US $7500

Directions

Similar products from Other Manufacturing Equipment & Tools

6 Inch WEST VIRGINIA WV State Shape Rusty Metal Vintage Stencil Ornament Craft

6 Inch CONNECTICUT CT State Shape Rusty Metal Vintage Stencil Ornament Craft

6 Inch NORTH CAROLINA NC State Shape Rusty Metal Vintage Stencil Ornament Craft

6 Inch ARKANSAS AR State Shape Rusty Metal Vintage Stencil Ornament Craft

6 Inch Virginia VA State Shape Rusty Metal Vintage Stencil Ornament Craft Sign

Lot of 5 Musical Intruments Shapes Guitar Piano 3"-6" Rusty Metal Vintage Crafts

3D Systems InVision LD 3-D Printer

6 Inch INDIANA IN State Shape Rusty Metal Vintage Stencil Ornament Craft Sign

1-1/2" OD Round Tube Die Set 5.5"CLR-90 JD2 Model 3 Bender USED

JET EDGE WATER JET FILTER # F-88-5

Serpentine Belt Tool OEMTools 27115

INDOCO 6' X 8' X 6' ELECTRIC INDUSTRIAL HEAVY DUTY WALK IN CONVECTION OVEN

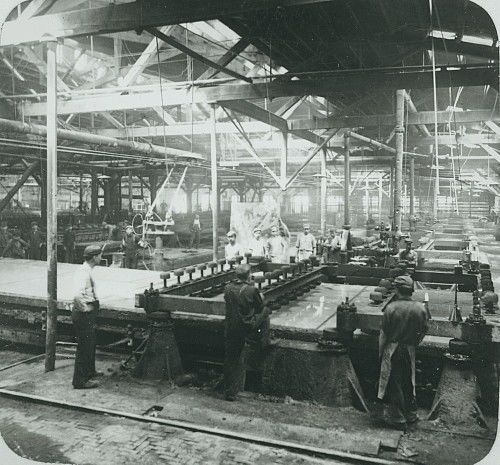

c1900 Tarentum PA Plate Glass Works Men Finishing Windows Lantern Slide

20,000# x 72" Dahlstrom Mandrel Type Coil Uncoiler

J-MAR PRECISION Measuring System / Model No. S2610-01

Mori Seiki MV-55 50 Taper CNC Vertical Machining Center Mill, Fanuc VMC cat chip

Niigata SPN 50 CNC Horizontal Machining Center Mill Fanuc 12000 RPM cat 50 40 HP

KINE-SPIN 402-E Fluid Extractor

People who viewed this item also vieved

12 Brass 27 MM Brass Round Blank, , Brass Disc. Jewelry Material

12 Brass 22MM Brass Round Blank, , Brass Disc. Jewelry Material

C360/360 BRASS HEXAGONAL BAR STOCK 1.010" X 12"

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies