US $175.00

| Condition: |

Used: An item that has been used previously. The item may have some signs of cosmetic wear, but is fully

operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

...

|

Brand | Unbranded/Generic |

| Country/Region of Manufacture | Unknown | ||

| Model | T&O |

Directions

Similar products from Other Cutting Equipment & Expendables

MITSUBISHI 1-3/4" DIAMETER INDEXABLE 3-STATION END MILL With 1-1/4" SHANK

FOUR Assorted Countersinks /Cutters Sold As Is

Cleveland Microbores Lot of 6 microbores

MOSTLY SMALL SIZED AVIATION TYPE TAPS 10 TOTAL 1 PRICE ---reduced price

Machinist Lathe inner bore burnisher Dayton chucks new bearings & bearing collar

Nine vintage Reed Mfg. Company square Thread Cutting Die Machinist pipe antique

Four Machinist end mill holders varios tool diameters

Machinist Mitutoyo Starret micrometer micrometer Brown & Sharpe in wooden holder

Three Magnetic Base Machinist Tool Indicator with working Starrett gauge

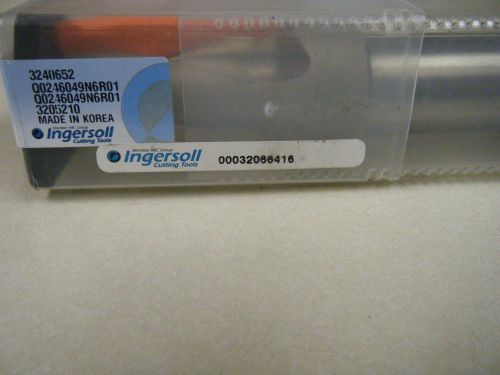

Ingersoll .962 Indexable Drill 3240652

Georg Fischer RA21 Orbital Electric Pipe Saw 1/4" - 2" Tube Bevel Cutter Tool GF

U.S.A.! SET OF CLEVELAND HIGH SPEED COUNTERBORES .186" - .343" BORE DIA.

Carbide Tipped Radius Lathe Cutting Bit

Vermont Tap Carbide 2" - 4,1\2 5 Flute Plug

SUMITOMO TOOL HOLDER MCKNR164D FOR MACHINING WITH INSERTS

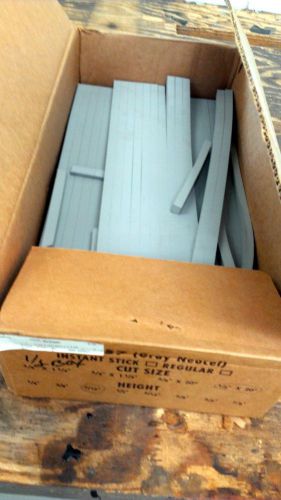

Gray closed cell steel rule dies Rotary cutting dies crease rubber

Bobst Screws , Centering blocks , cutting dies steel rule

Black Open cell sponge rubber 7/16" x 1/2 x 1 1/4" for steel rule dies

People who viewed this item also vieved

COMOL Staggered Teeth side milling cutter 5"x3/4"x1.1/4" (sn 101)

Staggered Teeth side milling cutter 80X8 (sn 136)

WELDON 1/2" inch, Shank Drill, HS, 4 Flute, 4" inches long, USA

LOT OF 2 NEW 5/16" END MILLS , 2 FLUTE , 3/8" SHANK , PUTNAM TOOL

NICE PAIR OF HSS L&I 2MT REAMERS .6290

LOT OF 5 CARBIDE TIPPED ALLIANCE EXTRA LENGTH REAMERS 1/2"

Roper Whitney No 7 punch and die set 7/32" round

Punch Die Set .500" 1.753" Rectangle Shape Diacro 906-212B Shank 1.250"

LENOX QXP 11'6" (138")X1"X.035"X3/4 VP VR NEW!

LENOX QXP 13'6"(162")X1-1/4"X.042"X3/4 VP VR NEW !

DUMONT Minute Man #22214 7/16-D Broach

DUMONT Minute Man Broach 7/8-F HS

Carbide Burr Set of 5 - Choice of One Set of Five Different Sets

Drillco 7000N Series Magnum Solid Carbide Miniature Bur, Single Cut, Inverted

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies