US $140

Directions

Similar products from Caulk & Sealants

Loctite Foamboard Adhesive PL300 10 oz, 6 Pack

Vintage Fletcher Electric Putty Softener (Tested: Working) Free Shipping

Forbo Marmoleum Sustain 885m Marmoleum Sheet and Tile Adhesive (1 Gallon Pail)

HILTI SCM 18-A METAL SAW ,FAST SHIPPING

Prevail Advance Performance Instant Adhesive Metroflor 30-GS Grip Strip

WEST SYSTEM SIX10® THICKENED EPOXY ADHESIVE

Armstrong Seam Coating Kit S-565 High & Low Gloss Deglosser Cleaner Accelerator

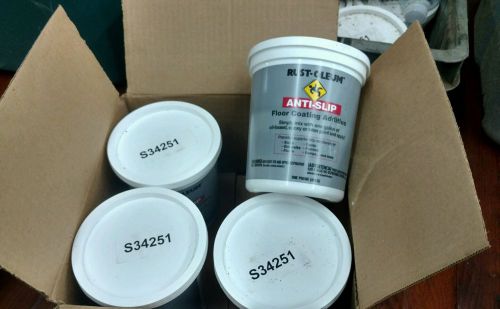

(4) Rust-Oleum Floor Coating Additive Anti-Skid 200

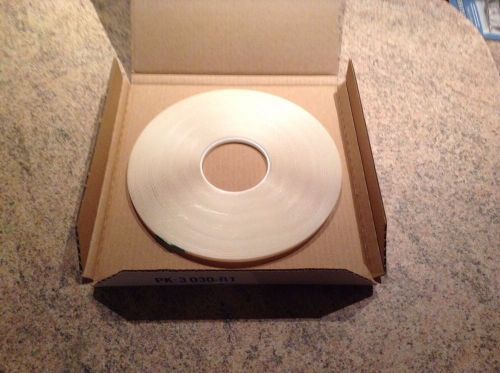

Clear Very Hi-Bond Acrylic Adhesive Tape 1/4"x.040"x 108FT

ACRYL-R SM5430 NON-SKINNING SEALANT

LOT of 6.....SealBest Elastomeric Blacktop Crack Filler - 10oz Caulk Gun Tube

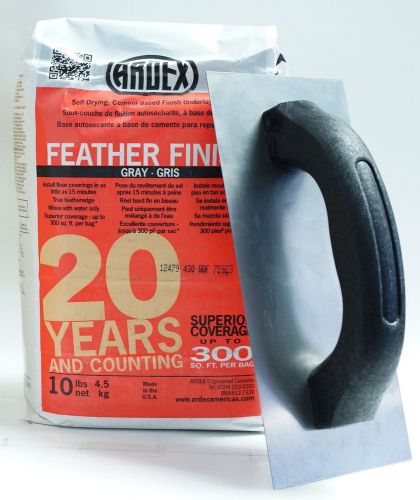

Ardex Feather Finish with Floor Patching Trowel

Sonolastic NP 1 Gun-Grade Polyurethane Sealant

TECLON SELF SEALANT MASTICSEAL. BUTYL RUBBER

3M Fire Barrier Sealant CP 25WB+ Intumescent RED 10.1 Fl Oz

Rubberseal Liquid Rubber Waterproofing Roll On Black 5 Gallon - New

GE ENDURIS HIGH SOLIDS SILICONE ROOF COATING

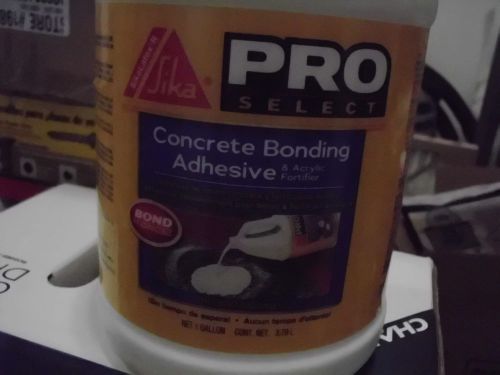

SIKA PRO SELECT CONCRETE BONDING ADHESIVE 1 GAL CLEARANCE NEW

People who viewed this item also vieved

Trap Vent 1-1/2" 14018 National Brand Alternative Interior Vents 14018

Louver Hood 531108 National Brand Alternative Utililty and Exhaust Vents 531108

Vintage German EU 250V 16A Plastic Cord End Female Connector Steckdose

German Vandal Resistant Outdoor Light Fixture

100x New Stainless Steel serrated flange hex lock nuts #1/4-20 High Quality Hot

100x New Stainless Steel serrated flange hex lock nuts #10-24 High Quality

Graco E-XP1 with 10.2 kW Heaters

Graco Hydraulic H-50 with 20.4 kW Heaters

(7) New R-140-TP BALLAST Lot advance tranformer lamp NOS nib

++ THREE CROUSE HINDS 54 X 27" EXPLOSION PROOF LIGHTS

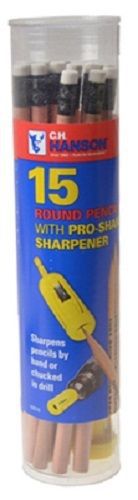

CH Hanson 30 Pack, Pro Sharp, 30 Round Pencils With 2 Sharpeners

CH Hanson 20 Pack, Medium Carpenter Pencils & VersaSharp Sharpener

Super Dry Diamond Polishing Pads 4 inch 7 Piece Set & Backer Granite Concrete

LAMINATE COUNTERTOP ENDSPLASH KIT, # 3526-58 TRAVERTINE 1000L RESK, BELANGER

Zipwall 4-Pole Professional Dust Barrier Kit

5.1" X 1.5" X 1/8" Corner Iron

BULLET PROOF GLASS 305mm x 229mm x 19.68mm LEFT OVER DEALER'S INVENTORY STORAGE

BULLET PROOF GLASS 254mm x 356mm x 19.80mm LEFT OVER DEALER'S INVENTORY STORAGE

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies