US $190

Directions

Similar products from End Mills Router & Drill Bits

LOT OF PCT & OTHER ASSORTED HSS WAVE CUT END MILLS .65 "

LOT OF HY PRO HSS COBALT ROUGHING END MILLS .95"

New - DoAll 5/8" x 1 3/4" HSS Ball End Mill EDP37058

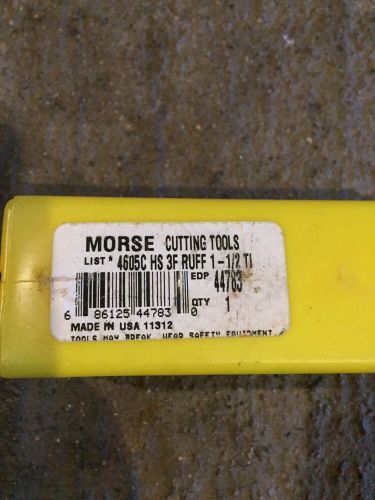

Morse Cutting Tools 4605c Ha 3f Ruff 1 1/2 End Mill Bit

33mm 1.299" Sandvik 880-D3300C5-03 Indexable Inserted Drill (O 816)

HHIP 5800-4060 3/16" x 1/2" HSS Corner Rounding End Mill

Resharpened carbide endmills end mill 3/4

OSG I Inch roughing cobalt endmill

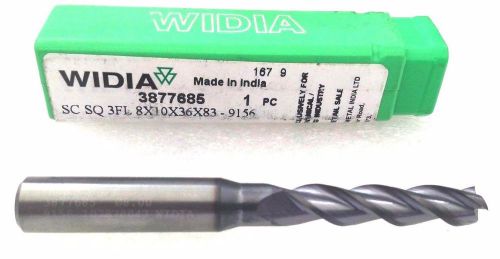

KENNAMETAL WIDIA SC ENDMILL 8MM 3FL TIALN 8x10x36x83

KENNAMETAL EXTRA LONG 12MM BALLNOSE ENDMILL HN431KIN26099 12x12x60-90x150 3FL

Mixed Lot - Keyseat Cutter End Mills -Roughing Single & Double End - HSS MORSE

GUHRING 16MM ENDMILL 2FL No03635 - 16,000

Interstate #1108-5100 1" x 1" x 4" x 6-1/2" 4F Uncoated Cobalt Long CC End Mills

Fullerton End Mill 4 30 Deg RH Flt drill bit

Interstate End Mills 10792048 3/4" x 3/4" x 1-5/8" x 3-7/8" 4F Uncoated HSS M2

Waukesha Sanitary Pump Stainless 10HP Baldor Motor Good Condition Very Low Price

Indexable face milll - Widia 3 1/4inch MIL-TEC 3 inch -19 new inserts Bridgeport

5PCS Extra Long 3mm 2 Flute HSS & Aluminium End Mill Cutter CNC Bit Extended

OSG #36702711 1/2" x 1/2" x 1" x 3" 4F WXL Carbide Corner Radius End Mill

People who viewed this item also vieved

Keyway Broach Bushing Guide, Type F, 4" x 6", Uncollared, Used

Keyway Broach Bushing Guide, Type F, 3 1/2" x 8", Uncollared, Used

SCGX 070308 P2 DP3000 SECO ** 10 INSERTS *** FACTORY PACK ***

Allied 182A-0100 Series #2 T-A Drill Insert 1" Dia. Cobalt TiALN

CERAMIC INSERTS. GREEENLEAF. 5 PCS. RPGN 2.52 T1A. $6 per insert. FREE SHIPPING

SNGA643 SP2 NTK SILICON NITRIDE CERAMIC TURNING INSERTS, price is for one insert

Round Die 7/16-14 UNC HSS 1/2" x 1-1/2" 23779 <1920>

Hex Rethreading Die 1-1/2-12 UNF Carbon Steel 2-9/16" x 1" 24191 <056>

YANKEE - 3/16 COBALT USA SS SP FL CHCK REAMER (2pcs)

INTERSTATE - TS CHK REAMER SP FL HS 5/8 (1pcs)

Jewelry Malco HSS 3 x 0.025 x 1 Slitting Slotting Saw Blades

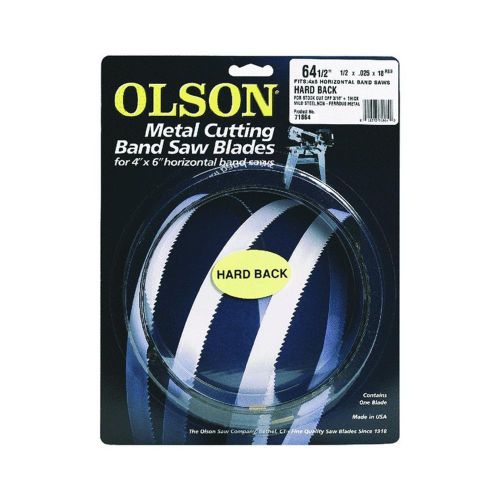

Olson Saw #71864 1/2x64-1/2 18tpi Blade

Lenox Vari Step Bit Set (Brand New NO RESERVE)

0.5MM X 60° CARBIDE FLAT BOTTOM ENGRAVING BIT 5x

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies