US $88,900.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Supertec |

| Model | G20P-50CNC |

Directions

Similar products from Toold for Grinding Machines

40000 RPM 12" L Heald 510 / I-5A-OM GRINDING Spdl

45000 RPM 9" L Cincinnati-Heald 473-251100-A GRINDING Spdl

80000 RPM 9" L Cincinnati-Heald 473-251100-A GRINDING Spdl

50000 RPM 9" L Cincinnati-Heald 401-251100-C GRINDING Spdl

50000 RPM 10.5" L Cincinnati-Heald 401-251100-C GRINDING Spdl

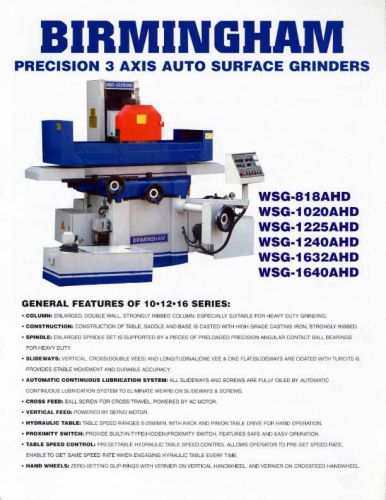

10" W 20" L Birmingham WSG-1020AHD 3 Axis Automatic SURFACE GRINDER, Magnetic Ch

8" W 18" L Birmingham WSG-818 Hand Feed SURFACE GRINDER, Magnetic Chk Included

6" W 18" L Birmingham WSG-618 Hand Feed SURFACE GRINDER, Magnetic Chk Included

12" W 24" L Supertec PLANOTEC 1224NC SURFACE GRINDER, 3-Axis Automatic, 7.5 HP

8" Dia. 20" L Supertec G20P-50NC OD GRINDER, Automatic Infeed thru Mitsubishi PL

6" W 18" L Supertec STP-618M SURFACE GRINDER, 3 HP, Roller Ways on Tbl

8" Dia Cap 10hp HP Supertec STC-1206 CENTERLESS GRINDER, 6" Wide Wheel

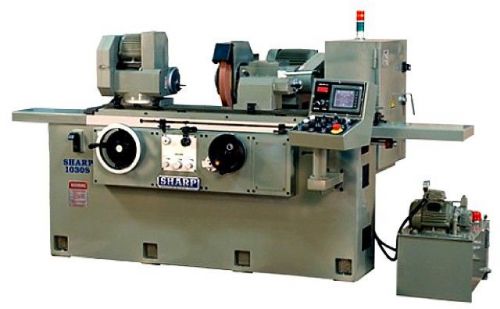

10" Dia. 30" L Sharp OD1030S OD GRINDER, Automatic Infeed system

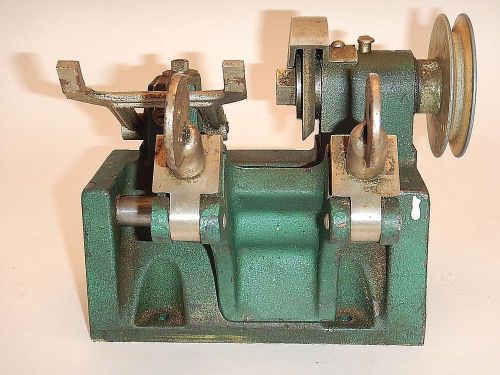

Vintage Keil Lock Co. Model 4F Key Cutting Machine, Copier, Duplicator

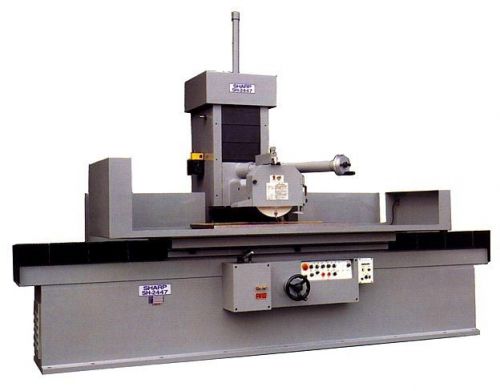

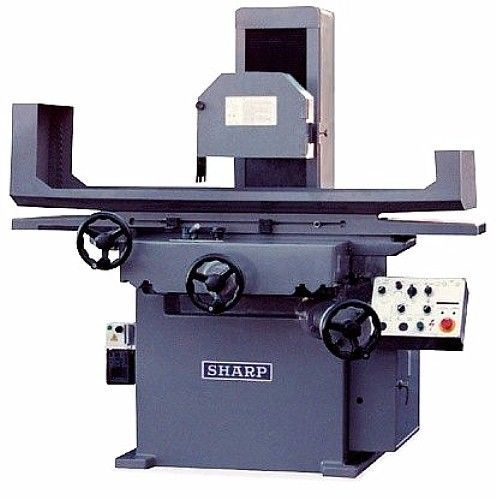

20" W 60" L Sharp SH-2060 SURFACE GRINDER, 10 HP, 2 or 3 Axis

12" W 24" L Sharp SH-1224 SURFACE GRINDER, 3 HP, 2 or 3 Axis

8" W 20" L Sharp SG-820 2A SURFACE GRINDER, 2 Axis Hydraulic

8" W 20" L Sharp SH-920 SURFACE GRINDER, 3 HP, 2 or 3 Axis

milwaukee die grinder , burr grinder tool pencil grinder VERY GOOD CONDITION

People who viewed this item also vieved

TURRET LATHE FLANGED TOOLHOLDER 1-3/4" ID X 4-1/4" X 3-1/8" DIA. BOSS #9568

South Bend 13" Large Bore Spindle, Bearings, Take-up Nut and 2 Gear Keys

CAST IRON LATHE LEGS- STEAMPUNK - TABLE LEGS

Shell Indexable Insert Mill - Radius .75" Dia Round Insert

Milling Machine Accessory - Air Power Drawbar A&T ANT-300 (R8, NT30,40).

Rohm Spiro 1/2" Keyless Drill Chuck - Jacobs #J6 Chuck Taper - COMPLETE

VINTAGE MACHINISTS DERBYSHIRE LATHE " ELECT" 18"Model ONLY! GE/MOTOR and PULLEY

1" Round NC NF & NS Dies & Die Stock Handles 1/4"-28 NF to 5/16"-32 NS

Sumitomo MDS4375LHV Carbide Coolant Drill New

Whitney Metal Tool Co Sheet metal Snap Lock Punch RARE

Danley Precision Die Set machinest tool Lathe Milling

Hydraulic Technology INC Hydraulic Press Model 8305 A Price Reduced!

DoAll C-305A Automatic Band Saw 12" X 12"

HEM SAW H1200A HORIZONTAL BAND SAW 12.75" X 11"

HEM SAW H101A HORIZONTAL BAND SAW 12.75" X 11"

Abrasive Air Sand Blasting Blaster Blast Cabinet Glass Bead Media WITH EXHAUST

18" X 24" CAST IRON LAPPING PLATE ***XLNT***

(5) EROWA Chucking Spigot F/A EDM M10 x 45 EDM TOOLING electrode holders cnc

(15) EROWA Chucking Spigot F/A EDM M10 x 45 EDM TOOLING electrode holders cnc

(20) EROWA Chucking Spigot F/A EDM M10 x 45 EDM TOOLING electrode holders cnc

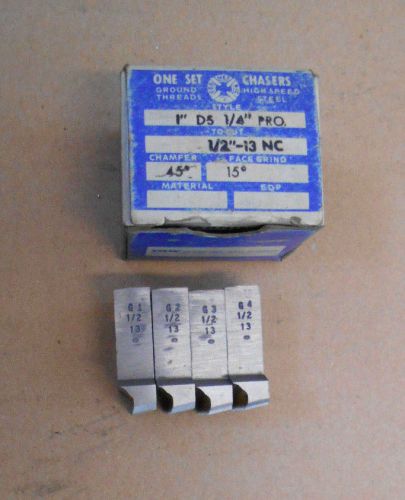

GEOMETRIC 1/2" 13 Projection chasers for 1" DS Threading Head. New

GEOMETRIC 1" DS BSPP Threading Chasers

Acme RB-8 Automatic Bar Machine. 1-5/8" Acme Gridley Automatic Screw Machine

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies