US $3,499.99

| Condition | Used

:

An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “This unit is being sold as-is, untested. The computer is not included but is needed to run it in its current configuration.” |

Directions

Similar products from Printed Circuit Boards Assembly Tools

Zephyrtronics ZT-1 Preheating Hot/Cold Analog Airbath

Universal Instruments Feeder Bank with Feeder Carts SMT PCB Pick and Place UIC

Universal Instruments 32mm Feeders with Feeder Cart SMT PCB Pick and Place UIC

Universal Instruments Sanyo HSP Feeders with Feeder Cart PCB Pick and Place UIC

Universal Instruments 44mm Feeders with Feeder Cart SMT PCB Pick and Place UIC

Universal Instruments 24mm Feeders with Feeder Cart SMT PCB Pick and Place UIC

Universal Instruments 16mm 56mm Feeders with Feeder Cart PCB Pick and Place UIC

Speedline/MPM PC-257/E Motion Cards (Lot of 4)

LARGE LOT OF AIR-VAC NOZZLES BGA AND OTHERS

Siemens Siplace ML 05 Magazine loader

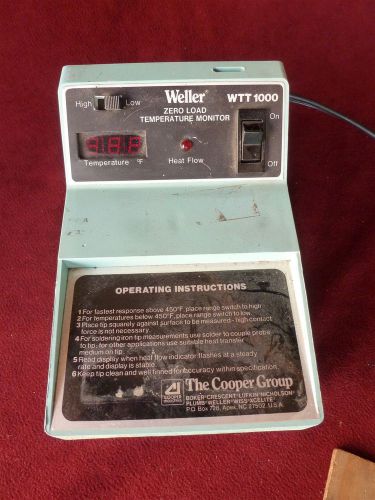

Weller WTT1000 Soldering Station base iron Variable WTT 1000 Working

14pcs of PANASONIC Tape Cutter X050-926T

4pcs of Lead Cutter X036-116 X036-117 and 1pc of Lead Line Guide X036-031

10pcs of PANASONIC Tape Cutter X036-037

Tegal March PLASMOD Tabletop Plasma Reactor Asher PCB Etching Etcher System

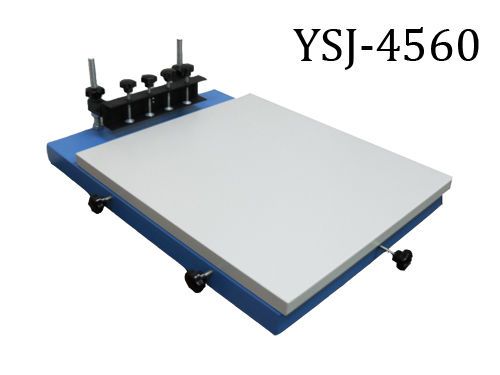

YSJ-4560 Large Manual Stencil Printer

AIR-VAC FWL 12 - 44 PCBRM Flow Well Solder Fountain Nozzle

Universal 6360A Rad 3 Radial Inserter 2.5/5.0 mm lead span 20 Station W/ BEC

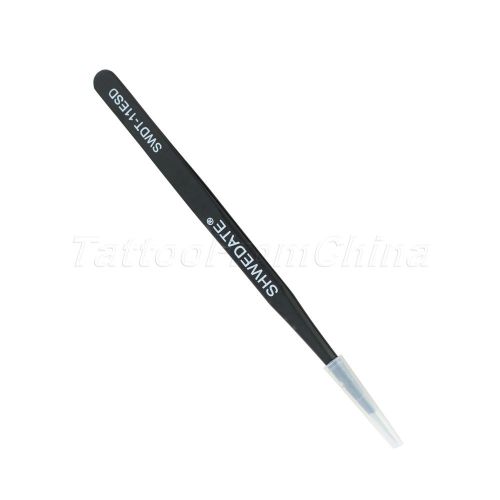

New 14cm Steel Anti-static Non-magnetic Fine Tip Straight Tweezers Forceps Tool

1 pc of Universal Instrument GSM part Nozzle Adaptor Fixture 45243603

People who viewed this item also vieved

Cognex In Sight 1700 wafer reader, Fully Tested!

10X-20X-30X-60X Binocular Stereo Microscope+80 LED Ring Light

2-270X Stereo Microscope+Cold Light+0.3X0.5X Barlow+10X30X Eyepieces+10MP Camera

AAF Astrocel II Cleanroom HEPA filter

AMAT 0010-11806 ASSY, Double Ended Transfer Chamber

NEW Turck RSC-3VBRK-RKC-5724-2M-0.2M-0.2M-0.15M Cable/Cord U-48499

Teradyne EBM Papst 873-103-04/FI-800-950-001 w/R1G220-AB07-09 24V Double Fans

NEW Turck RSM-RKM-5711-30M/C1126 Male/Female Straight 5-Pole MiniFast Cord/Cable

Euclid Vidaro Microdenier Polyester Modesty Scrubs, Cleanroom, Lab Wear sz lg

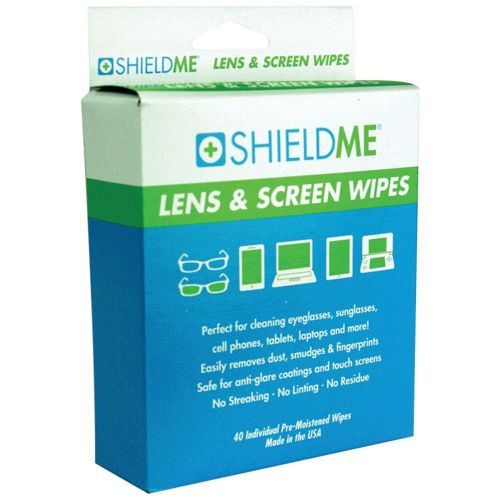

BRAND NEW - Shieldme 2435 Lens & Screen Cleaning Wipes, 40 Ct

BRAND NEW - Shieldme 2202 Lens Cleaner With Cloth In Cap, 2.2oz

PCB Printed Circuit Assembly Design pro engineering complete info

Leica Leitz Adjustable Arm 020-603.019-000 & Brightlight 307-148.004

EQUIPE TECHNOLOGIES FPD-3101 WAFER TRANSFER ROBOT - MISSING COVER

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies