US $14000

Directions

Similar products from Muffle Furnaces & Thermocouples

CM High Temperature Box Furnace Controller * 1200 Series * 208 V * Tested

THERMOLYNE 79300 100°C to 1200°C Programmable 12" Split Tube Furnace F79325

DS Fibertech Tube Furnace Heat Element for External Torch 00262916, 5 3/4" Long

Lindberg Hevi-Duty Tube Furnace 24"X2" 115-230V 54241 1010C MAX

Fisher Scientific Isotemp Muffle Furnace 186A

TLD 168 Annealing Furnace 120 VAC, Setpoints 80,100,400 Celsius - 2,000F Max

LINDBERG FURNACE 51435 208/240V MAX 1800C

Barnstead Thermolyne 304000 FURNACE 208V VERY NICE

Thermo Scientific™ Jewett™ Dual-Temperature Refrigerator/Freezers Model PRF17-1B

Split tube furnace, Horizontal, 34000 W, 3 zone, 2200 deg F, TSP-11.5 Thermcraft

CM High Temperature Box Furnace Controller * Model #1712FLGS * 480 V * Tested

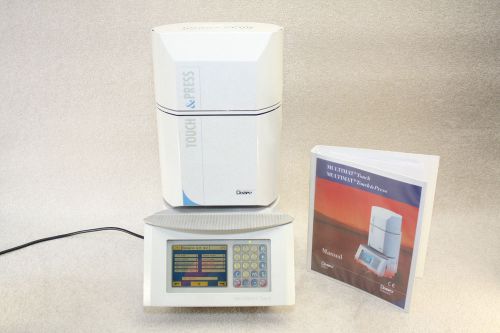

Dentsply Multimat Touch & Press - Dental Lab Furnace / Press

Barnstead Thermolyne 6000 F6010 Benchtop Furnace

THERMO SCIENTIFIC LINDBERG/BLUE M BF51542C LAB BOX FURNACE 6.2kW 1200C PARTS

Furnace Controller Stuller Brand Jewelers Equipment used working condition

U type silicon carbide heating elements 270x52x12mm(LXWXD)

Mellen Clam Shell Design Tube Furnace w/ Micricon 823 Controls

Lindberg/ Blue M 1200 degree C Lab Oven/ Box Furnace With Controller. Excellent

CARBOLITE SHEFFIELD FURNACE - AAR 3748

Lindberg Hevi-Duty 51442 Series Box (Muffle) Tube Furnace w/ 59344 Controller

People who viewed this item also vieved

Corning PC353 stirrer mixer magnetic model PC-353 lab laboratory magnet ln

Gas Bunsen Burner Lab & Life Science Lab Equipment Heating LPG Burners

3050 CTI Cryogenics 8043074 Stainless Steel Braid Hose

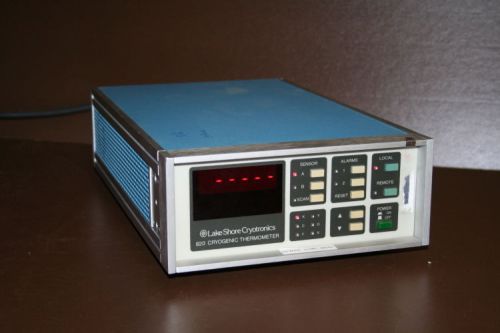

Cryogenic thermometer controller 820 Lakeshore Cryotronics Repair/Parts

Environmental Specialties Inc. Modular Walk-In Chamber

Envirotronics Enviromental Chamber Model EA 26-1-1-HAF-W/C

Thermopol Solid State Refrigerator DLA-50T Biomedical Military specs

SOXHLET HEATING MENTAL Lab Equipment and Instruments Manufacturer & Exporter 3

Glas-Col Laboratory 500mL Soft Heating Mantle w/cord

Baker SC4TXSB SterilChemGard 4 Foot Class II Type B2 Total Exhaust Cabinet

Misonix Mystaire 2450 Ductless Fume Enclosure With Hepa Filter

Hoben International Oven HDG Bakeout Furnace Lost Wax Casting No Coils

VWR, SHEL LAB Convection Oven Model 1370GM, Max Temp: 240C, Capacity: 5 cu. ft.

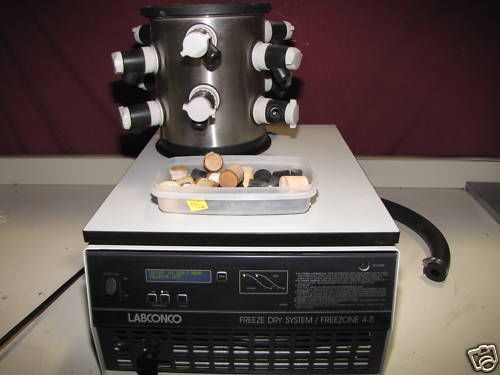

Labconco Freezone 4.5 Freeze Dry System

**New** Lytron MCS Modular Cooling System LCS60G01M02

HM Digital EC-3 EC Conductivity Meter / Tester / Thermometer, Conductometer

YELLOW SPRINGS 43TS YSI 40-150F 0-65C TELE-THERMOMETER B336593

Fisher Scientific Isotemp Refrigerated Recirculator Model 9000

MGW Lauda Recirculator Model K4R

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies