US $269.00

Directions

Similar products from Stamping Machines & Embossers

New Xstamper Classix P14 Self-Inking Rubber Stamp 7 line text

New MaxStamp C-43 Custom Round OFFICE NOTARY Self-Inking Rubber Stamp

DIY 100 sheets Self Inking Flash Stamp maker Parchment Paper Isolating Film

Xstamper Classix P12 ECO GREEN Self-Inking Plastic 3 line Business address Stamp

Xstamper Classix P13 ECO GREEN Self-Inking Plastic 4 line For Deposit Only Stamp

NEW ECO GREEN Xstamper Classix P14 Self-Inking Plastic 7 line custom text Stamp

NEW BLACK 2 oz. Trodat / Ideal Re-Fill Ink for self-inking stamps

NEW Trodat Printy 4810 Self Inking Printy Dater Stamp

NEW Trodat Multi-Color Professional 5203 Custom Return Address Stamp with logo

Kensol / Franklin 115AS Hot Stamp Machine 2" x 6"

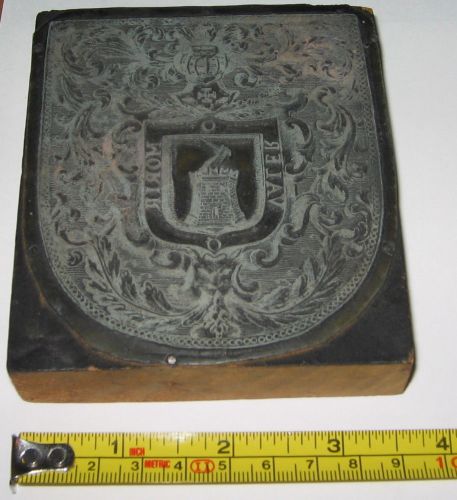

Old Printer Block Motto Stamp Family Crest O Valer O Morir Valera/Valero/Bolero

Commercial ID Badge Credit PVC Paper Business Card Die Round Corner Cutter Punch

60 pcs Stamp Various Shape Pre-inked Flash Stamp with Crystal Handle

260mm x 210mm UV Stencils Timer Exposure Unit Machine W/6 X 8W UV Lamp CE

New UV Exposure Unit for Hot Foil & Pad Printing W/ Stencils Timer

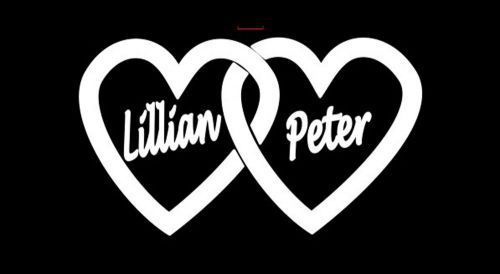

NEW Custom Names wth Love sign Wedding Personalized Shiny EZ-Seal Embosser

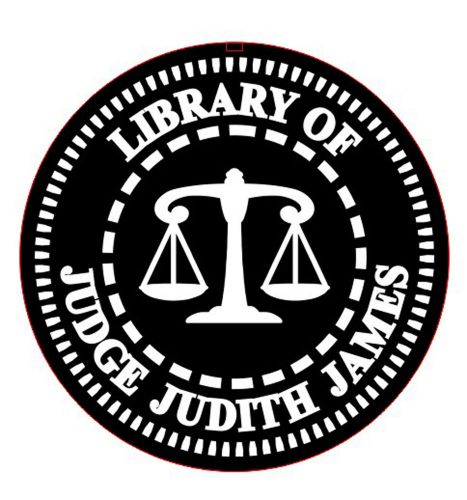

Personalized LIBRARY OF JUDGE Embosser Circular Layout Shiny EZ-Seal HandHeld

FROM THE DESK OF Caduceus or Medical Sign Embosser Circular Layout Shiny EZ-Seal

NEW pre-assembled Round Embossers Set of Die plate & Metal insert (no handle)

NEW CUSTOM Set of Interchangeable Embosser Plate / Die for handheld Embossers

People who viewed this item also vieved

VASTEX SCREEN PRINTING DIGIT NUMBERING SYSTEM USED ONCE!

5 - Newman roller screen printing frames 28x20id

4 Color 4 Station Screen Printing Press Machine Kit Exposure Unit Flash Dryer

Desk Plate Holders (Double Sided) Over 40% Below Wholesale

AWC708C LITE Laser Controller System CO2 Laser Cutter Engraver SHIP FROM USA

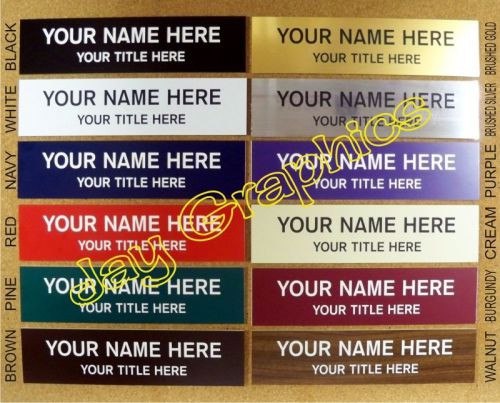

Custom Engraved 2x6 Name Plate | Personalized Customized Wall Door Desk Tag Sign

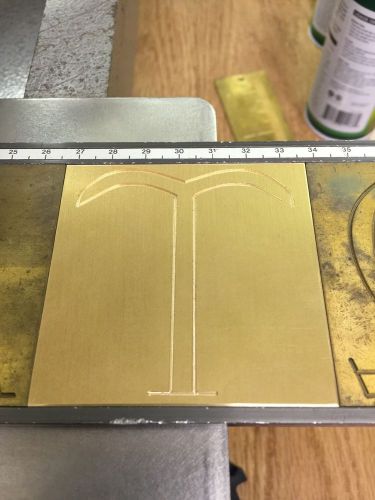

GREEK CUSTOM LETTER BRASS ENGRAVING PLATE FOR NEW HERMES GRAVOGRAPH FONT TRAY

BROTHER GT-361 GT361 DTG DIRECT TO GARMENT PRINTER WITH MANY EXTRAS

GRAUEL PRINTING MARKING HANDLING MACHINE NR B3200808

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies