US $19,288.00

| Condition | New other (see details)

:

A new, unused item with absolutely no signs of wear. The item may be missing the original packaging, or in the original packaging but not sealed. The item may be a factory second or a new, unused item with defects. See the seller’s listing for full details and description of any imperfections.

|

| Seller Notes | “NOS never used” |

Directions

Similar products from Tools for Polishing & Finishing Machines

Bead blasting cabinet glove flanges media sand

Titanium 2" x 6" x 10" L Anode Basket

Sunnen Power Stroke Hone Model number MBB-1650, Serial number 52313X

Pangborn Spinner Hanger Shot Peen Machine

Lot of 4 Die Profilers, PBAX3500 in box 2 spares Jiffy "Super" w/60+ attachments

Lot of 3 Divine Dico 4" Cloth Buffing Wheels

Lot of 4 Divine Dico 4" Cloth Buffing Wheels

3M 3"x3/8" Scotch-Brite 33227 Plastic Radial Bristle Disc 360 Grade Box of 10

Sunnen Automotive Cylinder Hone

mold polishing machine, mold grinder

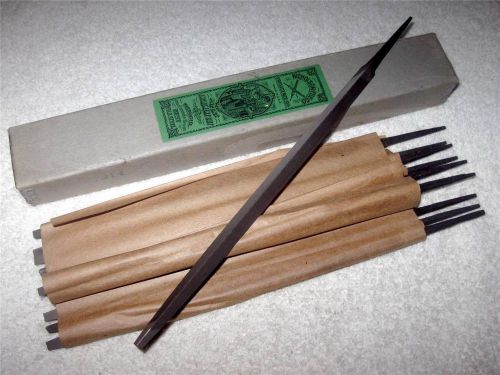

Vtg Nicholson Barnett 8" Double Extra Slim Taper File Lot w Box, 9 Total NOS USA

Vintage Nicholson 8" Extra Slim Taper File Lot with Box - 11 Total - NOS - USA

HUGE LOT D-M-E Jiffy Profiler D.M.E. Filing/Polishing BRUSHES NOS

Vintage Am Swiss #10 Cut 0 Double Curved File

10" Dia. 36" L Ex-Cell-O 74 CENTER LAPPER, SINGLE PHASE/115 -230 VOLTS

ACME (MADE IN USA) MODEL B-3, 10" 5 HP HORIZONTAL/VERTICAL BELT GRINDER

1993 SUNNEN CYLINDER KING MODEL CV-616E VERTICAL AUTOMATIC HONE FOR 3/4"- 8" DIA

People who viewed this item also vieved

5/8" indexable RH Tool Holder for Self-Lock Cut-off Inserts SLTHRH16-3

Freyman Radius BallTurning Fixture Holdridge Eagle Rock Shaplane

Putnam 8" 3 Jaw Metal Lathe Chuck Machinist Tool L-00 Clausing Southbend Jet Mon

Manuals for Cincinati Milicron 10-SP-90045 Lubricants Manual

Manuals for Cincinati Milicron SVC-1000 Instruction Manual

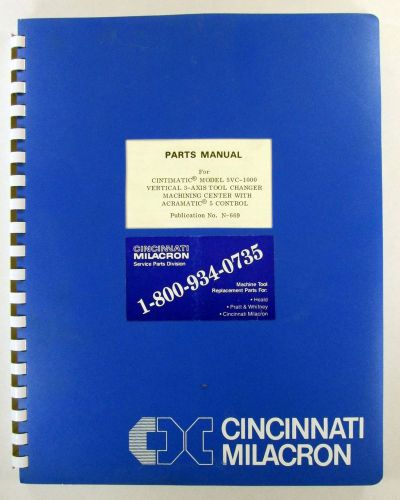

Manuals for Cincinati Milicron 5VC-1000 Parts Manual

Magnetic Chuck Control, Flux Master by MagnaLock

SMALL HEAVY DUTY ANGLE PLATE MACHINIST WELDER TOOLING SETUP JIG FIXTURE

MALCO Channel Shear with Compound Leverage SRC24A

SIMPLEX JACK, TEMPLETON KENLY & CO., CHICAGO, SALESMAN SAMPLE

Rivet Flush Set 1" polished face .401 shank rivet gun hammer 2-1/2" length SM90

Used Heli-Coil 3/8" 24 UNF Hand Thread Installer Tool 2299-6 4960-6

USED Helicoil 7551-06 6-32 UNC Thread Insert Installation Tool Prewinder

USED Helicoil 7551-04 4-40 UNC Thread Insert Installation Tool Prewinder

ROTEX A-18 MANUAL 8 TON,18" THROAT TURRETT PUNCH & FACTORY STAND

Pexto? Diacro? Tinsmithing not marked square head stake 4 3/4" x 2 1/4"

Pexto? Niagara? tinsmithing Early Setting Down tool, In good working condition

H & G CHASERS 100 SERIES SIZE 1/8" NPT PIPE

Used Box Tool 5146 5102-A Automatic Screw Machine

#22 ROUND COLLET SET, 22 PCS TOTAL.. 1/8" ...31/32". READ DESCRIPTION FOR SIZES.

#9368: W.F. Wells Bandsaw- Fabrication Equipment F-16-2A Used

#9546: Used Marvel 81/11 Vertical High Column Bandsaw- Fabrication Equipment saw

LOT OF DOALL BAND SAW POWER FEED PARTS

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies