US $9,990.00

| Condition | New other (see details)

:

A new, unused item with absolutely no signs of wear. The item may be missing the original packaging, or in the original packaging but not sealed. The item may be a factory second or a new, unused item with defects. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “new capsule machine,220V” |

Directions

Similar products from Blenders

Bronwill Scientific Biosonik III Ultrasonic Processor Sonicator

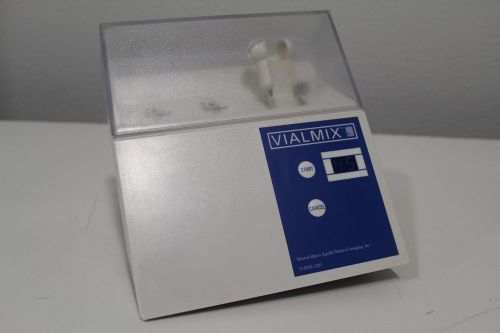

VialMix Mixer Bristol Myers Squibb for Definity + Free Fast Shipping! For Parts!

JANKE & KUNKEL IKA Werke ULTRA-TURRAX T25 HOMOGENIZER

Xcellerex XDM-Q-200 XDM Quad Mixer Single-Use Mixing System 200 Liter

Eppendorf Thermomixer Mixer 5350-21121

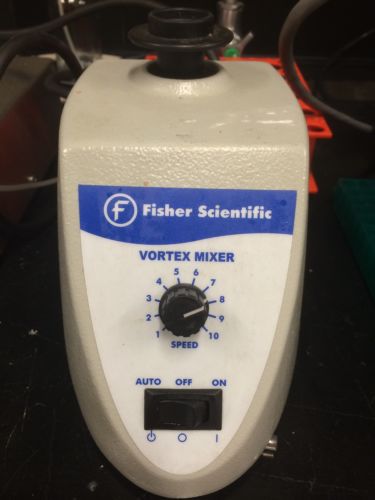

Fisher Stardard Vortex Mixer 120v

Lot 3 Glass Kontes Lurex 40 mL TISSUE Grinder Homogenizer set with masher sticks

New High Efficiency Smart Mixer MIX-3000 300-3000rpm PCR Plates Lap Equipment

Xcellerex XDM Quad Mixer Single-Use Mixing System 500 Liter

Amersham Biosciences Gradient Mixer GM-1

5 7/8" Dia. 4-Blade Impeller on 0.51" Shaft Stainless Mixer 31" Long 45° Pitch

3 3/4" Dia. 4-Blade Impeller on 0.312" Shaft Stainless Mixer 21" Long 45° Pitch

20pcs MCE Syringe Filters 13mm Diameter 0.22um non-sterilized

CIMAREC MODEL S131125 STIRRER MIXER

Deluxe Mixer, Scientific (L-2510)

New Lab Laboratory Homogenizer Disperser Mixer AM110W-H 50~2000rpm 0.5~10mm

Waring High Speed Tissue Culture Blender and 500 ML Eberbach Glass Container

BIOSPEC BioHomogenizer Output Shaft

Caulk Vari-Mix II-M Dental Amalgamator Mixer

NEW / NOS BECKMAN SPINCO MICROMIXER w/ timer MODEL 154A w/ Cover + Manual in box

People who viewed this item also vieved

H127833 Lot of (2) Pharmacia Biotech REC 102 Chart Recorder 80-1300-03

Newport 8-Channel Butterfly Fixture + (8) FP3-FH1 Bare Fiber Holders Diode Laser

Newport NRC 430 Mircrometer Stage with Platform 3" x 4"

Edwards Datametrics 1550C Vacuum Gauge Controller

Crest CP230D Ultrasonic Cleaner-Heat and Digital Timer-3/4 Gallon Tank

Sourcingbay 3 inch Handheld 500x 5M 8 LCD Digital Video Camera Biological

ERNST LEITZ TRANSFORMER TYPE 301-211-.001

Soil Cone Penetrometer LABGO 611

@@ EDWARDS MODEL IGX100M DRY PUMP -NEW? (#1650a)

Blending Karl Fischer Turbo 2 Capacitor

Thermo MX35 Ultra Microtome Blades 10 Packs Of 50 Blades New

Market Forge Sterilmatic Autoclave sterilizer Model STM-E

Bio-RAD Power Pac 200 Electrophoresis Power Supply

BENCHMARK SCIENTIFIC BLOTTER BR1000 - 2D FIXED SPEED PLATFORM ROCKER - 230V 50Hz

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies