US $149.00

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Brand | Honeywell |

| Model | UDC3300 |

Directions

Similar products from Temperature and Humidity Controller Thermostats

AC 85-242V 0-70°C thermostat temperature controller temp control Thermometer

0-70°C Automatic Switch Heating cooling Thermostat temp temperature controller

Thermostat temperature controller temp control Switch Socket Thermometer+sensor

110-220V temperature control temperature controller temp Thermostat -19.9-99.9°C

-19.9-99.9°C Thermostat digital temperature controller temp thermometer +sensor

85-242V 0-70°C thermostat temperature controller temp control Thermometer +sensor

2200W -19.9-99.9 °C Thermostat temperature controller temp control thermometer

0-70°C smart thermostat digital temperature controller temp control Thermometer

AC 110-220V -19.9-99.9°C temperature control digital temp temperature controller

85-242V 0-70°C thermostat temperature controller temp control Thermometer US Plug

Chromalox Temperature Control ARC-215 277VAC 30A 60-250F

Vintage United Electric Controls Model 6263 Type E32N ????

AC 110-240V Digital PID Temperature controller + 25A SSR + K thermocouple Sensor

Nanmac H34 Temperature Controller

Omega IR thermocouple OS36-01-T-140F

Supco TAL2 Dual Temperature Alarm Logger, -50 to 86 Degree F, 110V

NEW Yamatake Honeywell SDC15 Single Loop Controller 115/230V C15SVOTA0100

Pro-Shield Landscape Fabric 4 foot wide X 40 foot length New Fast Shipping

HONEYWELL TEMPERATURE CONTROLLER UDC 1200

AC110V WH7016C Digital Temperature Controller Thermostat Range -50~110 deg C

People who viewed this item also vieved

Allen Bradley 1768-L43 Ser A CompactLogix 5343 Processor 1768-L43A 2MB w/ Key

BANNER QS12VN6LPQ 10-30VDCV MINI-BEAM EXPERT POLARIZED RETRO SENSOR

(6) Siecor 5097-A7792-010M 10M Cable 2F RIB Fiber STPC/MTRJ

SIMATIC NET SIEMENS PROFIBUS PCMCIA 1P 6GK1551-2AA00 CP5511 / CP5512

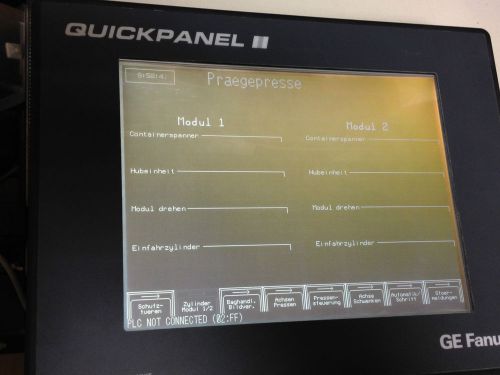

GE Fanuc Quick panel GP570-LG21-24V GP570LG2124V

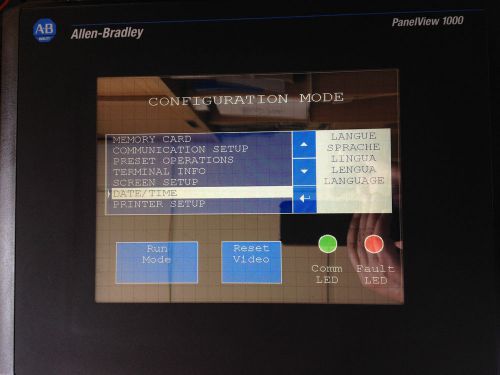

Allen Bradley PANELVIEW 1000 2711-T10C8L1 SER C REV C FRN 4.20 **READ**

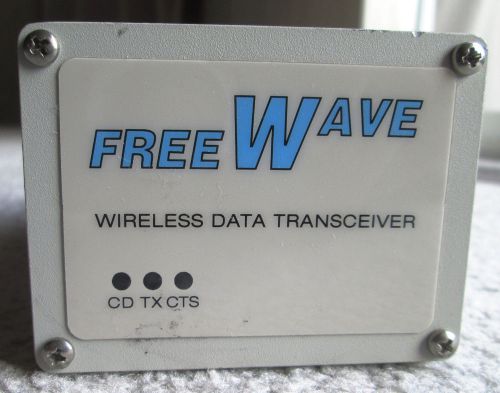

FREEWAVE DGR-115R 900MHZ SPREAD SPECTRUM RADIO WIRELESS TRANSCEIVER 902-928MHz

iFm Electronics Part Number ASB8 8/LED 5-4 P25 Sensor Box. New

NEW Robo-Soul TK-100 Black Crawler Robot Chassis Triangle Mobile Platform

Robot Kit Robot Learn Kit Smart Turtle Car Wireless for Arduino Robot Learning

Omron EE-SX872P sensor with 2M cable lot of 8

Omron EE-SX871P sensor with 2M cable lot 15pcs.

10 x Signal Lamp 7mm Mounting Hole Round XD7-1 Indicator Light 2 Pins Green 220V

2 x Red OFF-(ON) NO 2 Pin SPST 2A 125VAC Mounting Hole 12mm Push Button Switch

SXP 9573-170 WALTER PNEUMATIK VALVE ( NORGREN ) NEW FREE shipping = )

VELAN L12-0310C-13SL 8 BOLT 150 STAINLESS 4 IN KNIFE GATE VALVE B206617

BRAD/MOLEX 1300000072 4P MALE STRAIGHT 12' NEOPRENE 14/4 AWG CORDSET 32636

BRAD/MOLEX 1300070202 8P MALE STRAIGHT 12' 16/8 AWG CORDSET 208002A01F120

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies