US $150.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Dural |

Directions

Similar products from Glueing Tools & Cements

Gasoila Epoxy Putty for Plumbing , UnderWater Repair, Automotive, Industrial NEW

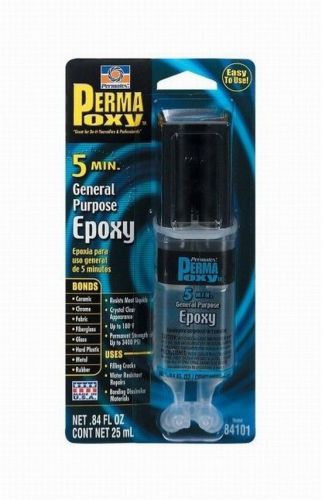

Permatex inc 84101 0.84 oz. PermaPoxy 5 Min General Purpose Epoxy, Clear

faux suede adhesive upholstery 1yd car auto interior fabric sofa couch DIY 57"

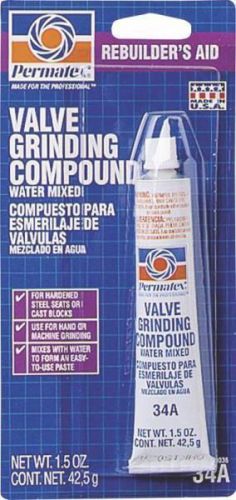

Permatex 80036 #34A Valve Grinding Compound 1.5oz Removes Surface Defects

(2) Permatex 80036 #34A Valve Grinding Compound 1.5oz Removes Surface Defects

(3) Permatex 80036 #34A Valve Grinding Compound 1.5oz Removes Surface Defects

(4) Permatex 80036 #34A Valve Grinding Compound 1.5oz Removes Surface Defects

(5) Permatex 80036 #34A Valve Grinding Compound 1.5oz Removes Surface Defects

(6) Permatex 80036 #34A Valve Grinding Compound 1.5oz Removes Surface Defects

3M JET-MELT Adhesive 3792LM Q NEW

Weld-On 413 Low VOC Clear PVC Cement lot of 2 Quart 32 oz Containers

J-B Weld 50112 ClearWeld Quick Setting Epoxy

10 grams -Thermal Conductive Glue Adhesive (epoxy substitute**) LED,GPU,Heatsink

SUPER GLUE PLUS, LOT OF 6 TUBES VICTOR FAST SETTING SUPER GLUE, NEW IN BOX

Cyanoacrylate Adhesive Instant Super Glue 20 gram instant adhesive

Oatey SCS 35610 Hercules Tan Regular Body Furnace/Stove Cement, 1 gal Bucket

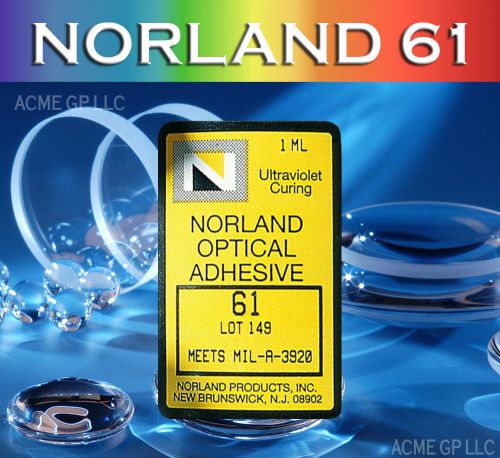

Norland 61 Optical Adhesive Glue - UV Cure - with 2 fine tip pipette applicators

Boat Cover Bimini Bandage C-102

J-B Weld 40001 Wood Restore Liquid Hardener 16 OZ

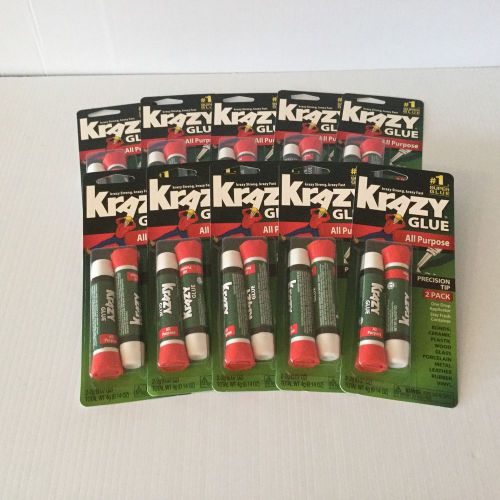

NEW LOT OF 10 PACKAGES ALL PURPOSE KRAZY GLUE PRECISION TIP 2 PACK - GLUE STICKS

People who viewed this item also vieved

GE GE21865 Maxflex Kitchen and Bath Siliconized Caulk, Almond, 5.5 Oz

GE GE14183A Kitchen And Bath Caulk, White, 5.5 Oz

Silicone All Purpose Clear Tout Usage

Momentive Fluorosilicone Adhesive Sealant FRV1106 06S-Crtrg .500 Lb

3M Aerospace Fuel Tank & Fuselage Sealant (AC236B1-2G) 1 Gal

* Black*Silicone self-Fusing Tape* 10 rolls & 2 free rolls

DENSO-Band mastic tape for gas and water pipes 10 meter, 10 cm. width (NEW)

NEW Shurtech Duct Duck Tape 5 Pack Sheets 8.25" x 10" Island Lime Green

3M Highland - Economy Masking Tape, 3/4" x 60yds, 3" Core - Cream 2600

Lot 4pcs Teflon Tape Pipe Thread Tapes 1/2" x 42" for Shower Head Nozzle Sales

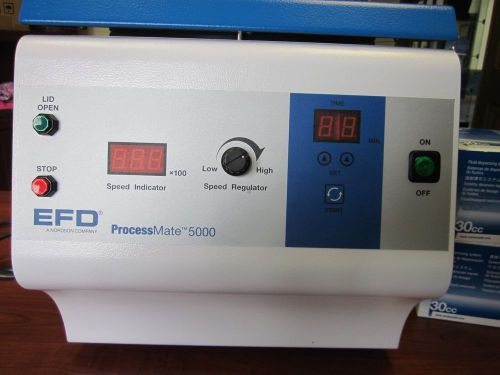

Nordson EFD Universal Certrifuge Model 7015541

Cox Pneumatic Caulking Gun NOS

Milwaukee Heavy-Duty Caulk and Adhesive Gun - 6562-21

EFD 800 Fluid Dispenser Tested, Needs New Air Control Relay MAC 35A-AAA-DACA-1BA

10 Nordson static disposable plastic spiral bell mix nozzles TAH 160 series

LOCTITE HENKEL 98048 ZETA 7021 SPOT RADIOMETER

Devon Silicone Adhesive - Clear

Seal Krete 40202 Clear Grip Non-Skid Grip Additive for Sealers Paints & Epoxies

Staples Washable Glue Sticks Jumbo Clear 1.4oz 6/Pack glue Stix case lot SALE

Loctite 277 Threadlocker Red 50 mL 1.69oz Bottle

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies