US $489.00

Directions

Similar products from Grinders - Professional

Osborn 6" Master Wire Wheel .014 Wire, 2" A.H.

RR-Tools Air Die Grinder Kit 1/4 Inch Heavy Duty 30014 D

4” Standard Double Row Concrete Diamond Grinding Cup Wheel 5/8”-11 Thread Arbor

Milwaukee 14-20-0780 Power Module Assembly for 6095, 6096, 6098 Grinders

DOTCO 2" VACU ERGO / ANGULAR PNEUMATIC GRINDER, P/N: 12L1280-36 ~NEW~IN~BOX~

Milwaukee Grinder Guard 7" 49-12-0010

Boyar Schultz Model 2 Profile Grinder; 1 HP

Segro Adbrasives 12in Wire Knot Wheel 2 PIECES per Box

Timesaver Grinder/Polisher, 960-1MW

Metabo 6" Angle Grinder 120V Model WE 14-150 Quick 6.00160.42

BLACK & DECKER 6" PORTABLE GRINDER 4278-60

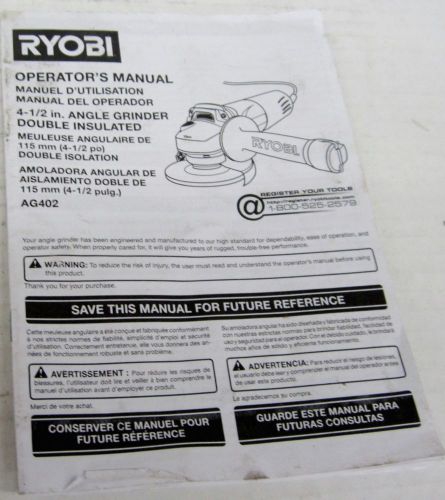

RYOBI 983000-997 OPERATOR'S MANUAL FOR AG402 4-1/2" DOUBLE INSULATED ANGLE GRIN

BLACK & DECKER 6" PORTABLE GRINDER W/ BENCH STAND 4278-67 , 4000 RPM 12A 120V

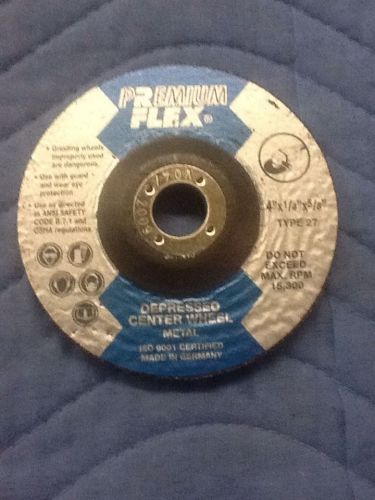

Continental Type 27 Grinding Depressed Center Wheel 175700 Qty 25

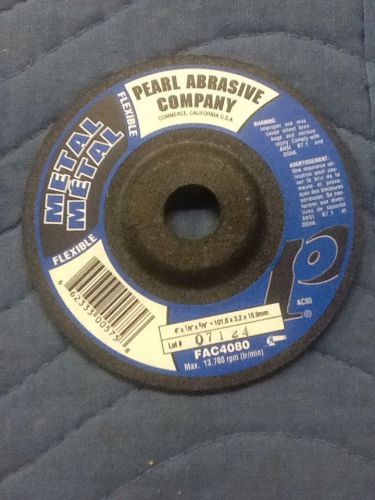

Pearl Abrasive Company Grinding Depressed Center Wheel FAC4080 Qty 20

Future Abrasive Company PSA Resin Cloth Grit A100X Disc 3x0 Qty 50

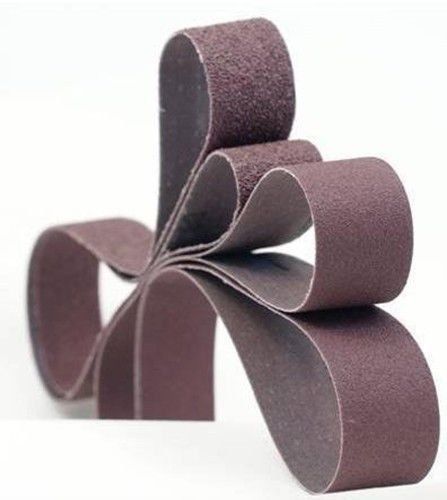

Fein Tools Fleece Belt-Medium 3'x79'

Sunnen Model CRG-750 Cap and Rod Grinder / Automotive tools tooling tool 750 cgr

Craftsman 315.25840 1/5 HP Hand Grinder Max 1 1/2 IN Hand Grinder

People who viewed this item also vieved

OX BODY - Hoist Cylinder Dump Truck

Tru Tint Concrete Dye - Midnight

GDS Racing HSS Steel Hexagon Key Screw Driver Set 1.5/2/2.5/3mm for RC Car Boat

PL-300GJ Battery Powered Beacon, Ultra Bright LED, 5" Diameter x 5" Height, Gr ,

Lambretta Progressive Fork Spring Set Series 1 2 3 & GP Springs

Master Appliance HAS011K Heat Element For Master Heat Gun 500-750°F

Vintage Kennedy No 536 8 Drawer Machinists Tool Chest w/ Key

Gasoline Power Station Model NAG7200 Generator

Imperial Eastman 1/2" tube bender Model 364-FHA 1-2

Honda EU2000i/EU1000i Generator 3/4" exhaust extension (3 foot)

SEARS Craftsman Power Hammer #3817 W/ Instructions & box POWER ACTUATED CONCRETE

Instrument Air compressor package

Monster Duty Wacker Jumping Jack Ground Compactor

JACK HAMMER CHISELS AND POINTS

Reliance Controls TCA1006D 100 Amp Utility / Generator Transfer Switch New

MILLER CURB 45018-09 6" AUGER 'NEW OEM'

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies