US $8,999.99

| Condition: |

Used: An item that has been used previously. The item may have some signs of cosmetic wear, but is fully

operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

...

|

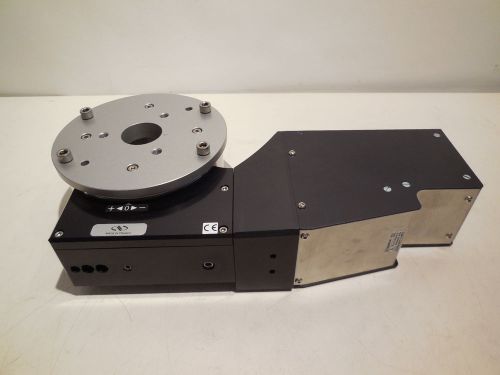

Brand | Unitek |

| Model | B-2100-A |

Directions

Similar products from Testing & Assembly Equipment

Hitachi S-5000H FESEM instrument

MICROMANIPULATOR 525 4 AXIS PROBE POSITIONER MANIPULATOR

OMAX 10X-80X Boom Stand Zoom Binocular Stereo Inspection Microscope

5X-80X Boom Stand ZOOM Stereo Microscope with 1.3MP Camera +54 LED Light

OMAX Boom Stand 5X-80X Binocular Zoom Stereo Microscope with 54 LED Light

OMAX 5X-80X Binocular Zoom Stereo Microscope with Boom Stand

T-Tech AMC2500 Quick Circuit Controller for Milling Router Table

Newport Linear Motorized Stage with Motor Model: UE511CC with 30 day warranty

Newport Rotary Stage with Motor Model: UE511S with 30 day warranty

Novellus Speed Load Lock Robot 02-053993-01

Axcelis Isolation Valve 031011

Yamatake Temp Controller SDC20 C205GA00601

EDWARDS ISOLATION VALVE PV40PKS B

VAT VALVE 349434 / 0003 A-838182

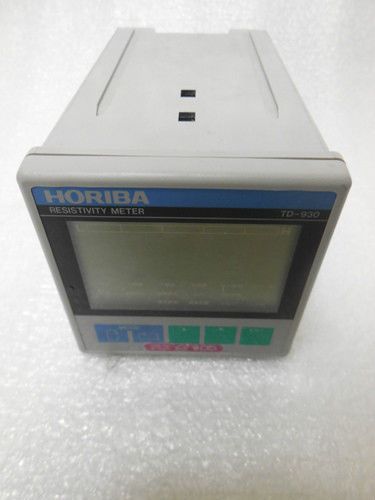

HORIBA RESISTIVITY METER TD-930

VARIAN PNEUMATIC ANGLE VALVE NW-40-A/O

PANASONIC AC SERVO MOTOR MSMA0 12A1E+MSNA0 12A37

People who viewed this item also vieved

Cyonics JDS Uniphase 2212-4SLMD Industrial Lab Argon Laser Head Module PARTS

Horiba STEC LF-A40M-A-EVD 7g/min TEOS Flow Control NEW

Bule Jay M1000 LPCVD, BJM1000, TM Module, EFEM Module, PM Module, MCR, MPB

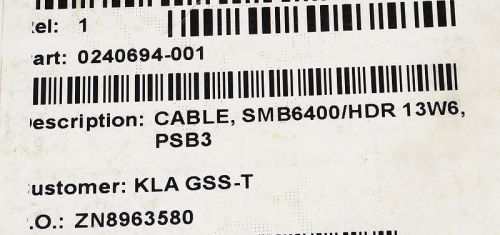

KLA Tencor CABLE, SMB6400/HDR 13W6 PSB3

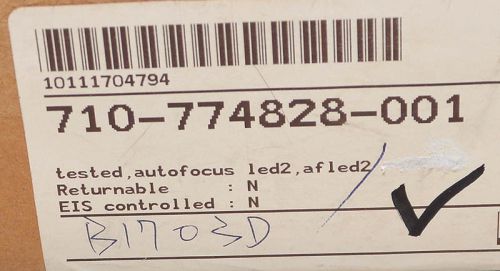

KLA Tencor tested, autofocus led2 afled2 710-774828-001

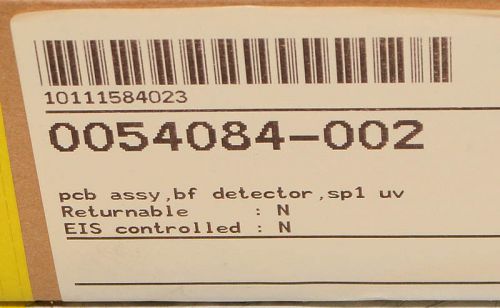

KLA Tencor pcb assy, bf detector, sp1 uv

KLA Tencor FRU ATTENUATOR ASSY HALFWAVE EC SP2 NEW SEALED 0253452-001 SURFSCAN

KLA Tencor fru, mirror, m1/m2, normal, intel, sp2+ 0220037-003 NEW SEALED

Blue M CC-13-I-P-G Large Horizontal Airflow Mechanical Convection Oven

Aerofeed Desiccator Storage Cabinet with Slide-Out Shelves

BRANSON L3200SS CASSETTE TO CASSETTE ASHER

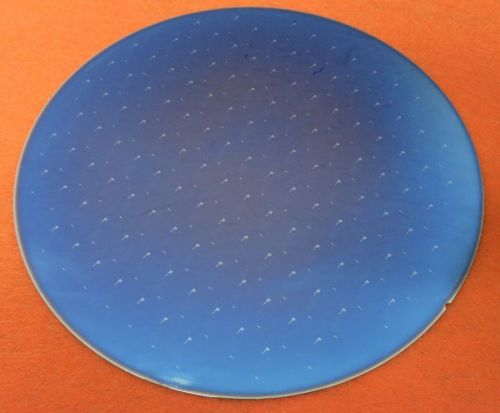

8" 200mm Silicon Wafer for Art Projects Pattern on front, blank back #40

![[LOT 25]12" 300mm Silicon Wafer Shiny Front and Back w/ GSW300 Box #17](/_content/items/images/89/4369689/001.jpg)

[LOT 25]12" 300mm Silicon Wafer Shiny Front and Back w/ GSW300 Box #17

![[LOT 25]8" 200mm Silicon Wafer for Art Projects Blank Shiny Front Read Below #12](/_content/items/images/90/4369690/001.jpg)

[LOT 25]8" 200mm Silicon Wafer for Art Projects Blank Shiny Front Read Below #12

![[LOT 3]8" 200mm Silicon Wafer for Art Projects Cool Pattern Blank Back #49](/_content/items/images/91/4369691/001.jpg)

[LOT 3]8" 200mm Silicon Wafer for Art Projects Cool Pattern Blank Back #49

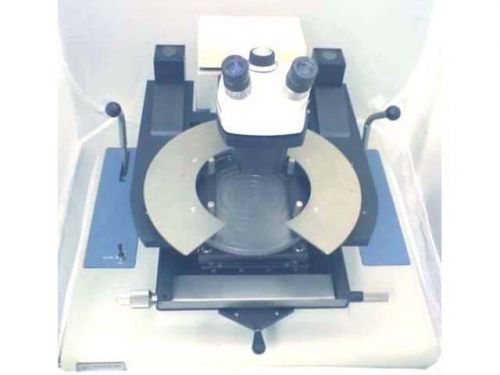

ULTRACISION 860 Manual Probe Station (2 MANIPULATORS INCLUDED)

TELEDYNE TAC SCT AUTO SUBSTRATE CONTINUITY TESTER

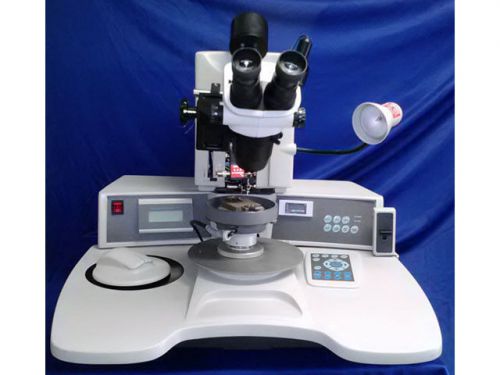

K&S 4524AD BALL BONDER (guaranteed to bond your product)

EMPAK Ultrapak 150 mm wafer cassette and box PH9150 NOS

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies