US $2400

Directions

Similar products from Heat Pressure Equipment

Heat Press Sublimation Pillow 4 pack (W= 0.50" 6"x8", 5"x14", 12"x12", 16"x20")

New Silicon Rubber Mat Pad 16x24", for Flat T-shirt Heat Transfer Press Machine

110V 16" x 24" New Swing Away Manual T-shirt Sublimation Heat Press Machine

110V 16" x 20" New Swing Away Manual T-shirt Sublimation Heat Press Machine

Seal Compress 110S Laminating Press

3D Phone Case Sublimation Vacuum Heat Press Machine Professional good new

3D Phone Case Sublimation Vacuum Heat Press Machine Professional new machines

3D Phone Case Sublimation Vacuum Heat Press Machine Professional hot quality

DIGITAL HEAT PRESS MACHINE T-SHIRT SUBLIMATION PRINTER TRANSFER 16"X20" PRESSING

5 in1 Heat Press Machine Heat Transfer Machine T-shirts/Caps/Hats/Plates/Mugs

8 in 1 COMBO HEAT PRESS TRANSFER SUBLIMATION Plus PRINTER EPSON START UP PACK

2pcs/lot-3D Sublimation SAMSUNG S5 Phone Case Cover Heating Tool Mold

3D Smart Vacuum Phone Cases Heat Transfer Press Machine Sublimation

Geo Knight 394-TS Jumbo 20"x25" Shuttle Press With Air Assist Upgrades

15x15 Heat Press,13" Metal Vinyl Cutter Plotter,Transfer Paper,PU Vinyl Bundle

Dablo Presscobar: 12,000lb Hydraulic Dual 5x5 Heated Plate Rosin Press

Geo Knight | DK8T Model | Digital Twin Label Heat Press | Brand New

HIX HAT PRESS BASEBALL HAT HEAT TRANSFER PRESS VH-250

8 in1 Heat Press Machine Digital T-Shirt Mug Plate Cap Transfer Sublimation eqe

People who viewed this item also vieved

20sheets A4 Dark Inkjet Transfer Paper T-shirt Heat Press Transfer IRON ON

Neenah Photo Trans SC Laser Heat Transfer Paper 100 sheets 12x18 White 8.5x11

Transfermations DARK Design and Iron on Transfer Sheets 10 8.5 x 11 BRAND NEW

Inkjet heat transfer iron on paper for Dark color A4 SIZE-500 sheets

Red Grid Inkjet Light Colored T Shirt Heat Transfer Paper 8.5 x 11 (50 sheets)

NEENAH TRANSFER PAPER JET PRO SS LIGHT FABRICS 50 SHEETS

Inkjet Heat Transfer Sample Pack for Light & Dark Colors 8.5" x 11"

20”x3ft UltraFlex Heat Transfer PU Print Vinyl matte white+20"x3ft print mask

Camo Dip Kit Over 100 patterns Available From Camo4u

20”x15' Print Mask Premask Tape for Masking Prints/Cut-outs for Heat Transfer

APPLIED MATERIALS 5090-01013 402244R-X2 DGR HE-5 HEAT TRANSFER FLUID

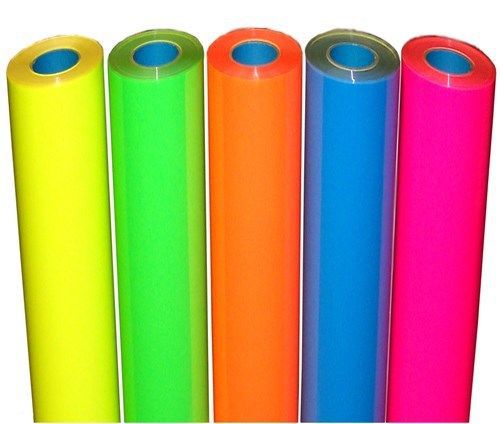

5rolls pack 20”x3ft Heat Transfer PU Vinyl, choice of 7 neon colors/gold/silver

5rolls pack 15”x3ft Heat Transfer PU Vinyl w/ sticky back,23colors;Cutter,Press

5rolls pack 20”x3ft Heat Transfer PU Vinyl, choice of 11colors for Cutter,Press

JCM® Iron On Applique Decal, Tribal Heart Neon Green

JCM® Iron On Applique Decal, Tribal Heart Sky Blue

JCM® Iron On Applique Decal, Flaming Skull Neon Orange

JCM® Iron On Applique Decal, Rabbit Silver

JCM® Iron On Applique Decal, Panda Silver

JCM® Iron On Applique Decal, Waving Panda Neon Green

JCM® Iron On Applique Decal, Tribal Star Neon Green

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies