US $1300

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Country/Region of Manufacture | China |

| product ID | 14469 |

Directions

Similar products from Other

QMI, Tensolite, Cable Assembly, SMA(M) 75Z - F(M) 75Z MFR 64023. 10pcs

Tensolite RF Cable Assembly: Workhorse: WHU18-1818-018, 18 inches N-type male

NUMATICS, Pneumatic Regulator Gauge 081RS100J

BIMBA, Air Cylinder 3/4 inch bore, P/N 046-DXP

Playstar Inc. PS 1100, Commercial Grade Dock Auger

Torq Lite hydraulic torque wrench, Hytorq

DELTA REGIS ECT300 TORQUE DRIVER POWER SUPPLY

K-Line KL5890 3/8 .377 Hard Chrome Plated Ball Broach: K-Line Tools

(15m) 45ft USB Cable Waterproof Drain Pipe Pipeline Plumb Inspection Snake LED

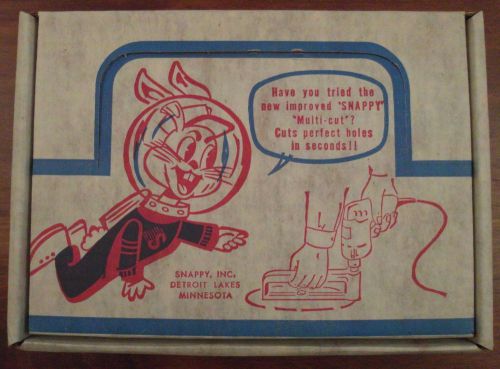

VINTAGE SNAPPY MULTI-CUT SM-3 NEVER USED WITH BOX AND INSTRUCTIONS AS IS

Ridgid 32920 Model No. 15 Tubing & Conduit Cutter, 3/16 - 1-1/8"

Hand Crank for Allis Chalmers B or C tractor

MILWAUKEE HEAVY DUTY 1/2" TWO SPEED RIGHT ANGLE DRILL DRIVE + CASE

6 pcs Epson DX4/DX5 Printhead Big Damper with Big Filter Original

6 pcs Mimaki JV33/JV5/CJV30 Joint Valve Assy/Ink Tube Connector Original

2 pcs Mimaki JV33/JV5/CJV30 Cap Capping Top Original

6 pcs/lot Mimaki JV33/JV5/CJV30 Wiper Original

2 pcs Mimaki Encoder Sensor for JV33/JV5 Original

6 pcs 2mm x 4mm Mimaki ECO Solvent Ink Pump Tube for Mimaki JV2/JV3/JV4 Original

Sioux Tapered Expanding Pilot Stem Size 1/2" Model No. E500 Fits No. 2 Taper

People who viewed this item also vieved

GRIPHOIST TU-28 Winch Rope Cable 3000/4000 LB. TESTED

ARMSTRONG GMTK GENERAL MECHANIC TOOL KIT WITH PELICAN CASE

for Milwaukee M18 18Volt Li-ion Battery C1418C replacement Charger NEW

Vertical Concrete Rough Coral Stone 9" Texture Roller

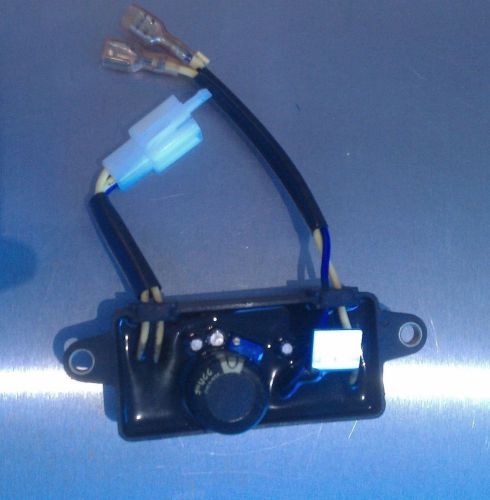

AVR AUTOMATIC VOLTAGE REGULATOR 4kw fits PREDATOR 212cc 4000w 3200w

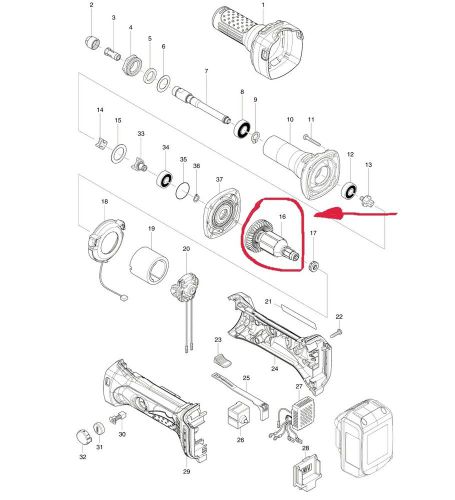

MAKITA ARMATURE 18V BGD 800 Cordless Grinder 18 VOLT ROTOR 619284-5

65pc 3" Deep Organizer Storage Bins Toolbox Tray Dividers fit Lista & Vidmar

Hilti GX 120 Fully Automatic Gas Actuated Fastening Nail Gun

HOT BEND PVC BENDING GUN 002953 47G3 WITH FISHER REGULATOR #93321

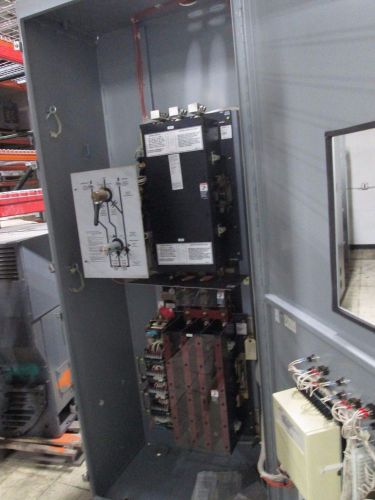

ASCO Automatic Transfer Switch w/ Bypass F434360097XC 600A 480V 60Hz 3P Used

Pair of Enerpac 1/2" - 2" Pipe Tube Bender End Posts - Z12071 - Blackhawk

DeWALT D25980 Paviment Demolition Chipping Breaker Hammer LEFT Handle N167287

Parker Domnick Hunter MiDAS PNEUDRI Compressed Air Dryer DAS 3 NPT 618310103

Stow 6 CF Concrete Mixer MultiQuip Bartell Packer Electric Start 8 HP Gas motor

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies