US $19.99

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

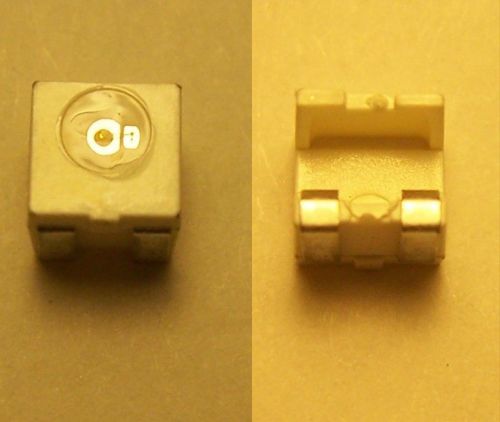

Brand | Everlight |

| MPN | 5MM-DIP | ||

| Model | WHITE | ||

| Country/Region of Manufacture | Taiwan | ||

| 5MM | HIGH BRIGHT | ||

| Color | White |

Directions

Similar products from Light Diods & Lamps

9w LED Indoor Outdoor Light Bulb 75w Instant On 4200 K USA American Seller 27e A

LED LIGHT TUBE - WHITE 12 VOLT - 18 INCH TUBE 12V SMD

H16 10W 900lm 6000~6500K 15-SMD 2323 LED White Car Foglight (10~30V) Z57

H4 10W 900lm 6000~6500K 8-2323 SMD LED White Light Car Lamp (10~30V) 4AQ

100pcs 2mm White Flat Top Water Clear 12000MCD LED Bright Leds Light + Resistors

1000pcs, 3mm Blue Candle Flicker Ultra Bright Flickering LED Leds Light Lamp New

100pcs, 3mm Blue Flicker 9V 12V Pre-Wired Water Clear LED Leds Candle Light 18CM

1pcs Warm White Mobile Power 5V Highlight USB Lamp 8 beads SMD LG 5152 LED new

50pcs Emitting Blue 0805 Super Bright DASH SMD SMT LED Light Lamp High Quality

20pcs White 15LM 5050 SMD 4-LED Waterproof Modules DC 12V Low Power Consumption

2PCS USB Touch Dimmer Lamp USB Touch LED Adjustable USB Touch Control Lamp 5 v

10'-3m 1.5mm optical fiber ESKA CK-60 fibre optic lighting light pipe Mitsubishi

Seoul Semiconductor Acrich2, SMJD-3V16W1P3, LED SMD 220V, 16 W, 5000 K,

Seoul Semiconductor Acriche, SMJD-3V16W1P3, Acrich2 AC 220 V, 16 W, 3000 K

OSRAM LGA679 GREEN LC SideLED SMD (30 PCS)

OSRAM LYT670 YELLOW LED SMD (30 PCS)

20pcs SMD White LED Module Perfect for Lilypad

100x 3mm LED Red Green Blue Yellow White Bright Light Emitting Diode Lamp 2pin

1000 Red 3mm LEDs Super Bright Clear

10PCS IR Infrared Emitter LED Lamp Diode 3mm 940nm new

People who viewed this item also vieved

20pcs. CL21 0.33UF 330NF400v P20 Metallized Poliester Film Capacitor Elecsound

20pcs. CL21 0.47UF 470NF400v P20 Metallized Poliester Film Capacitor,Elecsound

Lutron FDB-T426-120-1-S Flouresent Dimming Ballast

1000W 10ohm Aluminium Shell Braking Resistor Resistance dummy load for audio

1x UA309KC -( 5V 1.5A )- Voltage Regulator, Linear. Polarity:Positive = NTE309K

Sylvania Nf000Ud Sylvania Model 6626Lg Original Remote Control HDTV

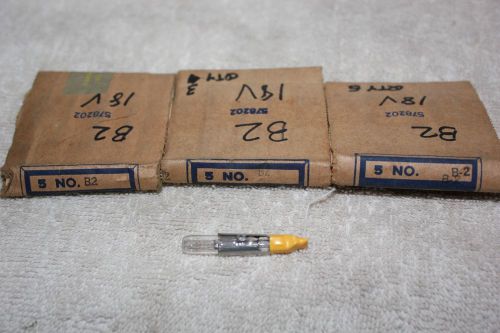

Western Electric B2 - 18V Switchboard Lamp (Qty 13) in original matchbook

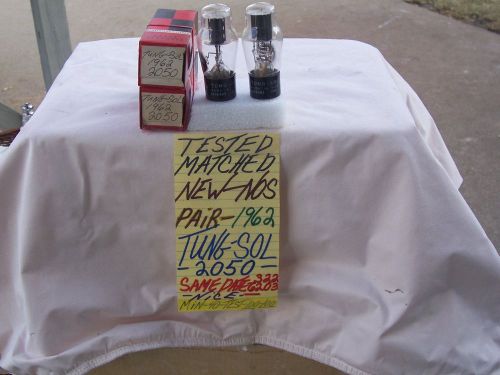

TESTED MATCHED NEW NOS PAIR TUNG-SOL 2050 SAME DATE 3226203 1962 TUBE 2050A

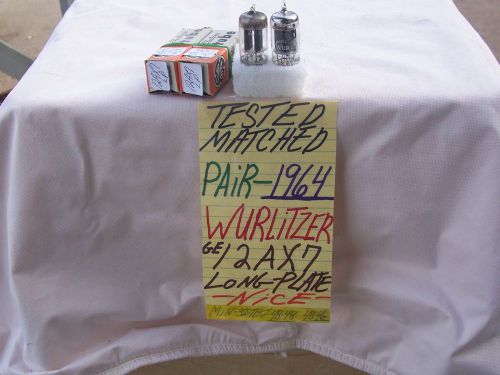

TESTED MATCHED PAIR GE WURLITZER 12AX7 LONG PLATE 1964 TUBE ECC83 12AX7A

10pcs Texas Instruments 555 NE555 IC Dip-8 USA Seller

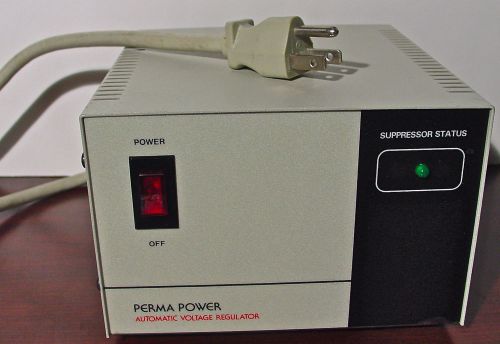

Perma Power AVR-600 Auto, Voltage Regulator /Transient Voltage Surge Suppressor

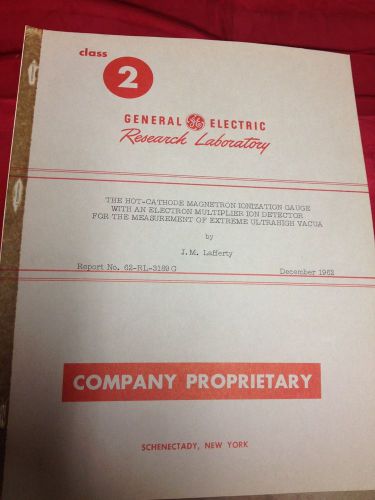

VINTAGE GENERAL ELECTRIC HOT CATHODE IONIZATION GAGES 1962 EXTREME ULTRAHIGH

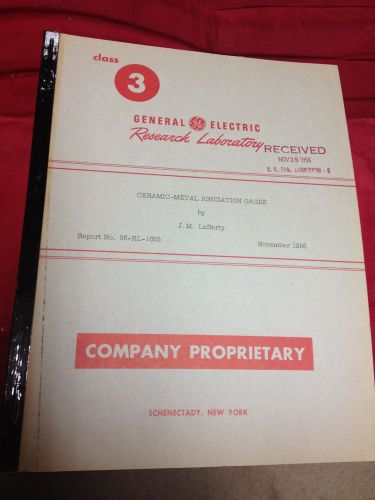

VINTAGE GENERAL ELECTRIC CERAMIC METAL IONIZATION GAGES 1956 PROPRIETARY OPENED

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies