US $120

Directions

Similar products from Welding Rods & Wires Sets

Blue Demon ER70S6 X .035 X 11# Spool Carbon Steel Welding Wire

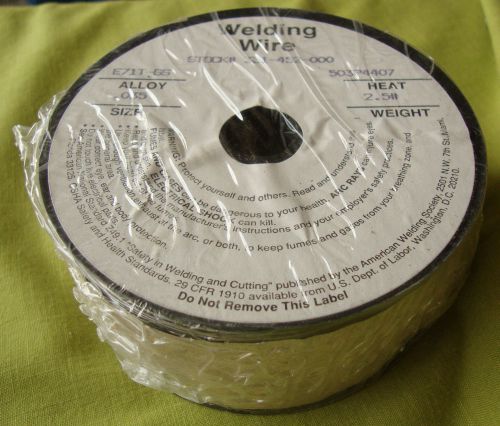

Welding Wire E71T-GS .035Dia, 2.5lbs, Heat 503P4407 Stock # 331-452-000

Blue Demon E308L-16 X 1/8" X 14" X 1# Tube Stainless Steel Arc Welding

Chicago Welding FLUX CORE WELDING WIRE E71T-GS 0.035" 2LB 44877 NEW

BLUE DEMON WELDING PRODUCTS E7018 9212 3/32" 2.4MM ALL POSITION ELECTRODE

Thermadyne 1440-0217 Firepower ER70S-6 Mild Steel Welding Wire 33-Pound Spool

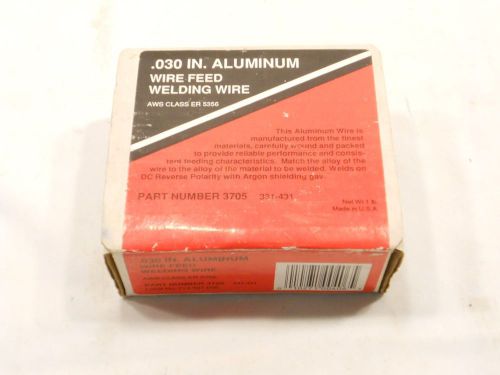

GULF WIRE CORP, .030 IN. ALUMINUM WIRE FEED WELDING WIRE, LOT 3987, TYPE 5356

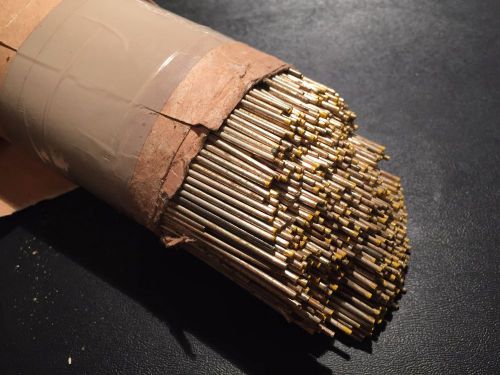

Harris 04043605 4043 Aluminum TIG Welding Rod 1/8" x 36" x 5 lb. Box Harris 5103

40% Silver EutecRod 1601 1lb Low Temp Brazing Soldering Rod, 1/16", PRO QUALITY!

Stay Silv 15 HARRIS COPPER BRAZING ALLOY p/n 15620F15P

Maxel Mig 1Lb 1.2mm,Aluminum welding wire,Alloy ER5183,0.47"-3/64",P#518304704

Weld-aid 6 Red Kleener Pads & Wire Kleener and Lubricant

Forney 42330 Copper Coated Brazing Rod, 1/16-Inch-by-36-Inch, 5-Pounds

MIG WELDING STEEL WIRE 2 ROLLS 2# EACH, 0.035" NEW

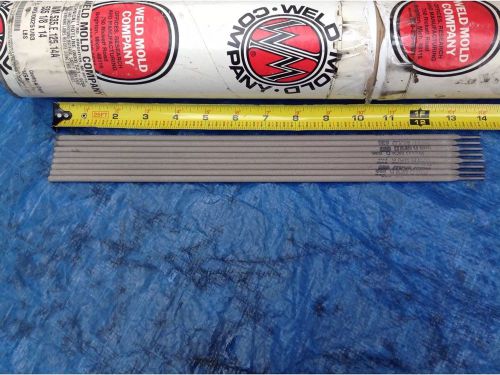

Weld Mold Weld Welding Electrodes Rods 3/16" x14" 535 10lbs WM 535 E 187 14A

Weld Mold Weld Welding Electrodes Rods 3/16" x14" 927 10lbs WM 927 E 182 14A

Weld Mold Weld Welding Electrodes Rods 1/8" x14" 535 10lbs WM 535 E 125 14A

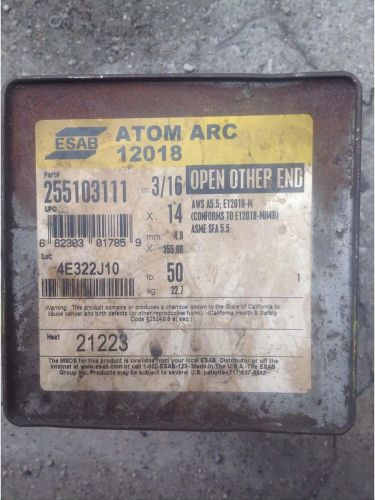

ESAB Atom Arc Welding Weld Rods 12018 3/16" 50 lb 21223 255103111

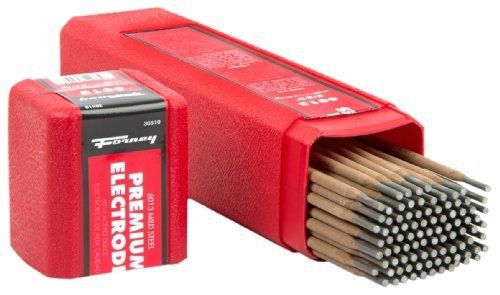

Forney 30510 E6013 Welding Rod, 5/32-Inch, 10-Pound

People who viewed this item also vieved

Tregaskiss Checking Fixture 45 Dgr RW1-3200-45

D/F MACHINE SPECIALTIES WELDING GUN MTW-MINI WATER COOLED ROBOTIC TORCH NEW A21

MK Products gas cup Cobra Prince guns 001-0137,001-0138,001-0139 (10 pc lot)

Magnum M16291-2 Mig Gun Liner Fits 100L, 025-.030 15 ft TWECO 23-40-15

Miller MIGmatic 248282 M-100, 100A MIG Gun 10 FT .030-.035 Wire

Bernard Q3015AE8HM Q300 300-Amp Q-Gun MIG Gun and 15' Hose Assembly

(4) Miller 189823 Insulators, Front Bearing, New In Bag!

SUZUKIT Welding Extention Cable 10m

SUZUKIT Oxygen Connector Plug (3/8in 9.5mm)

SUZUKIT Filter Plate #10 50pcs

SUZUKIT Compact Welding Machine 0.7 Burner

Welding Chipping Hammer & Interchangeable Steel Brush

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies