US $75.00

Directions

Similar products from Caulk & Sealants

White Tremco® Spectrem® 2 High Performance Silicone Sealant

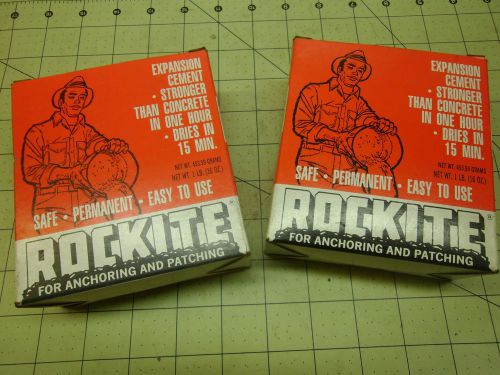

ROCKITE EXPANSION CEMENT 1 LB BOX (QTY 2 BOXES) #1854

Dow Corning® 795 Sandstone Silicone Building Sealant - 3 Pack

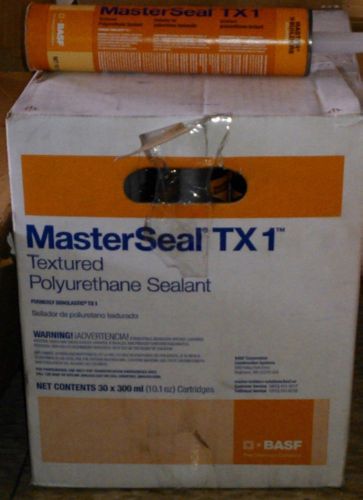

Masterseal TX-1~Textured White 10.1oz(Case of 30)Sonoplast~UNBEATABLE DEAL~GREAT

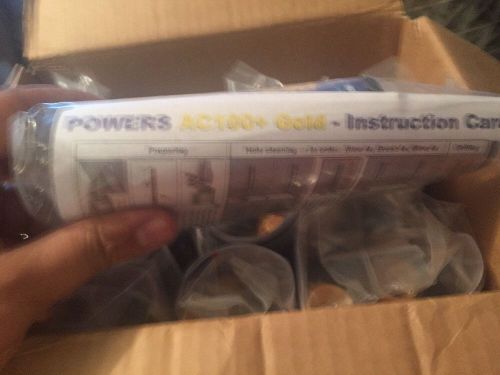

POWERS AC100+GOLD Vinylester Injection Adhesive Anchoring System (44A)

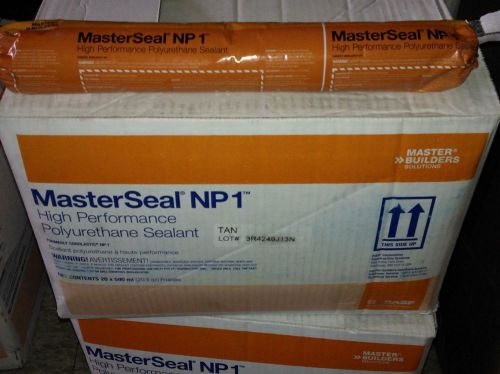

Masterseal NP1~TAN-20 fl oz(Case of 20)SAUSAGE ROLLS~UNBEATABLE DEAL~GREAT PRICE

TYTAN PROFESSIONAL Window And Door Spray Foam .20 Oz

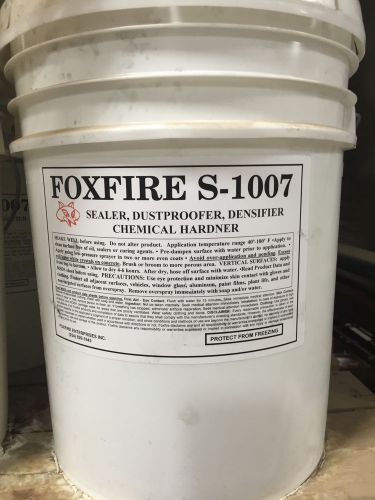

FOXFIRE S-1007 SEALER SEALER, DUSTPROOFER, CHEMICAL HARDENER, DEN

FOXFIRE EFFLORESCENCE REMOVER - (5 Gallon Pails)

Liquid Nails Heavy Duty Construction Adhesive

FOXFIRE GRAFFITI STRIPPER (5 gal pail)

Quikrete Polyurethane Self leveling Sealant, Gray-Lot of 2

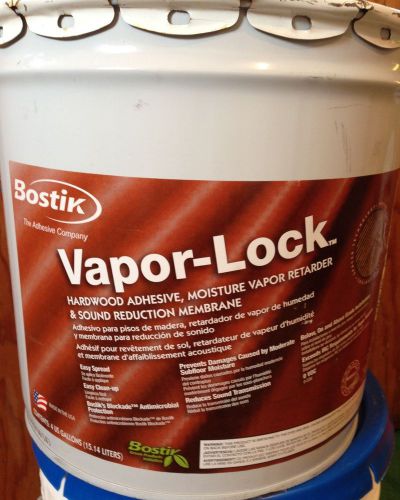

Bostiks Vapor-Lock hardwood flooring adhesive

Hilti HIT-HY 150 MAX FAST CURE HYBRID ANCHOR ADHESIVE

Simpson Strong-Tie SET-PAC-EZ, SET Epoxy-Tie Anchoring Adhesive 8.5oz w/2 Nozzle

CRL ALUMINUM STONE DYMONIC FC FAST CURING LOW MODULUS HYBIRD SEALANT CONCRETE

NEW~~Hilti HIT-HY 200R Injectable Mortar #2022793 Made in Germany 330 ml/590 g

COX 34 OZ. BULK / SAUSAGE CAULK GUN

People who viewed this item also vieved

Sylvania 18152 40-Watt Clear Tubular Intermediate Base Incandescent T6.5 Bulb

3M Scotch Fire Retardant Electric Arc Proofing Tape 77 1 1/2" x 20' Black

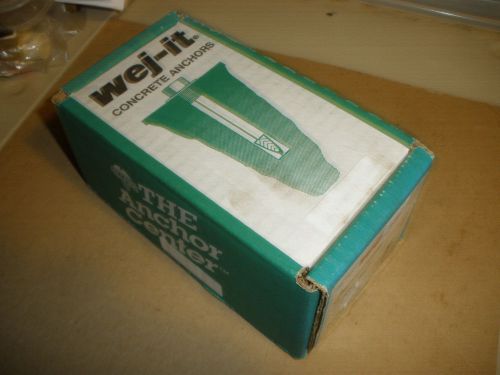

Wej-it 1/2" X 5" H1250 zinc concrete wedge anchors (10) pcs. 1/2-13

Wej-it 1/2" X 3-1/2" H1232 zinc concrete wedge anchors (12) pcs. 1/2-13

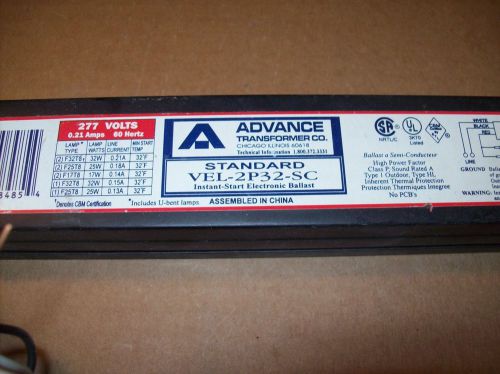

Advance VEL2P32SC T8 Electronic Ballast 277 volt

TFR400M Lithonia Commercial Grade Floodlight (New in box)

SCHLAGE #AL80BD SAT 626 STOREROOM LOCKSET

Uhaul Flat Screen Tv Cover TVC Fits up to 55" (36"x65") 1/16" Foam Protection

Premium Holly American lumber white wood 4/4, 1" x 2-1/4" x 74" - KD

NEW! 14 x 8 White AmeriFlow 2way Metal Vent 382W14X8-R Sidewall Ceiling register

12" x 24" RETURN FILTER GRILLE - Easy Air FLow - Flat Stamped Face

1-3/8" Core Drill Bit Core with 5/8"-11 Female Thread

2" Zero Tolerance Wheel (5/8" - 11 Thread)

2 GORGEOUS Vintage Solid GLASS BLOCKS Mid Century Architectural 8 x 8 x 3.25"

10 GORGEOUS Vintage Solid GLASS BLOCKS Mid Century Architectural 8 x 8 x 3.25"

1/4" HBR Closed Cell Backer Rod 20 Ft Free Shipping Nomaco Construction Foam

1/2" HBR Closed Cell Backer Rod 20 Ft Free Shipping Nomaco Construction Foam

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies