US $15000

Directions

Similar products from Cachets & Wafers

Watlow foreline heater AMAT p/n # 1410-00182 1 pcs 63v 104w

Watlow foreline heater AMAT p/n # 1410-00183 1pc 66v 130w

MKS foreline heater AMAT p/n # 1410-00834 1 pcs 208v 64w 0.31A 50/60 Hz

Amat 0190-70066 Fantray 300Cfm 19"X1.75"X8" 115Vac Replo

Fluoroware E124-60 Robox 6" Ultra Pack Silicon Wafer Shipping Container No Lock

Ultron Systems UH130 Die-Matrix Expander - Exc Cond

MDC QUIETCHUCK HOT CHUCK DC CONTROLLER MODEL 490, Serial #'s 337 and 310

K&S Kulicke and Soffa Model 750 WAFER SCRIBER

American Tool & Manufacturing Wafer Spinning Roundness Jig 571941-XA

Allied Signal ElectronCure 30 Power Distribution Unit

Parker Compumotor Control Board PCB 61-006084-02Y PCA 71-006085-02

Trion Oracle Plasma Etch Deposition with Turbo Pump Varian Turbo-V 300

LFE Corporation ICP Barrel Type Plasma Chrome Etch System (PFS/PCrE/PDS-501)

Applied Magnetics Semiconductor Wafer Variable Speed Spin Dryer Stainless Steel

Systems Chemistry/Fluoroware Chemical Control Valves in Sealed Enclosure 201-32

Systems Chemistry Valve Manifold Box VMB F/T 1POU

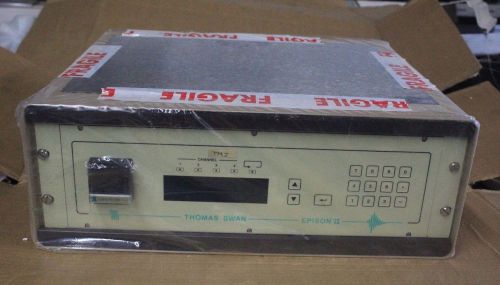

THOMAS SWAN EPISON 2 GAS FLOW ANALYZER MOCVD / IN CRATE !!! NO RESERVE !!!

ULTRA-FLO ULTRAFLO MASS FLOW CONTROLLER-UC2-21SO2 N2 100SCCM -b

People who viewed this item also vieved

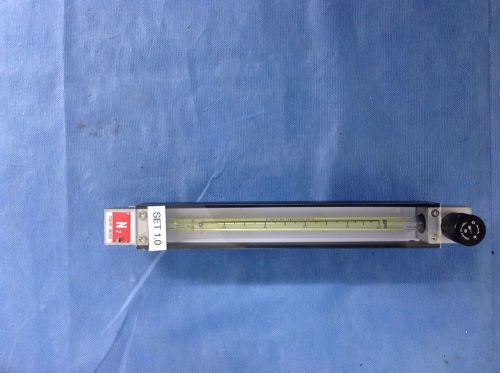

TOKYO KEISO N2 GAS FLOWMETER , 1-110 PSI/MIN, F01-280114

MKS Instruments DLT2A223163R210 Flow Ratio Controller

MKS Instruments DLT2A223163AA Flow Ratio Controller

MKS Instruments DLT2A2-30952 Flow Ratio Controller

VAT PM-5 641PM-16PL-002/257 Adaptive Pressure Controller U

Siemens S7-200 6ES7214-IAD22-0XB0 CPU U

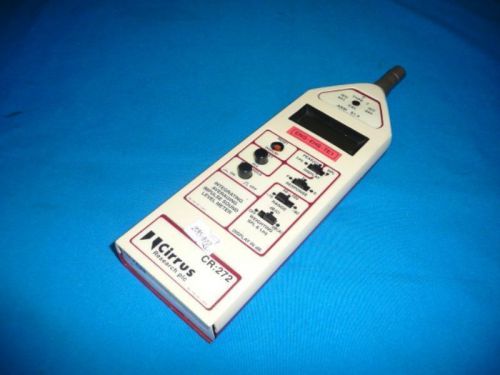

Cirrus CR: 272 Sound Level Meter U

Sanyo Denki Stepping Motor RM5685D

CASCADE Microtech Microprobe ABR0600059 and ABR0600062

3051 Applied Materials 0150-76646 002 Centura EMO Controller Interconnect Cable

CASCADE MICROTECH / ALESSI DCM100 XYZ PROBE POSITIONER / MISSING COLLET #7

CASCADE MICROTECH / ALESSI DCM100 XYZ PROBE POSITIONER / MISSING COLLET #6

VAT 331612 CABLE ASSEMBLY / ADAPTER CABLE

AMAT PCB ASSY, ANALOG INPUT for P5000 / 0100-09054

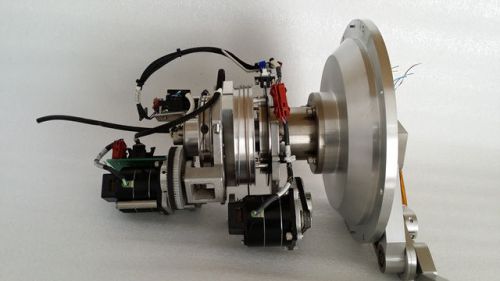

AMAT wASSY ROBOT DRIVE for P5000 / 0010-76000

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies