US $1,106.00

Directions

Similar products from Fittings & Plates

1/4 Inch Precision Parallel Set (9 Pair)-NEW

FastBack Soft Jaws Set - Machined

MAG * MARO LOCATING PIN DET18 NIB * T.1014.1711-18

Haas auto Pallet Changer midaco

HEAVY DUTY TILTING BOX TABLE - RADIAL ARM DRILL PRESS - WORKHOLDING - T-SLOT

H/V 5C ANGLE COLLET FIXTURE (4-1/4 INCH H)

Aluminum Angle 1/2” x1/2” x 24 in,1/16 in thick, .5 IN, Angles, New, USA!

Aluminum Angle 1-1/2” x 1-1/2” x 24 in, 1/8 in thick, 1.5 IN x 1.5 IN, NEW!,USA!

Aluminum Angle 1 1/2” x 1 1/2” x 21.5 in,1/16 in thick, 1.5 x 1.5 in, NEW!, USA!

Rough Casting for 6" Chuck Back Plate

13" Diameter Face Plate for Lathe

7 1/2" Diameter Face Plate for Lathe

ERON ANGLE PLATE A TYPE NO 1 SIZE 3" x 2-1/2" x 2" JAPAN MACHINISTS TOOL

MACHINED ANGLE PLATE NO 22 SIZE 3" x 3" x 3" JAPAN MACHINISTS TOOL

OKUMA HOWA MACHINERY MILLAC 33T ACTUATOR ROTARY JOINT C1SB115X20 & DRAW BAR

Aluminum Angle 3/8 x 3/8 x 48 in, 1/16 in thick, NEW!, USA!

OKUMA HOWA MACHINERY MILLAC 33T 8' CHUCK & PLATE HO1MA8

OKUMA MILLAC 33T YAXIS BALLSCREW OH-2KK1-0002A H1014-0024-53 NSK W4006-1137PSSK1

Heinrich #1-AC Air Collet Fixture 150 lbs and foot peddel. parts list included

People who viewed this item also vieved

PARLEC NUMERTAP 7711 - #12 TAP COLLET CNC MILL BRIDGEPORT MACHINE SHOP

PARLEC NUMERTAP 7711 - #6 TAP COLLET CNC MILL BRIDGEPORT MACHINE SHOP

5/8 inch dia. MILL HOLD DOWNS TOE CLAMPS

Lot 6" D Clamp Duralast Adjustable Locking pliers CR-V

De Sta Co Model 830 Straight Line Air Cylinder

JACOBS DC4G61 Multi-Craft Chuck & Key 1/16 to 3/8" Capacity - Free Ship! (0191)

ATOPLEE Atoplee 1pc MT2 Live Center Morse Taper Triple Bearing 2 Mt .0002" for

PILE OF GRINDING LATHE DEAD CENTERS MACHINIST TOOLING LOT A

PILE OF GRINDING LATHE DEAD CENTERS MACHINIST TOOLING LOT B

Vintage Wilton 3.5" Jaw By 3" Opening Combination Pipe Bench Vise Anvil #121101

WILTON VISE USED 5" JAWS FOR OLDER 9500'S SCHILLER PK, C2'S

WILTON VISE USED JAWS FOR A 400S WITHOUT PINS 4 " WIDE, CLEAN!

LNS HYS 3.20-HS4.8 Super Hydrobar Bar Feed, New 1996

Fairlane CT-841-EF Carbide Tipped Gripper Round 3/8" Dia 10-32 Thread Lotof 2

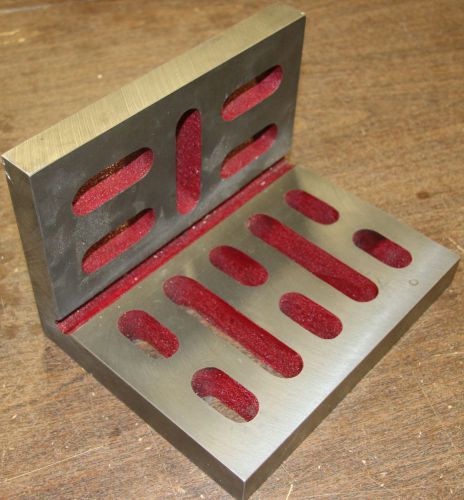

(1) Used 90 Degree Angle Plate Side one: 9" X 7" X 1 1/16" Side two: 9" X 6"X 1

TROYKE U-12 12" Vertical Horizontal Rotary Table - Great Condition!!!!

Haas Servo Control (for Repair/Parts only)

1,2,3 jobbing small blocks set double rows of holes

Starrett No. 568 Machinist V Blocks

"CandiBean Cling Stamp 4""X7""-Time For Tea"

3c DEAD TRUE Pneumatic collet closer, 3C,

"Penny Black Cling Stamp 4""X5""-Purr-fect Message"

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies