US $190

Directions

Similar products from Welding Protective Jackets

Welding Jacket-made in the USA

Revco Industries BX-KK-18T BSX Double Layer Cut Resistant Kevlar Sleeves 18-I...

GUARD LINE (2) WELDING JACKETS 2XL FLAME RESISTANT NEW 100% COTTON

WESTEX PROBAN FR-7A (2) WELDING JACKETS 2XL FLAME RESISTANT NEW 100% COTTON

Cinch White Label Worx FR Jeans Flame Resistant 38x34

Weldding Sleeves Flames resistant Hot Heat Safety Security Protective Gear Power

Steiner 12122 Cape Sleeve With 14-Inch Bib, Domestic Brown Split Cowhide, Large

Hobart Welders Leather Welding Jacket XLarge 770488 Dark Brown Fast Ship!

Lincoln Electric Traditional Welding Gear Ready-pak (Size Large)

Lapco 7oz Western Plaid FR Shirt ILU7WS XL

Leather Welding Half Jacket with bib- Small

Hobart 770486 Leather Welding Jacket - XL

MILLER ELECTRIC Black Pigskin Leather Welding Jacket, Size: 3XL, 30" Length

TYNDALE FIRE RESISTANT JACKET SHIRT COAT ARC RATING ATPV 17.1 M L DARK BLUE USA

NWT RADNOR Welding Jacket Leather Sleeves Snap Front Flame Retardant 2XLARGE

850-LARGE-REG Mid-Weight Welders Shirts 100% Cotton 8.5 oz Large Reg

Revco Industries BX-KK-18T BSX Double Layer Cut Resistant Kevlar Sleeves

People who viewed this item also vieved

Lincoln Electric 4-1/2 x 5-1/4 Welding Helmet with No.10 Lens Excellent

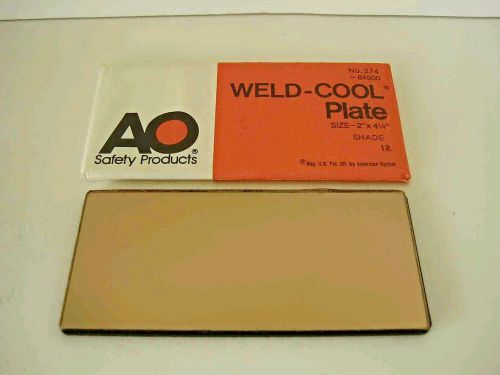

AO Cool Blue American Optics Weld Cool Shade #12 Welding Lens 2" X 4.25" #274

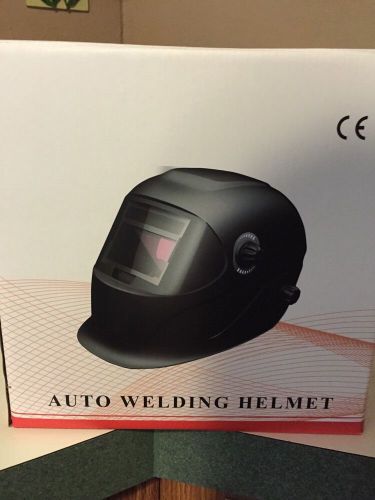

Pro Solar Welder Mask Auto-Darkening Welding Helmet Arc Tig mig grinding

Hobart 770274 Magnifying Helmet Lens, 150X

Radnor Leather Shoe Protector - Radnor Leather Shoe Protector -

GENTLY USED PAULSON IM23-ARC-PC-10 ARC FLASH FACESHIELD NFPA 70E HRC2

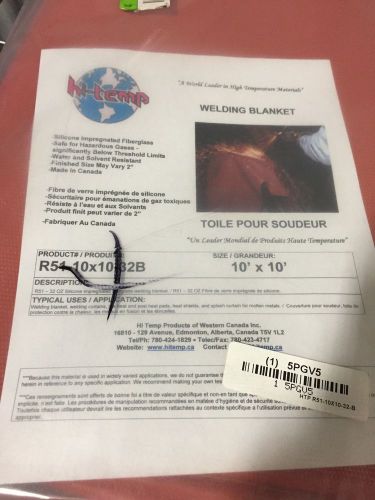

HI TEMP R51-10X10-32-B Welding Blanket, 10 ft. W, 10 ft., Red

202911119 Classic Black Frame with Indoor/Outdoor Mirror Lenses Safety Eyewear

Radnor Lift Front Welding Goggles #64005088

Hot Max Welding Goggles Fixed Front 2"x4 1/4" #5 Shade Model 25030 New

Steampunk Vintage 1970's Welding Googles

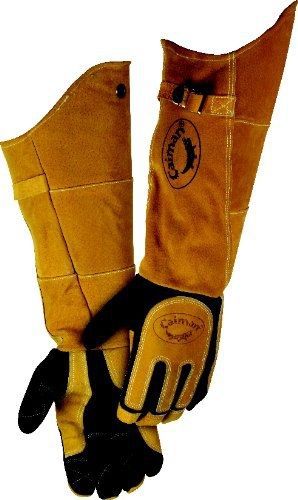

Caiman 1878-0 Left Hand Only 21-Inch One Size Fits All Genuine American Deerskin

TILLMAN 1414S DRIVERS GLOVES SMALL Split Cowhide (Lot Of 12 Pairs) FREE SHIPPING

Steiner 0223L TIG Gloves, Grain Sheepskin Unlined 4-Inch Cuff, Large

Steiner 02109F Welding Gloves, Brown Shoulder Split Cowhide Foam Back Palm

Steiner Industries 4" X 11" Cowhide Rod Holder ~ 12190

TILLMAN BIB LEATHER APRON T4242

Universal Joyutoy Yellow Welding Bib Apron Cowhide Split Leather Safety Apparel

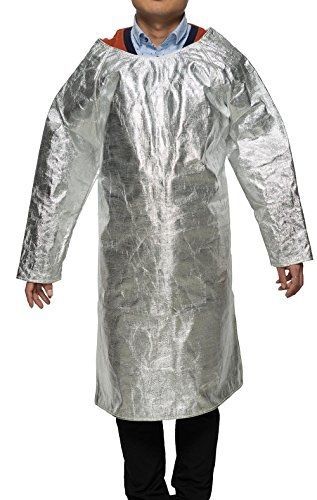

Unknown Welding Apron Aluminized Heat Resistant Apron Protective Coat Safety

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies