US $280

Directions

Similar products from Others Mig Welding Equipment & Tools

Metco 10E Thermal Flame Spray Metalizing Gun with Manuals

SAMSUNG WASHER DOOR Lock DC34-00025A

Lincoln Electric Cool-Arc 20 Water Cooler.

OEM THERMAL DYNAMICS 8-3233 GAS DISTRIBUTOR PCH20

Industrial Work Table Metalworking Welding Fabrication Table STEEL

Metco Type N Metallizing Thermal Spray Gun

Miller Trailblazer Running Gear

TWECO GAS DIFFUSERS 51 - QTY/2

1 QTY DAVIS Flange, Stainless Steel, 1/2" Bolt

QC Brand 25" Water Hose, Q45V08

2 ROTO WELDING CABLE QUICK DISCONNECT PC-62 M COPPER BRASS NEW

Miller Welding Cable #1 (2) 25ft Runs

Tweco Weldskill 2 Male Connectors WDC50P

BRAND NEW HOBART 50 A, 230 VOLT CROWFOOT-TYPE MALE PLUG WELDING WELDER 770025

Lincoln SA200 Welding Machine, Part, Front fan belt pulley

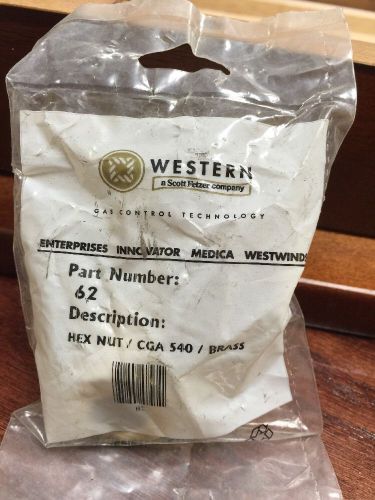

Western Enterprises - HEX Nut CGA-540 (Western) CO-2 Nut CGA - 540 PN 62 Brass

TREGASKISS 404-3 RETAINING HEAD - QTY 2

Thermoweld MOLD # M-232 , CC2 SIZE 2/0 STR TO RUN & TAP CART 90

TREGASKISS 404-30 RETAINING HEAD - QTY 2

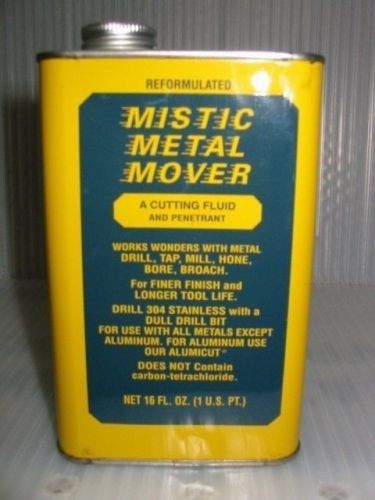

MISTIC METAL MOVER- CUTTING FLUID & PENETRANT - 1PT

People who viewed this item also vieved

Miller 000068 Mig Welding Contact Tip .035" Pkg = 10

Miller 135430 Tip,Contact .035/53 Wire. Pkg = 10

Bernard D-1 Cfire Diffuser Large Nzl Pkg=10

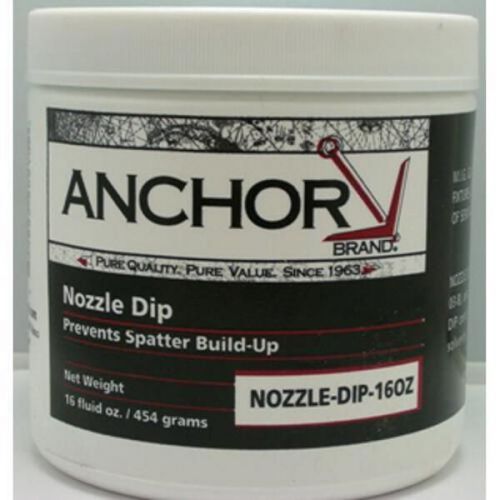

Anchor Brand Nozzle Dip For Mig Gun Nozzles And Tips

Lincoln Electric KP35-40-15 Liner For .023" To .035" Wire

2008 Miller XMT 456 CC/CV 450 amp w/ 60M feeder Sharp Arc pulse mig 64M SharpArc

RADNOR 250M153035 250 AMP MIG GUN 15' MIL STYLE CONNECTOR

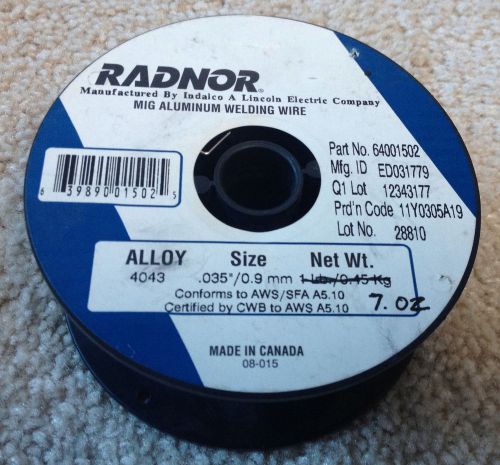

Radnor ER4043 Alum Alloy MIG Welding Wire .035" / 0.9mm 7oz Roll

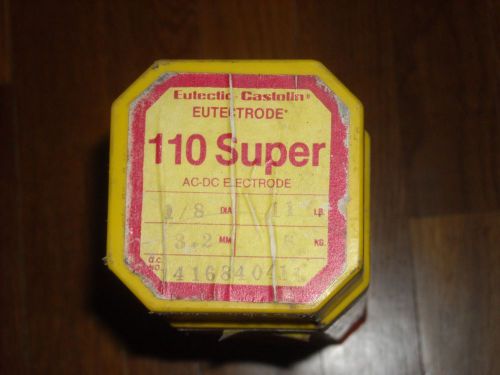

EUTECTIC + CASTOLIN WELDING ELECTRODES/ 110 Super AC/DC 1/8 inch

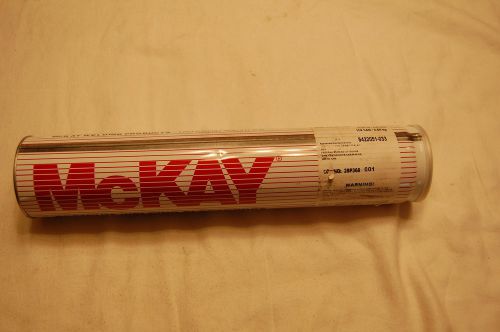

McKay E7018 XLM Welding Electrodes 5/32" 10 Pounds

Gas Flame Lighter Welding Blowtorch Torch Picnic Heating BBQ Rods Flux Paste

aluminum welding wire 4043 mig .035 diameter 13 pound spools made in USA

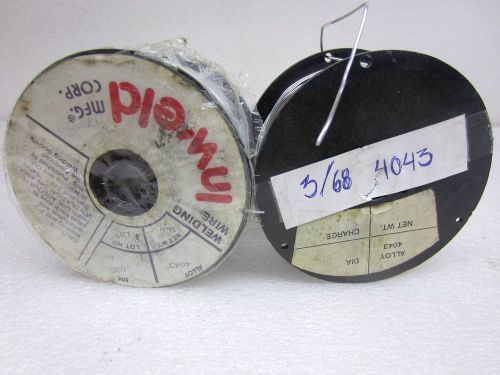

2 Spools Aluminum Mig Welding Wire .035 4043, Inweld Al ..........R206.14.10

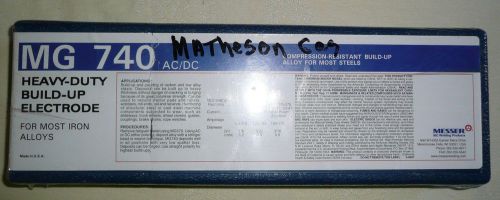

MG 740 AC/DC HEAVY DUTY BUILD UP ELECTRODE-NEW

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies