US $2,507.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

UPC | 45635059085 |

Directions

Similar products from Espresso Machines & Spare Parts

SCHAERER MACHINE PROGRAM EPROM V2.12 P/N 22817

Rancilio Silva Espresso Machine Coffee Bean Grinder Restaurants Supplies Home

La Cimbali M2 Bar System Espresso/Cappuccino Machine

La San Marco Keypad for all 95 models E

Portable Outdoor Butane Gas Burner for Hario Syphon Coffee TCA-2 TCA-3 TCA-5

Nuova Simonelli MAC Espresso Coffee Maker Machine 2 Group

Nuova Simonelli Aurelia 3 Group Commercial Espresso Machine - See Demo Video!!!

Espressa Leonarda Italian-made Espresso Machine

astoria, AL /2N Expresso Machine (2 Head)

La Vittoria Two Group Espresso Coffee Machine

Flow Meter PH12 for NUOVA SIMONELLI Part 04900027

Nuova Simonelli Master Boiler Heating Element 1800W part 14100029

Steam Pipe assembly for NUOVA SIMONELLI Part 9805007

Lot of 12 New Nuova Simonelli Right Hand Steam Valve Handle Lever part 05000040

Pressostat Pressure Switch 30 AMP for Nuova Simonelli part 09200006

Double Scale Gauge for Nuova Simonelli part 09100003

3-way Electro Valve for Nuova Simonelli part 04100027 with Parker ZB09 coil

Master Heating Element 14W for Nuova Simonelli part 14100035

Master Delivery Electro Valve for Nouva Simonelli part 04100028 with Parker ZB09

2-way Electro Valve for Nuova Simonelli part 04100029 with Parker ZB09 coil

People who viewed this item also vieved

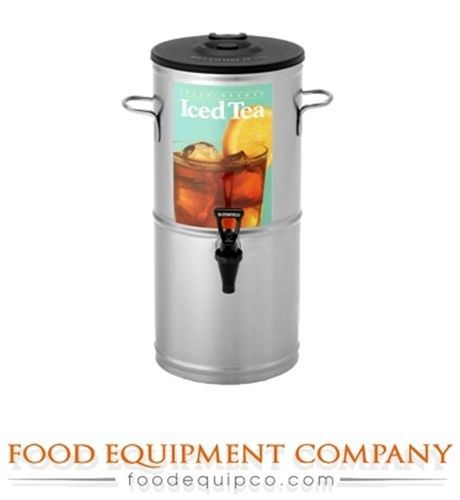

Bloomfield 8799-3G 3 Gallon Iced Tea Dispenser

Bloomfield 8602-5G-SG iced tea dispenser 86025gsg

Rattleware 6 by 5-1/2 by 6 Inch Knock Box

ORIGINAL NEW EXCLUSIVE BARISTA TAMPING CORNER MAT SILICONE BLACK WITH INSERT

Espresso Supply 02332 8" x 6" Packing Mat New

Bunn TF Urn Server 1.5 Gal ThermoServer Brown 39550.0223

120/208V Grindmaster PB-330 1.5 Gallon Single Shuttle Coffee Brewer

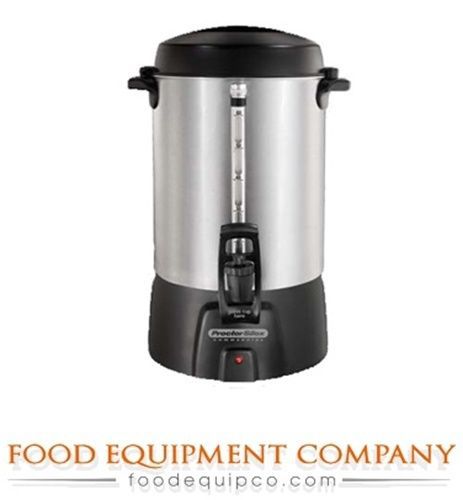

Hamilton Beach 45060 Proctor-Silex® Coffee Urn 60 cup/2.34 gallon capacity

Bloomfield 7878-THS Thermal Server Stainless Steel 1.9 L

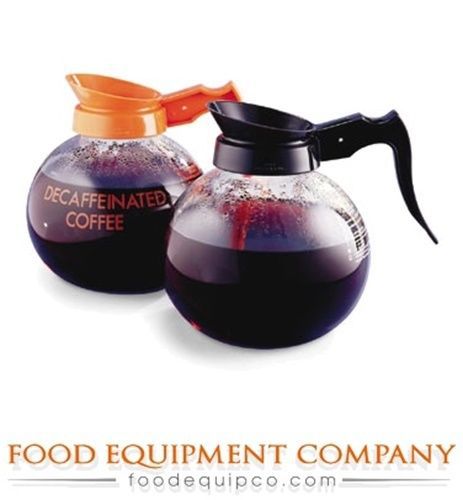

Hamilton Beach 89212 Decanters set of 2 - Case of 2

BUNN G9 Series G92 HD Coffee Espresso Bean Dual 2 Hopper Grinder commercial

Galleany Manual Ceramic Coffee Grinder - Best Adjustable Conical Ceramic Burr

Ceramic Burr Manual Coffee Grinder Portable Hand Crank Stainless Coffee Mill New

newco bistro 10-t liquid coffeee maker

Bunn 44000.0005 TF 1G Server Gen3 Stainless Steel with Base

Commercial Bunn Td4t 4 Gl Iced Tea Dispenser

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies