US $23000

| Condition: |

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is

applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details.

...

|

Country/Region of Manufacture | Canada |

| Model | VW-18 | ||

| Brand | Hydmech |

Directions

Similar products from Tools for Saws & Cutting Machines

GROB Vertical Bend Saw For Metal Cutting

DoAll 916 bandsaw, needs work, rebuildable

#AH-320H COSEN 12.6" x 12.6" Horizontal Band Saw w/ Hyd Shuttle Feed (New 2008)

#H300A STARTRITE 9" x 13.75" Horizontal Band Saw w Automatic Bar Feed (New 1985)

Bolton Tools Band Saw 5 x 6 Metal Cutting Horizontal Band Saw

Bolton Tools Metal Cutting Slow Speed 14" Cold Cut Saw Swivel Base Cold Saw

ROCKWELL Jig BAYONET SAWS MANUAL & GUIDE c/w ORIGINAL ENVELOPE #RR34

Bolton Tools 11" Slow Speed Metal Cutting Cold Saw With Swivel Base

Carolina Industrial Horizontal band saw HD10

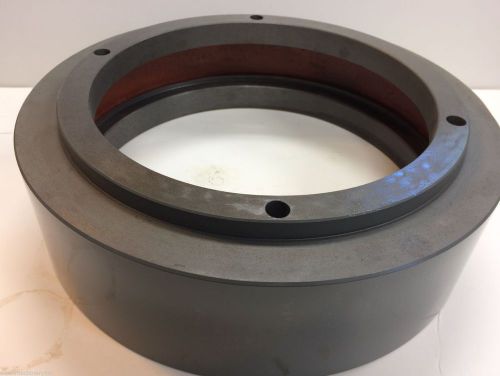

Band saw wheel 1-1/2" Bore 11-1/2" OD 1" wide 3/4" wide Blade track cast Iron

GROB INC 18" VERTICAL BAND SAW W BLADE WELDER & LIGHTS MODEL NS18 - 2030 FPM

LETEN MODEL DCM-10 VERTICAL BAND SAW TWIN TABLES 38 INCH THORAT

16” Doall Vertical Band saw, Model 1612-0, Extra Height

KASTO TYPE PSB 260AU AUTOMATIC POWER HACK SAW IRON PIPE I BEAM HACKSAW MACHINE

Greenlee 1339 vertical horizontal portable bandsaw band saw iron pipe Save $$$

Wells 11x7 model A7 horizontal bandsaw band saw iron pipe cutter extra blades

PISTORIUS MODEL 3C 12 PLH SEMI AUTOMATIC 12" INDUSTRIAL CHOP SAW FOR ALUMINUM

People who viewed this item also vieved

WALTER SVMSP-138R-45CF CHAMFER MILLING MINI-MILL CUTTER

Milling Machine Riser Block 4" for Bridgeport-Type Knee MIlls 4inch

Webb Vertical Milling Machine w/ ProtoTrak Plus Control & Power Feeds, & Drawbar

HANSVEDT EDM MACHINE Model SM 150B

System 3R Macro to Erowa ITS 50mm adapter

Perseo-Erie DrillMate EDM Machine Hole SMD35Z2+50DI SMC50DI Drill Popper

KENNAMETAL LATHE TOOL HOLDER DTFNL-245D STK 1581

Original South Bend 9" A B C Lathe Steady Rest

KENNAMETAL LATHE TOOL HOLDER GROOVING/THREADING NRL-243D STK 1583

#1 Acorn Dies 3/16-32 Used Reground

Hardinge CC-25R Right Hand Extension Tool Holder

Kellogg American 10 HP Air Compressor

SPI TAP ADAPTER BILZ SIZE 2 FOR 3/4" TAP TPD24-3/4" STK 8731

SPI TAP ADAPTER BILZ SIZE 2 FOR 5/8" TAP TPD24-5/8" STK 8730

Nitto Kohki WA-3500 ATRA ACE MAGNETIC BASE DRILL

Only for professionals!!! Single point diamond dresser.Type4 - threaded 0.85ct

Only for professionals!!! Single point diamond dresser.Type 1-cylindrical 0.15ct

Only for professionals!!! Single point diamond dresser.Type 1-cylindrical 1.10ct

SUNNEN K20-650 A H MANDREL COMPLETE,ADPT,MANDREL, WEDGE, RETAINER,STONE,TRUEING

SUNNEN K-12-370 MANDREL COMPLETE,ADPT, MANDREL, WEDGE, RETAINER, STONE, TRUEING

SUNNEN K-12-385 AH MANDREL COMPLETE.ADAPT.MANDREL, WEDGE, RETAINER, STONE, TRUEI

3/4" x 12' Accurshear Hydraulic Shear 875012

Mazak 5' x 10' Laser Load/Unload System

SCOTCHMAN HYDRAULIC IRONWORKER MODEL 9012

GEOMETRIC 3” Collapsing Tap Stationary and Rotary Type 1-3/4” Straight Shank

GEOMETRIC 3” Collapsing Tap Stationary and Rotary Type 2-1/4” Straight Shank

GEOMETRIC 3” Collapsing Tap Stationary and Rotary Type 1-3/4” Shank

By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Accept All Cookies