US $3,990.00

Directions

Similar products from Stepper Motor Driver Boards & Modules

CNC New 3 axis TB6560 Motor Driver Board 3.5A 36V For carving Engraving Machine

5pcs NEMA17 stepper motor 40mm 58 Oz-in 1.3A CNC stepping motor from RATTM MOTOR

Nema 23 stepper motors 425 oz in for cnc machine or 3d printer

Used Vexta Oriental UDK5107NW2 5Phase Stepper Driver Tested

NEAT 310-S Programmable Stepping Motor Controller with Cables

BALDOR MICROFLEX SERVO DRIVE 3A FMH2A03TR-EN23

NEW Schneider Electric Motion IM483 Microstepping Driver Micro Stepper/ Warranty

Browning A66 SUPER GRIPBELT V BELT( LOT OF 2)

Zebra LP2844 MAIN STEPPING Motor / M42SP-5 Part # 207230-001

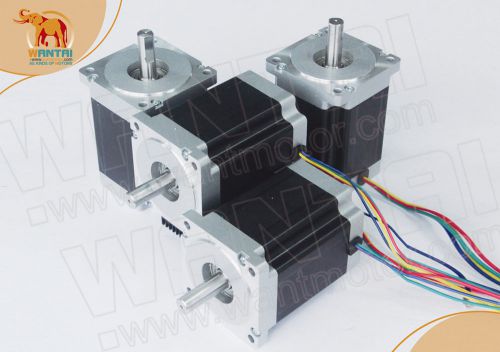

US Ship!Wantai 5PCS Nema23 Stepper Motor 57BYGH115-003 3A 425oz-in Single Shaft

USA Free! Wantai 4Axis Nema34 Stepper Motor Dual Shaft 1600oz 3.5A&Driver 7.8A

US Free!Wantai 3PCS Nema23 Stepper Motor 270oz-in 3A 4-Lead Bipolar Single Shaft

USA free!Wantai 3 Axis Motor Driver DQ542MA 4.2V 18-50V 128Micro For Nema23

Wantai 4 Axis Motor Driver DQ542MA 4.2V 18-50V 128Micro For Nema23 Stepper Motor

US Free! Wantai 4PCS Nema34 85BYGH450D-008 Stepper Motor 99mm 5.6A 1090oz-in

US Free! Wantai 1PC Nema42 Stepper Motor 110BYGH150-001 150mm 3256oz-in 6.0A

US Free! Wantai Nema 42 Stepper Motor Driver DQ2722MA 110-230VAC 2Phase

US Free! Wantai 3Axis Stepper Motor Nema23 57BYGH627 270oz-in 3A 4-Wire &Driver

Ship From USA! Wantai 10PCS Nema17 Stepper Motor 42BYGHW804 4800g.cm 48mm 1.2A

People who viewed this item also vieved

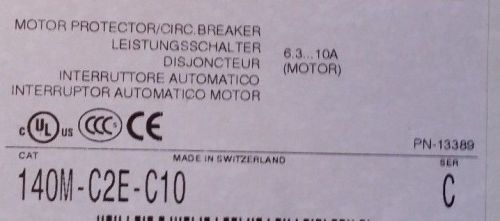

Allen Bradley 140M-C2E-C10 Lot of 2

MATSUSHITA GREEN POWER TYPE FC-25 BMF6-25 AC MAGNETIC CONTACTOR

Siemens 52BAK Series G Used Lot Of Two

Allen Bradley 100-C60D10 Contactor, Series B - NEW in the Box!

NEW EATON CONTACTOR CAT.# XTCE009B10C /3P FVNR 9A FRAME B 1NO 415/50 480/60 COIL

UNUSED NOS Cutler Hammer C65FNF275 Contactor 75 Amp 240 Volt 2 Pole

Allen Bradley Bulletin 104-C09D22 Reversing Contactor, ser A - NEW in the Box!

BOSTON GEAR RATIOPAX DC MOTOR CONTROL

NEW IN BOX APPLETON VPGU-1 ALUMINUM GUARD

New 12x Intermec 1-040960-11 Stepper Motor| Compatible with PM4i| Test Equipment

NEW SIEMENS CONTACTOR SIZE 3 MODEL 3TF4722-1AK61 80 AMP 600 VAC 120V COIL

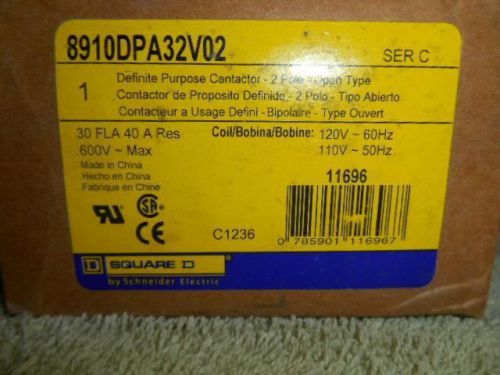

Square D Definite Contactor 8910DPA32V02

Clutch/Brake Controller Dynatec 2100 214215

Siemens 3RN10111CK00 New 3RN1011-1CK00 Thermistor

FLENDER VARITEX 2E2R-20400-007 frequency inverter 0.75KW

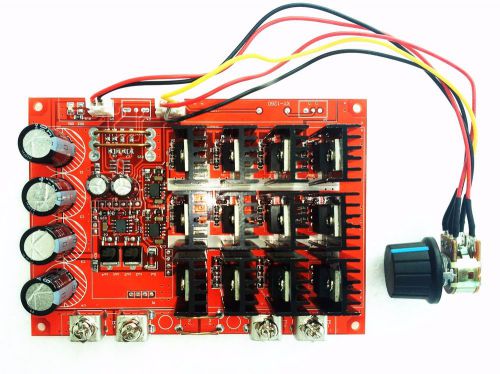

High-Quality 10-50V 40A DC Motor Speed Control PWM HHO RC Controller 12V 24V 48V

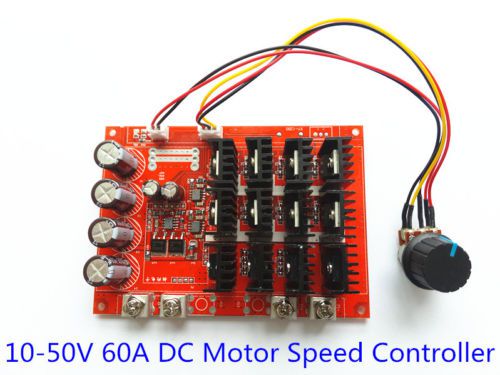

NEW 10-50V 60A DC Motor Speed Control PWM HHO RC Controller 12V 24V 48V 3000W

SOUTHTERN INDUSTRIAL CONTROLS MOTOR SPEED CONTROL DC DRIVE 1 HP 115 VAC 90 VDC

Control Techniques EMERSON SP 4401

Control Techniques EMERSON SP2403

12V 24V 48V 3000W MAX 10-50V 60A DC Motor Speed Control PWM HHO RC Controller

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies