US $5,200.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | GENIUS |

| Country/Region of Manufacture | India | ||

| Model | GE-70SL |

Directions

Similar products from Sealing Machines & Bag Closers

91486 New-No Box, Multivac 11601063702 End Cap, 9-1/16" L

91493 New-No Box, Multivac 86755001000 Output Module

91501 New-No Box, Multivac 75810101070 Rewind Knob, M16-2.0 Thread

91556 New-No Box, Multivac 11631288000 Valve Bracket

91566 New-No Box, Multivac MO200-02-00 Control Board, 10770626, B0020131

91725 New-No Box, Multivac 19431106440 Spacer Bushing

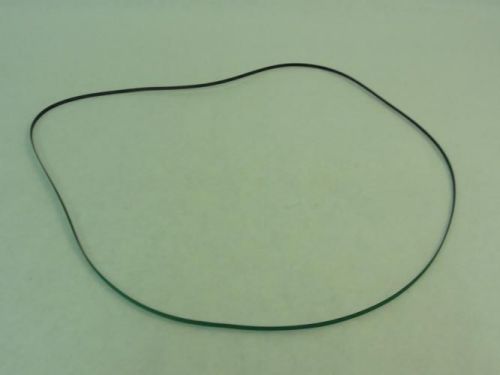

91755 Old-Stock, Multivac 200150701 Flat Belt

91111 Old-Stock, Multivac 19431125410 Socket Bushing

Three 8" x 50' Rolls for FOODSAVER - Giant Bulk Pack of Vacuum Sealer Bags

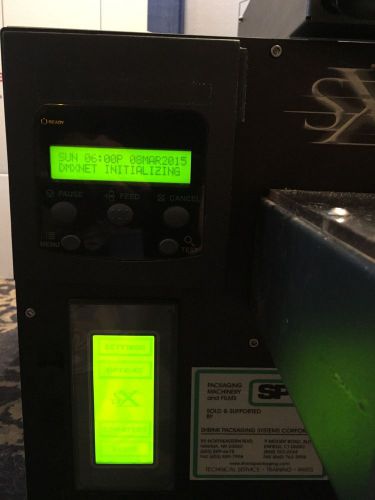

Sharp SX Table Top Auto Bagger, Label, Seal, w/ethernet

Automatic Molasses/ shisha Tobacco pouch filling & sealing machine

12" Heat Sealing Hand Impulse Sealer Machine Poly Free Element Teflon & Grip

91112 Old-Stock, Multivac 106684159 Lot-2 Spacer Bolts

91133 Old-Stock, Multivac 11601047001 Spacer Bolt

91135 Old-Stock, Multivac 11601047002 Spacer Bolt

91136 Old-Stock, Multivac 11611038100 Cam Pin

FS-200 Adjustable Heat Sealer 8" (200mm) Impulse Manual Bag polypropylene celo

Kihlberg Carton / Box Stapler FREE SHIPPING

vintage galvanized Offset funnel on metal BASE w flex spout - Planter? repurpose

People who viewed this item also vieved

375 X 3/4" Banding Clips 2 1/4" Seal Semi Open Galvanized Strapping 11lbs Crimp

400 X 1 1/4" Banding Clips 2 1/4" Seal Semi Open Galvanized Strapping 21lb Crimp

Stanley Bostich FC95EC High Volume Carton Stapler

Sealed Air UltraLite Void Fill Packaging Foam A & B 55Gal Drum Barrel

Automatic Vacuum Packager DZ400E/B New

*NEW Signode VT 19 Air Tool 3/4" (Orgapack) (Signode BXT) (Fromm P) (Polychem)

1/2x.020 Regular duty Steel Strapping, 2942 ft. = 1 coil = approx 100 pounds

Uline H-540 Industrial Poly Strapping Tensioner

3/4" YBICO Heavy Duty Steel Strapping Tensioner, Crimper Tool & 250' Strapping

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies