US $60.00

Directions

Similar products from Grips & Tongs

Fixed Desk 1" Jaw Mini Vise For Jewelers Heavy Duty Craft Hobby Universal Tool

PALMGREN 610 VISE MACHINE , JAW W 6 In, JAW OPEN 6 In

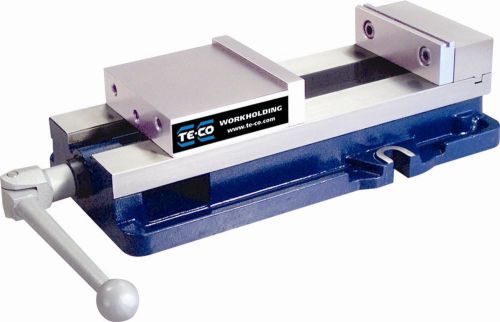

NEW TECO 6" SINGLE STATION VISE 9" JAW OPENING PWS 6900 "MORE TOOLING LISTED"

Erie superior vise no.44 with a 4 in. jaw 1210-2 5

Machinist Precision Vise - 6-1/4" X 2.5" Opens to 2-1/2" Vintage Made In USA!

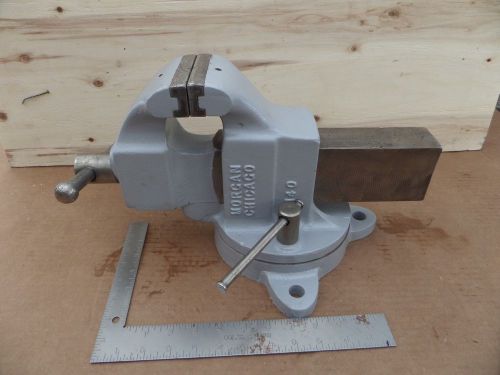

Vtg MORGAN No.140 4" Swivel Base Bench Vise Powder Coated Gray

4" Jaw Bench Vise With Swivel Base Polish Made HI-TEST NO327

Palmgren Tilting Angle Machinist Vise 2-7/16" Wide Jaws Opening to 2-5/8"

Deburring Tools NorGa With Blade and Inserts

Toolmex Workholding Mill Vise Jaws 8" Opening 10" 10 YEAR WARRANTY

WILTON BULLET VISE MACHINIST CHICAGO 5" JAWS VINTAGE SWIVEL BLACKSMITH 75lbs

Mitutoyo precision vise #986-102 , 3-1/2" wide

MACHINIST VISE 3 1/8" JAWS PRECISION VISE

Drill Press Vise 2 1/2 ” Hobby Crafting Craft Gun Vice 2.5 2 1/2 Hand Table Desk Model

RIDGID CHAIN PIPE VISE NO. B-C-2 & RIDGID NO. 2 STRAP WRENCH

VINTAGE YOST VISE 360° SWIVEL BASE, No. 203 1/2

Vintage Craftsman No.1 Pipe Vise

People who viewed this item also vieved

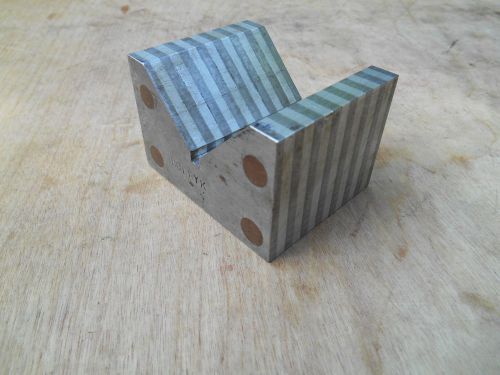

MAGNETIC TRANSFER V-BLOCK ,ALUMINUM AND STEEL , MACHINIST MADE

HARDINGE HV-4N 5C WORKHOLDING INDEX FIXTURE / INDEXER - HARDINGE THREAD NOSE

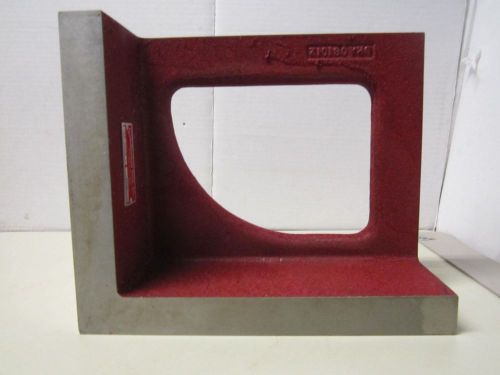

Suburban URA081012 Machined Universal Right Angle Iron 8" x 10" x 12" NEW

Royal Products 10215 5 MT Spindle Type Live Center With CNC Point

LATHE CUT OFF PARTING TOOL HOLDER 3/4" WIDTH + HSS BLADE : 3/32" x 1/2" x 4"

Lyndex 160-104 16C Round Collet, 1-5/8" Opening Size, 4.31" Length, 2.26" Top

Lyndex 800-032 R8 Collet, 1/2" Opening Size, 4.089" Length, 1.25" Top Diameter,

RARE SOUTH BEND PRECISION LATHE No. 3 13 PC. SET BRASS COLLETS IN 64th" SIZES

NEW NO NAME LOT OF 100 DBF-100 DBF100

Electriduct 16 Slot Manager (medium slots) - 2 Pack

MITEE BITE 53170 Multi-Fixture Clamp

Bison-Bial 25”, 4 Jaw Independent Lathe Chuck, Bison-Bial Model 4317, 10.5” Hole

Forkardt collet chuck, ZKSV110-42-K5-128

New 15" Cushman Accra-Set 3 Jaw Lathe Chuck 10-104-15-000Z A 11 Adaptor

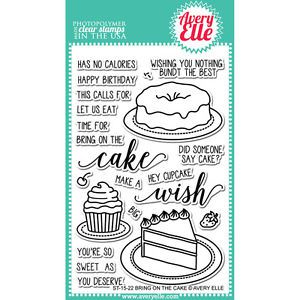

"Avery Elle Clear Stamp Set 4""X6""-Bring On The Cake"

Martha Stewart Circle Border Cartridge-Dotted Diamonds

"Woodware Clear Stamps 3.5""X5.5""-Baking Sampler"

Antique Scherr Company Magnetic Blocks Set magne blox made in U.S.A.

MACHINIST TOOLS LATHE MILL Machinist Large Toolmakers Ground Bench Block Set Up

PARALLEL BARS-BLOCKS LOT OF 13 PIECES 5 PAIRS - MACHINIST LATHE TOOLS

Fibrotor Rotary Indexing Table EM 15.0410.9.132.24.0.0.3

Walter Dividing Head UTA-100E 5" Walter Chuck + 8 plates & accessories

I Have This Lot Of 8 Different Wedgelock Fasteners

LNS Quick Load Servo S2 Magazine Type Bar Feed

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies