US $140.00

| Condition: |

New other (see details): A new, unused item with absolutely no signs of wear. The item may be missing the original packaging,

or in the original packaging but not sealed. The item may be a factory second or a new, unused item with defects. See the seller’s listing for full details and description of any imperfections.

...

|

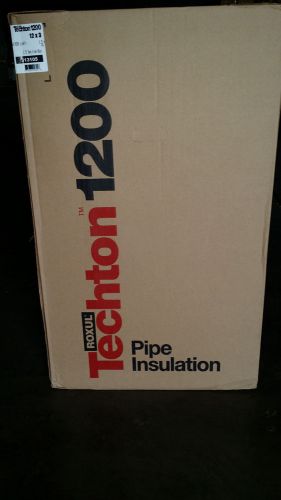

Brand | Roxul |

| MPN | 312351 | ||

| Model | Techton 1200 | ||

| Units Per Box | 6 |

Directions

Similar products from Weather & Acoustic Insulation

1000 sqft Radiant heat barrier Attic foil made in the USA 250' on a roll

Radiant Barrier Solid Silver 500 sq./ft.(48"x125') Meets newest Fire Code

Fuzion 24oz Black Gun Spray Foam RV Waterfall Pond (Case of 12)

HILTI CF-DS 1 foam gun, foam, tools, crack filler, Foam dispenser CF DS1

Dow Great Stuff Gap Crack Foam Sealant 12 oz New

1000pcs M3 Insulating Tablets Insulation Bushing Insulation circle TO-220

Owens Corning R-30 Fiberglass Insulation Faced 16"x48" Local Pick Up

Roxul Techton 1200 Pipe Insulation 3.5" x 1.5" wall, 13.120 Linear Ft.

Roxul Techton 1200 Pipe Insulation 6" x2" wall, 9.840 Linear Ft. 312049

Roxul Techton 1200 Pipe Insulation 12 x 3 4.920 Linear Ft.

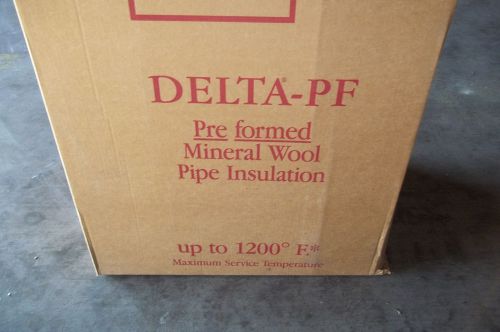

Delta-PF Pipe Insulation (Size-12) (Thickness-2.5) (FT-6) NEW

Roxul Techton 1200 Pipe Insulation 4" x 1.5" wall, 19.680 linear feet 312037

Glas Craft Graco Fiberglass Pressure Pot / Chamber 19" Tall - INDUSTRIAL ESTATE

BRAND NEW Roll VentureTape 3" x 50yd of ASJ Facing Tape 1540CW NT

Box of 10 Pemko Siliconseal Comercial Grade Door Insulation Seal - S88BL21-Black

DOW FrothPak 210 Spray Foam Kit

(120) HILTI CF AS CJP FIRE BLOCK INSULATING FOAM - HILTI SALE 10 cases

(72)Hilti CF 812 Window & Door Foam Pro Low pressure filler insulation

Great Stuff Big Gap Filler Spray Foam Insulation - 12 oz. Can

People who viewed this item also vieved

UniquExceptional UDC6 Outdoor Dome Fake Security Camera with BLINKING LIGHT (cho

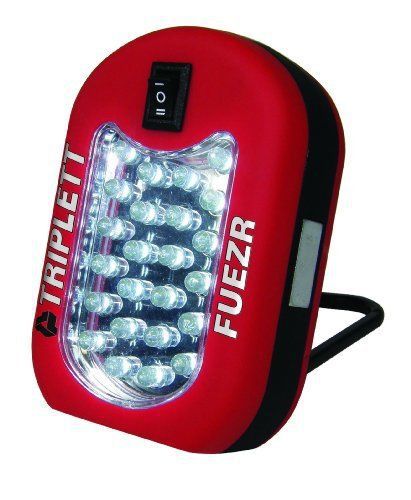

Triplett TT-101 FUEZR Multi-purpose LED Work Light with Case

Square D8903L01200 12 pole lighting contactor

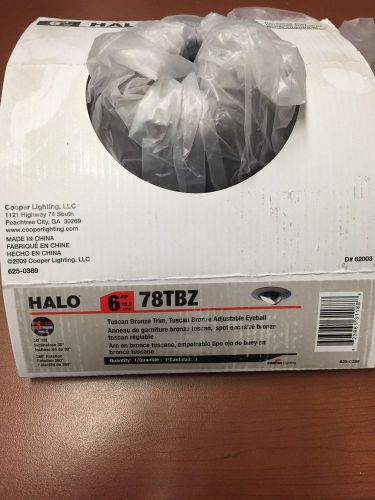

Halo 6" Trim Eyeball Tuscan Bronze Trim With Eyeball 30 Tilt 78tbz

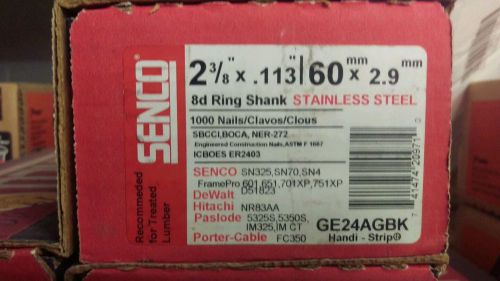

Senco Stainless Steel 2 3/8 Ring Shank Stick Nails 30-35 Degree GE24AGBK

Concrete Nails - 1/8" x 3/4" x 9 Gauge - 5 lb Bag

36" TAPER TOP PRIMED WHITE BALUSTER SPINDLES 28/BOX 5015 BALUSTERS

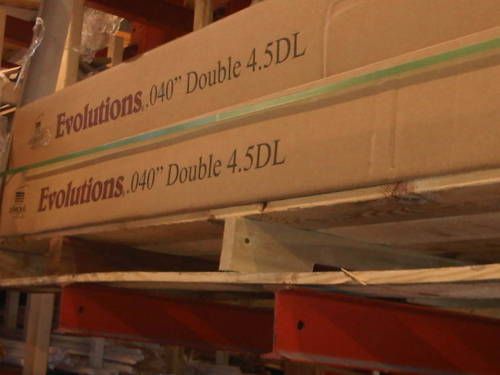

Cellwood Evolutions Vinyl Dutchlap Siding D4.5 - brand new in box

Prime Products 18-3320 5/8" ACE Camlock- Pack of 4

6 CARPENTER'S PENCILS RED & BLUE NEW STRONG

Red Devil 4044 Dual-Purpose Window Tool

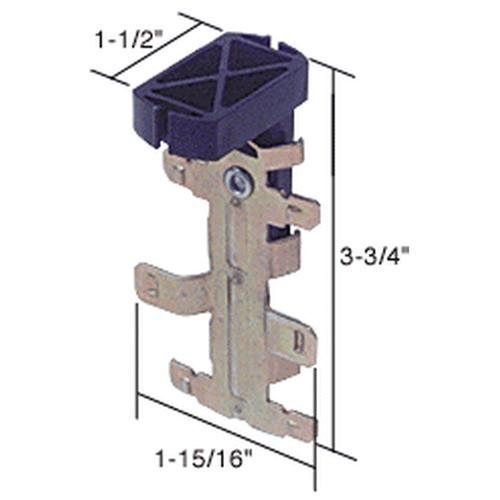

Wardrobe Door Top Plastic Guide for Cox Series 21 Steel Door Systems N6818

CRL Black 33S Silicone Sealant - 3 Pack of Cartridges

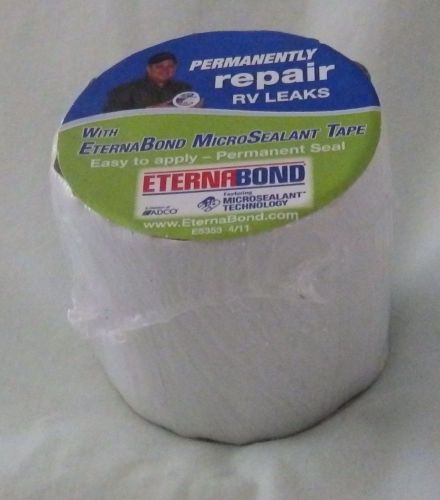

ETERNA BOND MICRO SEALANT TAPE permanently repair RV leaks

12"x4" 2-Way Wall Diffuser - White (set of 3)

Hart & Cooley 20" x 20" 043954 96AFBTI White Commercial Fixed Bar Filter Grill

6 Inch Diamond Blade Saw cutting Granite, Concrete, Tile, Stone, Marble, Slate

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies