

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies