US $32,500.00

| Condition: |

Used: An item that has been used previously. The item may have some signs of cosmetic wear, but is fully

operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

...

|

Brand | Thermwood |

| Model Year | 2003 | ||

| Control | CNC |

Directions

Similar products from Professional Router Machines

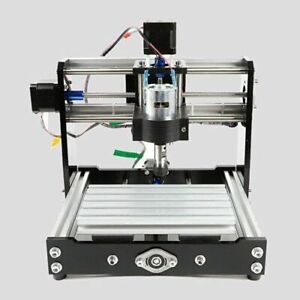

2-in-1 7000 m W 3018 Pro CNC Router Kit, Mcwdoit GRBL Control 3 Axis Wood Plasti

2-in-1 2500 m W 3018 Pro-M CNC Router Kit, GRBL Control 3 Axis Wood Plastic Acry

MYSWEETY CNC 3018Pro-M Engraver Machine Kit, GRBL Control 3 Axis Mini DIY CNC Ro

TBVECHI 3 Axis CNC 3018 PRO Router Engraver 5500mw Engraving Machine Upgrade Ver

3018 Pro Y-axis Extension Kit, Upgrade 3018 to 3040, Compatible with 3018 Pro

USB 4Axis 1500W 6040 CNC Router Engraver Metal Drill Mill Cutter+Controller 220V

2 in 1 5500mW Engraver CNC 3018 Pro-M Engraving Machine, GRBLControl PCB PVC CNC

Series2 Vision Engraver Controller

Shapeoko 3 XXL CNC router, PC, cutters, spare parts, steel belt kit installed

JoinTech IPM VERTICAL PUSH FIXTURE Patent Number 5018562 for use with IPM Fence

from US CNC 3018 Woodworking Carving Engraving Machine Laser Machine Mill PCB

USUSB Port 110V 4 Axis 6040 2.2KW Water Spindle Motor USB Mach3 CNC Machine

US 3018 pro cnc router mini diy engraving machine milling pcb pvc wood cutter

USB 4 Axis CNC 6040 2.2KW Spindle Engraving Woodworking Cutting Milling Machine

Enco Wood Shaper Model 150-6000

3 Axis CNC 1018 PRO DIY Router Mini Engraving Machine Engraver GRBL Control

NEW CARBIDE 3D SHAPEOKO 4 CNC ROUTER CONTROLLER KIT

US2200W CNC Router 6040 4Axis Mach3 USB Engraver Drilling Milling Machine 110V

4 Axis Router CNC 6040 Engraver Machine USB Engraving Drilling Carving 1500W

Cincel para tallado en madera 7L / 22 Herramientas para tallado en madera Cuenco

People who viewed this item also vieved

Rockwell delta drill press column ring

Rockwell delta drill press front belt guard

Rockwell delta drill press column to table piece

FIVE SHOPMATE MADE FOR SHOPSMITH WOOD WORKING CHISEL LATHE TOOLS

Powermatic model 90 wood lathe vintage Made in U.S.A single phase Complete

POWERMATIC Model 45 wood turning lathe

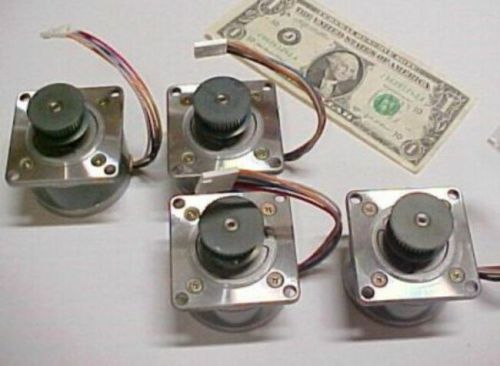

Lot 4 Stepper Motors Lathe, 1.1 Amp DIY CNC Router 103-775-7241 Sanyo Denki NEW

Delta Rockwell Unisaw Pointer Bracket & Angle Gauge

Dynabrade 52515 BRAND NEW Right Angle Pneumatic Air Disc Sander

Delta Rockwell 10" Unisaw Table Saw. Perfect Working Order. Best Offer!

DeWalt AMF Radial Arm Saw Model 925 Power Shop (1959+\-)

Industrial sawmill deck saw insert teeth with rivets

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies