US $1,250.00

| Condition: |

New other (see details): A new, unused item with absolutely no signs of wear. The item may be missing the original packaging,

or in the original packaging but not sealed. The item may be a factory second or a new, unused item with defects. See the seller’s listing for full details and description of any imperfections.

...

|

Model | IZO Sputtering Target bonded to Copper plate |

| Brand | Umicore Group |

Directions

Similar products from Cleanroom Gear & Expendables

SIMCO-ION 6422E-AC BENCHTOP IONIZER

NEW TECH WEAR 2XL BLACK V-NECK ESD / ANTI-STATIC JACKET

Materials Research Corporation UHV High Vacuum Semiconductor Pure Copper Toroid

Liberty 100FJ/T.B. Shoe Boot Brush Machine Cleaner House/Central Vacuum

CHARLESWATER CP912/120V ION PUMP BLOWER WITH HEAT

Blue M DCC-206C Clean Room Oven Cleanroom

SIMCO CENTURION 9E IONIZER/OZONATOR AIR BLOWER FREE SHIPPING

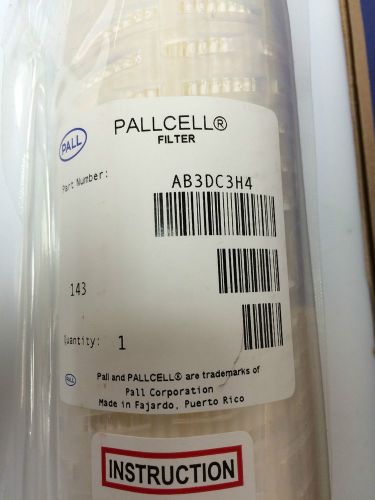

LOT OF 10 PALLCELL FILTERS AB3DC3H4

REAL Seal 8970-359 Silicone O-Ring Gasket Seal For High Temp Applications

REAL Seal 8970-200-340 Silicone O-Ring Gasket Seal For High Temp Applications

Simco CenturION9E Ionizing Air Blower

Flanders 0-009-4-19-04-SU-00-00-23G36Q6 Laminar Flow Grade VLSI Filter

TEQCOM TA-N2-2000 N2 PTFE Spray Gun Assembly - 5 pieces

TEK PRODUCTS 421-42-11 SPRAY GUN, NITROGEN, 1/4" NATL - 6 pieces

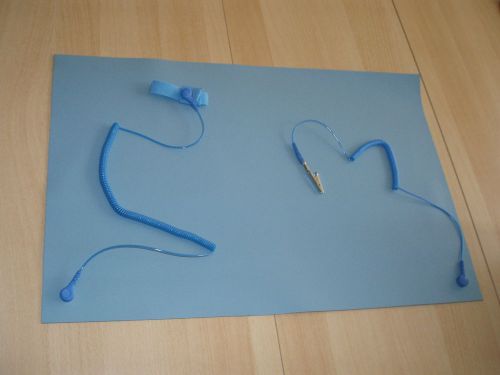

Industrial Grade ESD Mat 60x40cm cleaning room set

TWO 3M 724 Anti-Static ESD Wrist Strap Workstation Monitors

ENTEGRIS / NT INTERNATIONAL CM100 CONTROL MODULE CM100-FM2-A-A-B CM100FM2AAB

TIGER-VAC CLEANROOM VACUUM SYSTEM MODEL MV-1CR

MATING CONNECTOR FOR HIGH VOLTAGE BNC TYPE CONNECTOR AS IS BIN#28-91

People who viewed this item also vieved

Basler A311fc 1394a color camera, resolution: 659 X 492

NanoMetrics NanoSpec 8300 Automated Film Thickness Measurement System

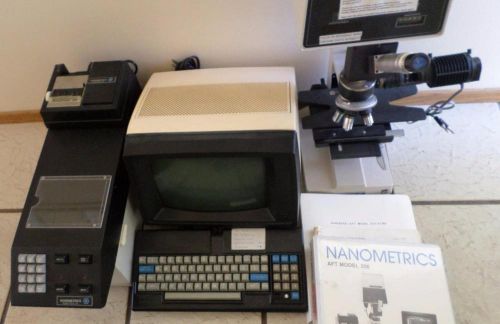

NANOMETRIC Automatic Film Thickness Measurement System AFT 200

Conveyor Technologies CC-.5-1-H-UL-HMI 1/2 Meter Conveyor

Conveyor Technologies XCC-.6M-1-SC-BR-AB 1/2 Meter Conveyor

Conveyor Technologies CC-.5-1-H-UL 1/2 Meter Conveyor

Pace TF-2700 BGA Rework Station SMD SMT Hot Air Soldering Alignment CSP QFN LCC

3 capacitor 0.1uF 250V with RADIA electronic new parts

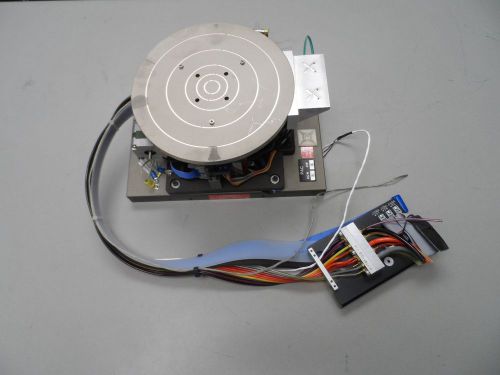

8" Silicon Wafer Chuck w/ assembly, pulled from an electroglas tool

TEL Unity II Sanritz Automation SVME/AT-BCN/A, SVA603A-1-S

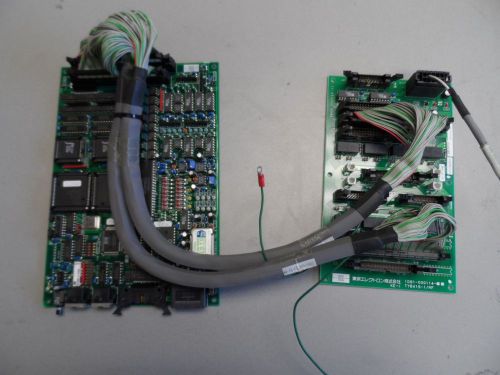

Tokyo Electron Ltd TEL Unity 1D81-000 & 1D81-000114 TYB415-1/RF PCB Assembly

Screen D-Spin 60A/80A Set of Manuals (See Photos and List Below)

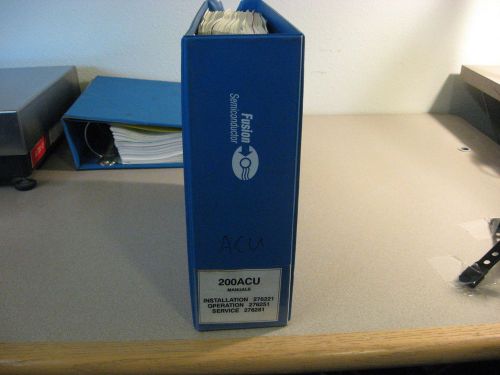

Fusion Semiconductor 200ACU Installation, Operation, Service & Schematics Manual

Leica Leitz Ergoplan Microscope System Manuals (See photos & list below)

Thomas Products 2706, 5GPM -- Model 2100 -- New

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies