US $9.97

| Condition | New other (see details) |

| Seller Notes | “THIS IS A MAILED CD, NOT PRINTED MATERIAL !!7 to 15 days mailing time” |

Directions

Similar products from How-To Guides & Manuals

CASE CX31 CX36 MINI EXCAVATOR OPERATORS MANUAL ON CD

Haas Lathe Operators Manual *892

Fb1316 Blu Ifr/Vfr Pilot Kneeboard/Blue

DEUTZ BF4M2012 BF4M2012 C BF6M2012 C ENGINE SERVICE MANUAL WORKSHOP REPAIR

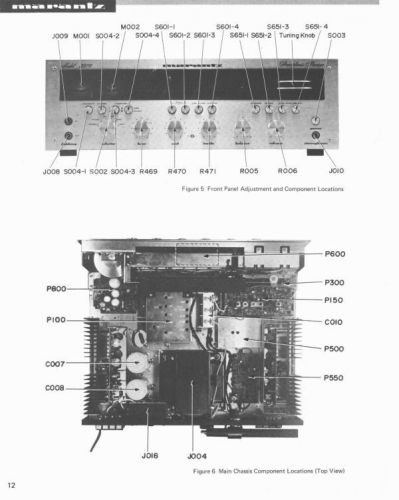

MARANTZ SERVICE MANUAL MANUALS AUDIO TECHNITION AMP AMPLIFIER REPAIR DVD

JOHNSON EVINRUDE 1.5HP to 40HP SERVICE MANUAL 1956 to 1970 OUTBOARD MOTOR BOAT

Detroit Diesel V-71 SERVICE WORKSHOP MANUAL ENGINE MOTOR OVERHAUL 1000 pgs

TRAILER BUILDING PLANS CAR FARM HORSE CAR HAULER cd

Espar Hydronic 10 & Hydronic M Water Coolant Heater Service & Parts Manual

DEUTZ 912 913 914 Service Manual Workshop Repair Manual Repair Cd

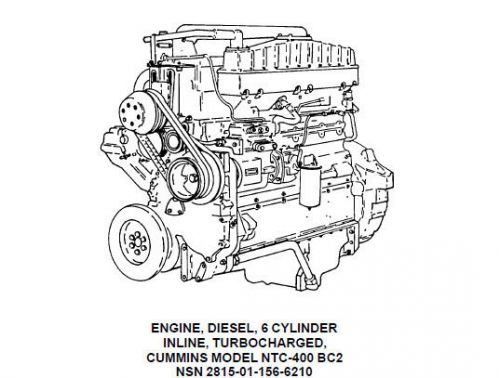

CUMMINS NTC-400 BC2 Diesel Engine Manual on CD 560 PAGES

M939 Series 5-ton Diesel Truck Service Manual Workshop CD 3655 Pages

Detroit Diesel Allison Model 8V92TA JAN 1988 Service Manual Workshop Repair CD

Brown & Sharpe Brochure For No.00,No.2,No.3 Ultramatic Screw machines w/ Tables

Brown & Sharpe Repair Parts Manual For No.00 Automatic Screw Machine Attachments

Cooper-Weymouth, Peterson Operation & Maintenance Manual For Model XHF-1212-RH

Yamazaki Machinery Works Operating Manual For Mazak Vertical Quality Center VQC-

Compressed Air Data 1939 Fifth Edition illustrated book by F.W. O'Neil

Gardern Denver Company Instruction and service manual for Model ET Electra-screw

Gardner Denver Company Parts List for Model ET100 Electra-screw compressor

People who viewed this item also vieved

SATO OEM Genuine Parts PE4730100 Ribbon Boss P00588001

Brady Fuse Blockout, Small (Pack of 6)

Herion, 80-267-87.0801, Pop-it 1", 120V, 312, 3 Way Valve, NEW in Box

Numatics, 152SS500M000061, 24VDC, 25Amps, Valve, NEW

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies