US $10,000.00

| Condition: |

Used: An item that has been used previously. The item may have some signs of cosmetic wear, but is fully

operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

...

|

Brand | Data IO |

| MPN | 2500 | ||

| Model | ProMaster | ||

| Country/Region of Manufacture | United States |

Directions

Similar products from Testing & Assembly Equipment

CYMER, INC CAGE CODE: OSMX8 123760 SUNTRON CORPORATION CY123760

Digital Dynamics 27-10157-00 I/O Controller Novellus (Untested)

Keithley S425 Parametric Tester

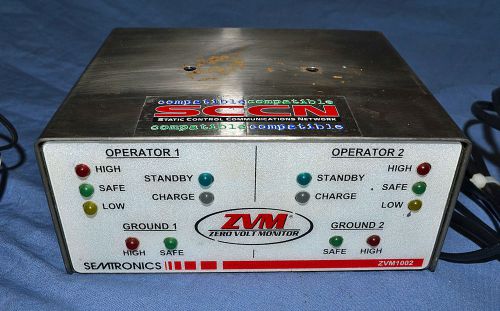

Semtronics SCCN ZVM1002, 2 Operator Static control Communication network

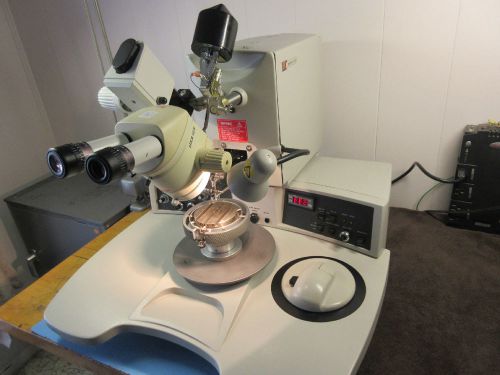

K&S 4522 Semiconductor Wire Bonder & Leica MZ6 scope & RH Mouse Kulicke & Soffa

UNITEK MICROPULL I 6-092 03 bond pull strength testing Tool Machine

4 Swagelok SS-PB4-PM4 Push on hose barb 1/4 inch, new in sealed bag

Guzik S-1701A, ANA 971++, RWA 2550++, & Much More !

Agilent/HP 4145B Semiconductor Parameter Analyzer

KULICKE & SOFFA MODEL #4129 Vertical Feed Ultrasonic Wedge Bonder (#902)

Temptronic TP0315A-TS-1 Thermal Vacuum Chuck Controller for Wafer Test

FORCE COMPUTERS PME 030416-02 PPC POWER CORE CPCI CYMER INC.

![[6UNITS] SWAGELOK QC6 QUICK CONNECT FITTING 3/8 SIZE (#1)](/_content/items/images/54/3707554/001.jpg)

[6UNITS] SWAGELOK QC6 QUICK CONNECT FITTING 3/8 SIZE (#1)

![[3UNITS] SWAGELOK QC6 QUICK CONNECT FITTING 3/8 SIZE (#2)](/_content/items/images/52/3707552/001.jpg)

[3UNITS] SWAGELOK QC6 QUICK CONNECT FITTING 3/8 SIZE (#2)

MICROHANDLING Manipulator MP 921M Semi Electronics Mfg-From Working Environment

MICROHANDLING Manipulator MP 921 Semi Electronics Mfg- From Working Environ.

Chatillon DPP-5 Force Gage stand pull strength spring tester

Micromanipulator 7000 with Enclosure and Table

Guzik S1701MP Hard Drive Spinstand with RWA-1632 PRML, ANA-961 PRML & Computer

Rohde&Schwarz SMIQ06ATE Signal Generator 300KHz~6.4GHz

People who viewed this item also vieved

Fujikin Stainless Steel C-Seal/Tube Fitting CWL-4X4BW

Simco Aerostat XC Ionizing Air Blower 4002612 Static Neutralizing 115 V ac

Honda Electronics Pulse Jet Ultrasonic Cleaner Controller W-357-1M w/ Blemishes

2008 WPS 6 FOOT STAINLESS WET BENCH / PROCESS STATION W/ FLAME SUPPRESSION

Praxair X305-80-120-H-212 CMP Polishing Pad 30.5" Window Pad Lot of 6 New

Brooks Automation Circuit Board PCA 11720/C PCB 11719 Rev. C, Free Shipping

KLA Tencor Prometrix Servo Fuse Adapter PCB 36-0297 Rev. A, Free Shipping

AMAT 1200-01067 RELAY CNTACTOR ABB 300 Amp 24VAC Coil EH160 NEW EH-160

TEL TOKYO ELECTRON Chemical Vapor Deposition Pipe

TEL TOKYO ELECTRON Alpha 8 Vertical Furnace Industrial Part

TEL TOKYO ELECTRON Alpha 8 Vertical Furnace Corrugated Clamp Bellow

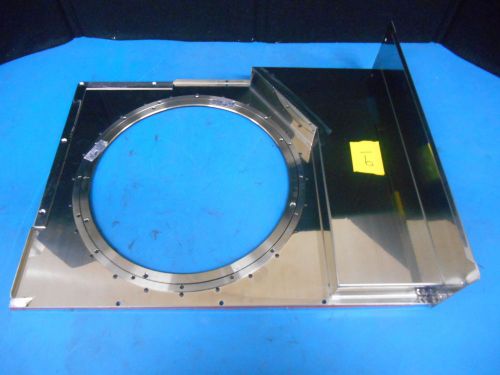

TEL TOKYO ELECTRON Alpha 8 Vertical Furnace Chamber Shroud

D101565004 VARIAN IMPLANTER COMMUNICATIONS PCB

Entegris 200 mm Ultrapak wafer shipping boxes

Asyst 3200-1251-03 Spartan Door Controller PCB & 4002-5466-01 4002-6712-01A Assy

Asyst 9701-1058-05A Hold Down Node PCB w/ 4002-5679-01 9701-0135-01 Assembly

ADAPTEC ASSY BIO-RAD QUESTAR 585201-00 BIOS 4700 AHA-1520A 100-Day Warranty!

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies